Brick molding device and molding equipment

A brick forming and receiving device technology, applied in the fields of forming equipment and brick making equipment, can solve problems such as reducing friction force, and achieve the effects of reducing friction force, improving production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions and beneficial effects of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

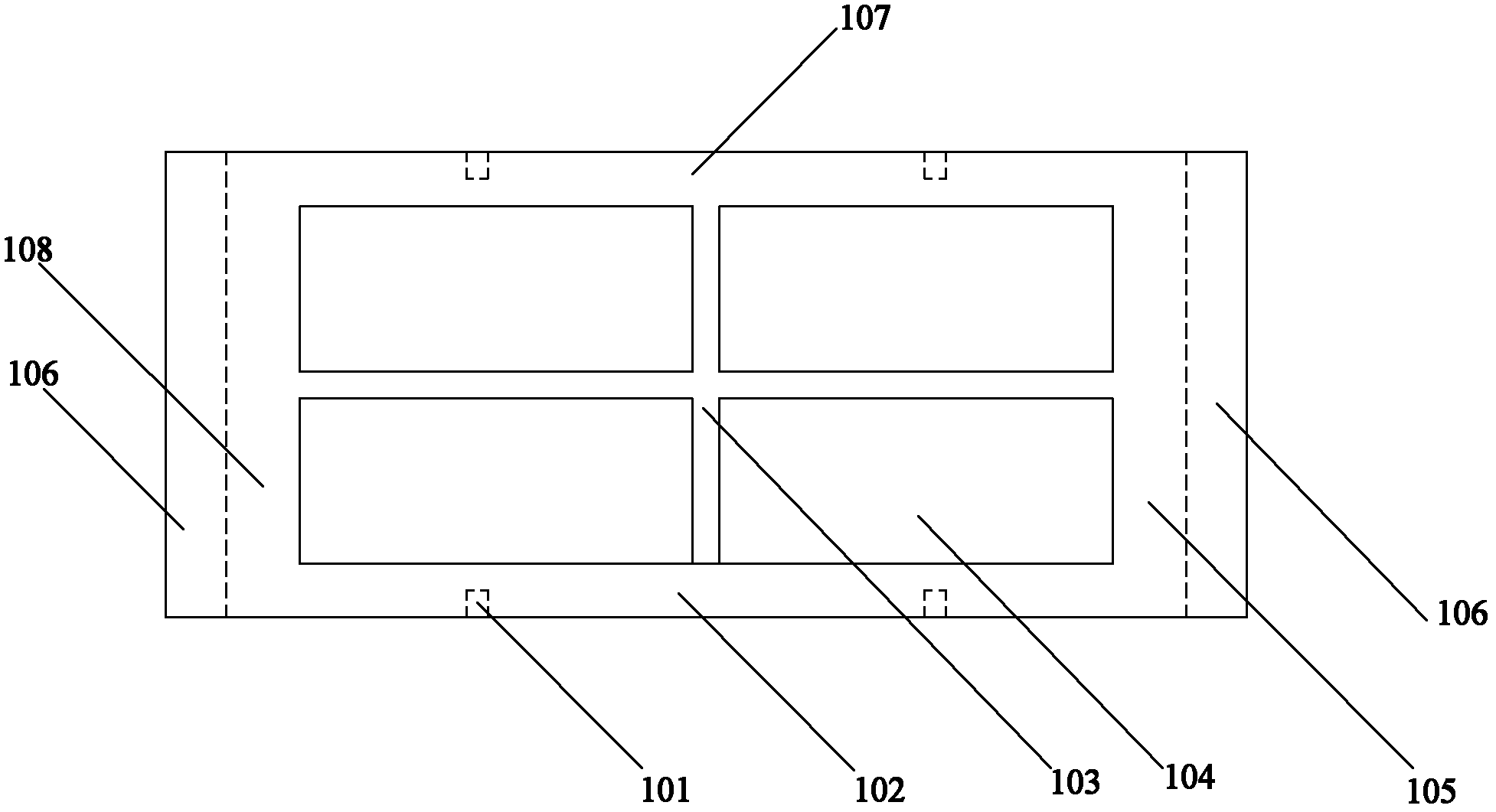

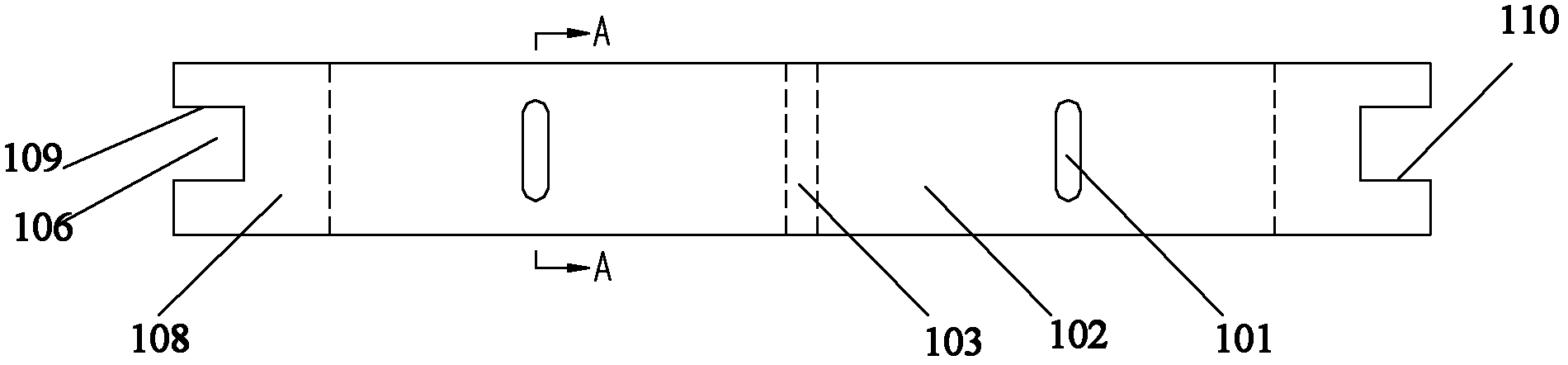

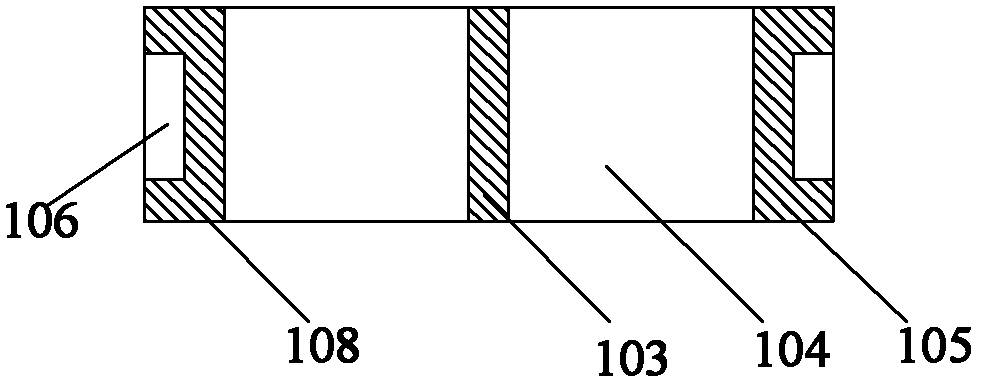

[0054] See attached Figure 1a , 1b , 1c, is a schematic top view of an embodiment of the brick forming mold frame matched with the forming equipment of the present invention, in this embodiment, the first side wall 108, the second side wall 105, the third side wall 102, the fourth side The walls 107 together form a mold cavity. The mold cavity of the illustrated embodiment is divided into 4 sub-cavities 104 by a partition 103, so that 4 brick adobes can be formed at one time. Of course, if more or less brick adobes need to be molded at one time, It is also possible to increase or decrease the number of sub-cavities 104 by reducing or increasing partitions, or even not to set partitions 103 . In order to realize functions such as receiving, pressing, and lifting of the mold during the moving pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com