Cartilage-bone-marrow composite tissue structure based on 3D living cell printing and method of cartilage-bone-marrow composite tissue structure

A composite tissue and 3D printing technology, applied in the field of biomedical engineering, can solve problems such as material interference, and achieve the effect of avoiding collapse and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] This embodiment discloses a method for preparing cartilage-bone-bone marrow composite tissue based on biological 3D printing, including the following steps:

[0039] 1. Biological information collection and modeling:

[0040] 1) By optimizing the bone structure image acquisition method, using perfusion casting and omics three-dimensional cross-sectional reconstruction technology, the three-dimensional data of the internal and external structures of the epiphysis of the human tibial plateau and blood circulation tube network are collected in a personalized manner;

[0041] 2) Input the collected biological information into computer software, express the actual tissue appearance and microenvironment as a bionic multi-material, multi-scale geometric model, and establish a bionic three-dimensional mathematical model of cartilage-bone-bone marrow and its microvessels.

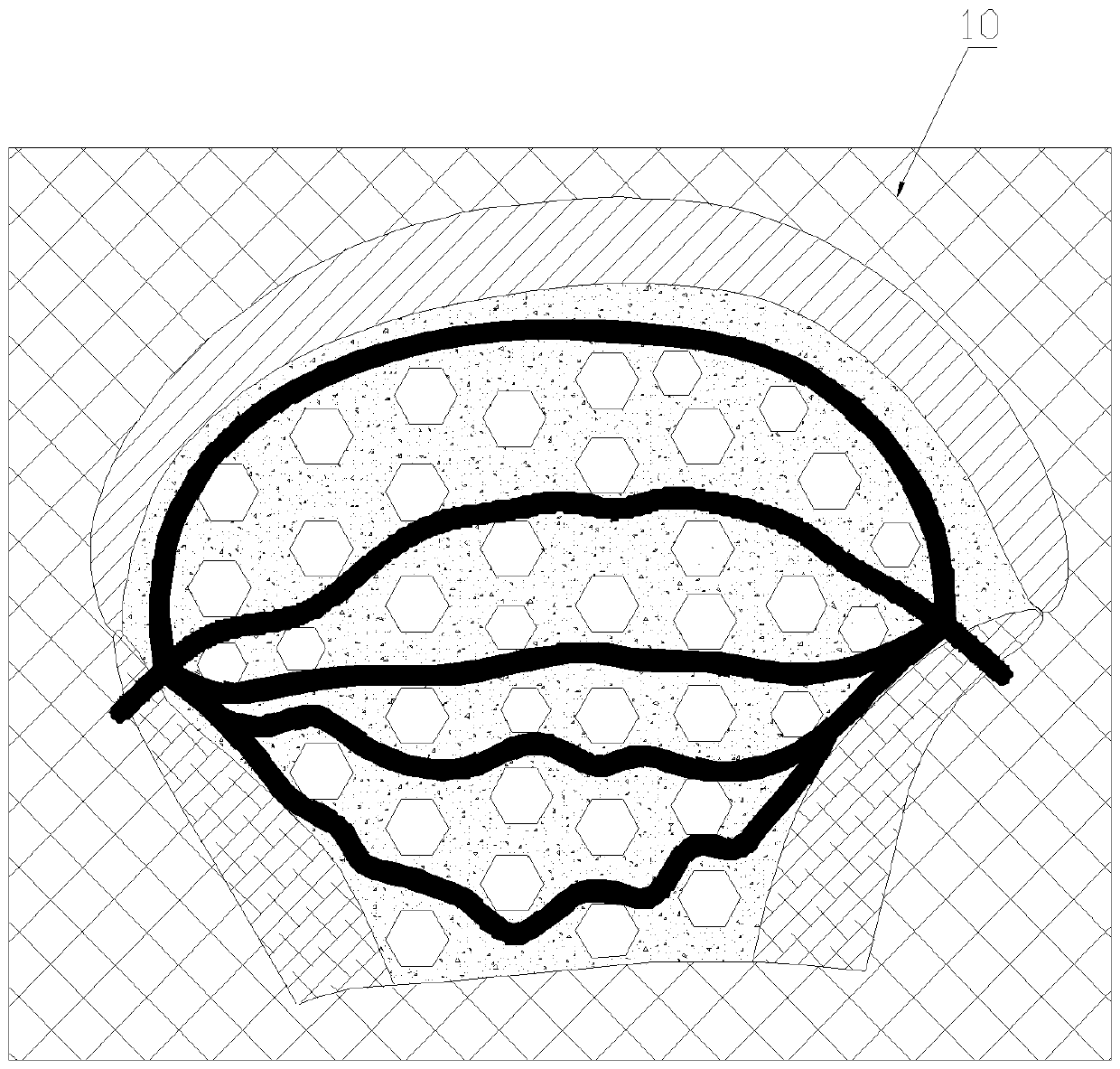

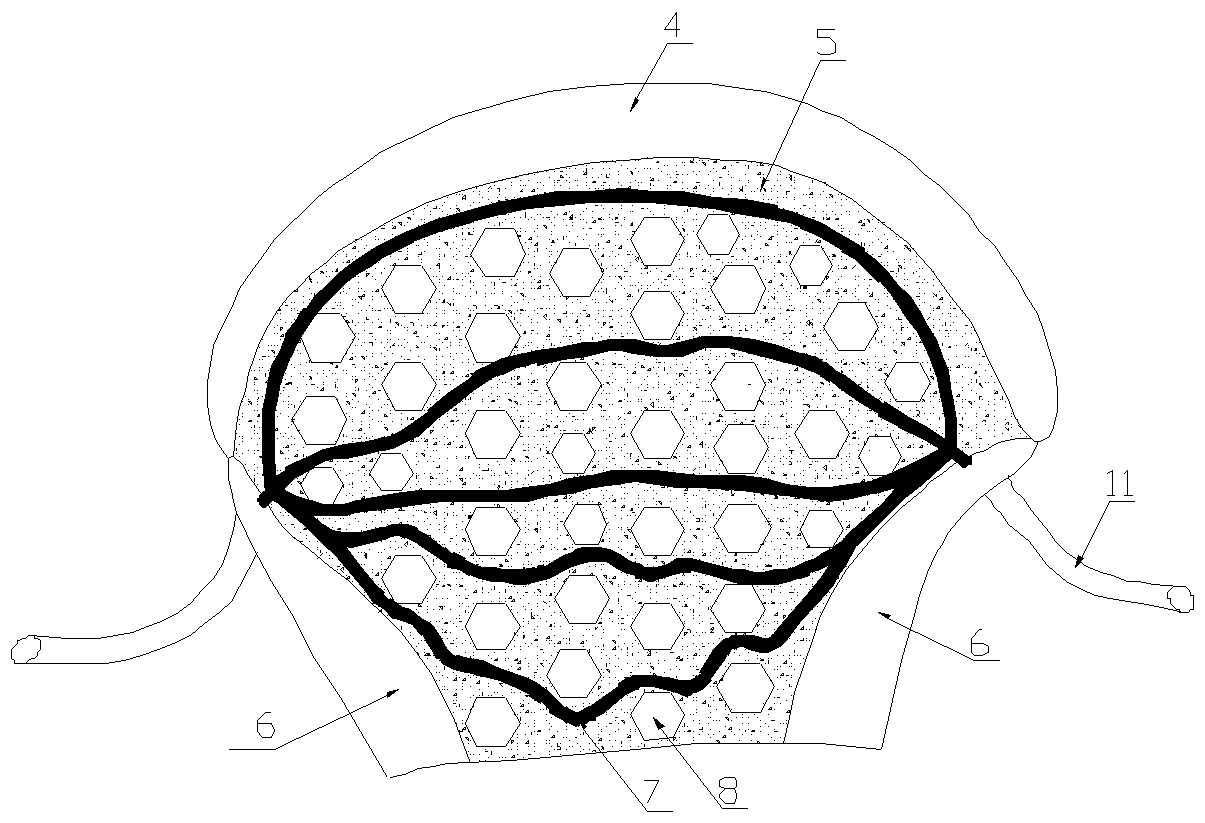

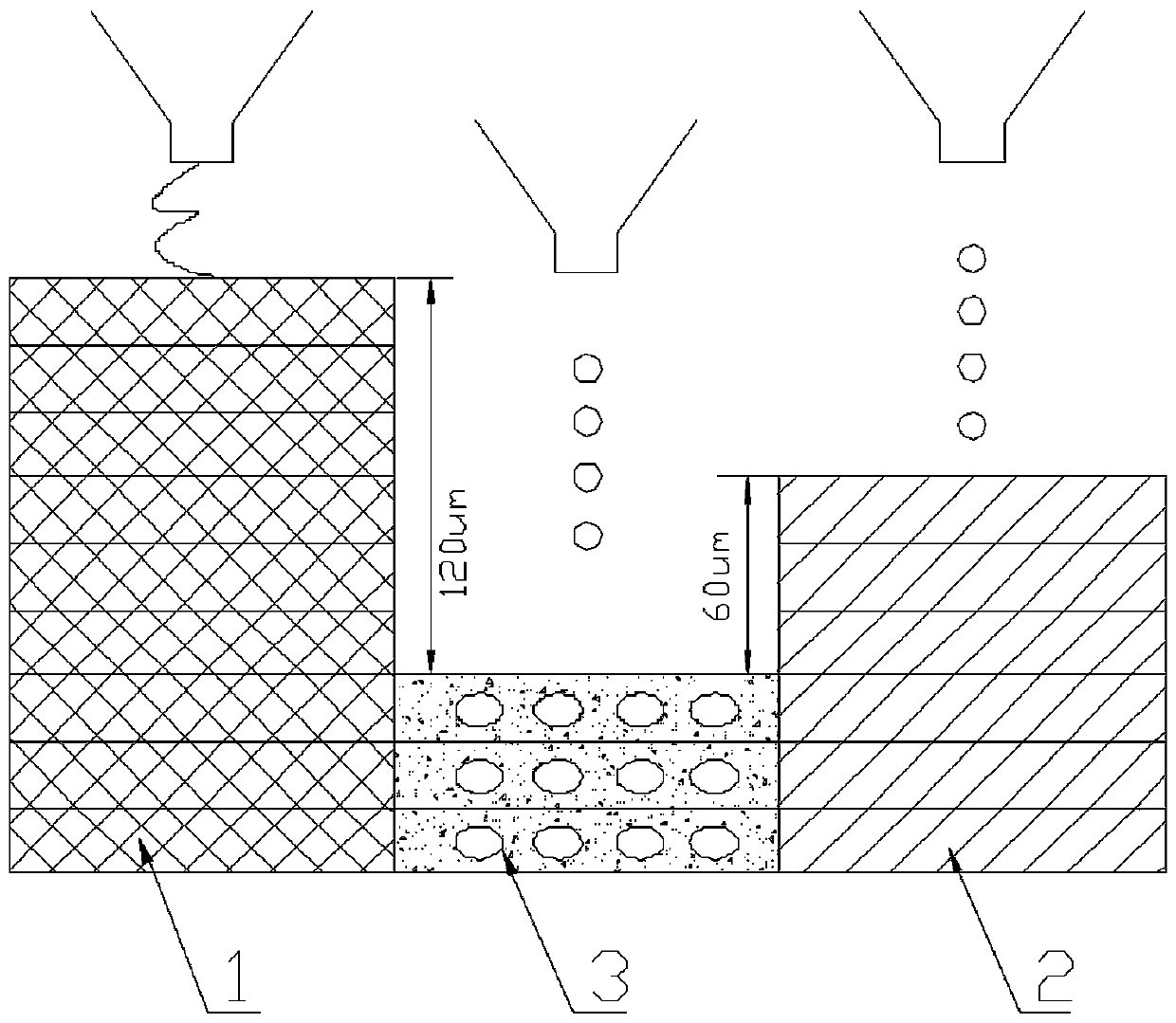

[0042] see figure 1 , figure 2 , Figure 4 , the geometric model includes:

[0043] a. Cartilage area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com