Four-station dual-end process automation production line

An automated production line, four-station technology, used in metal processing, manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as reduced fixture positioning accuracy, reduced machining accuracy of workpieces, and low machine tool processing efficiency. The effect of machining efficiency and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

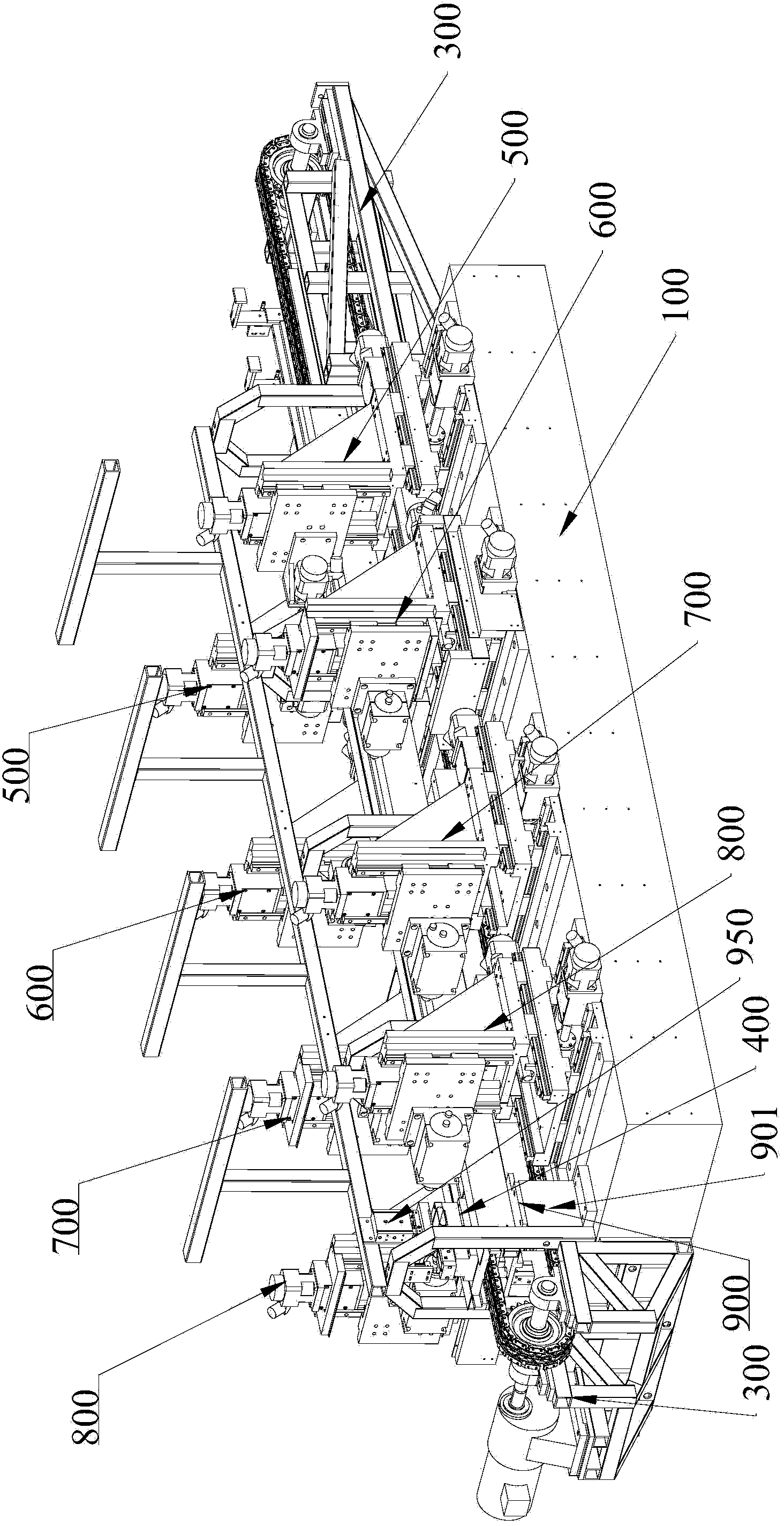

[0075] refer to figure 1 , this embodiment provides a four-station automatic production line for two-end processing, including a bed 100, a tooling circulation device 300, two three-axis linkage rough milling mechanisms 500, two three-axis linkage fine milling mechanisms 600, two three-axis linkage A shaft linkage drilling mechanism 700, two three-axis linkage tapping mechanisms 800 and at least eight clamping devices 400;

[0076] The tooling circulation device 300 is installed on the bed 100;

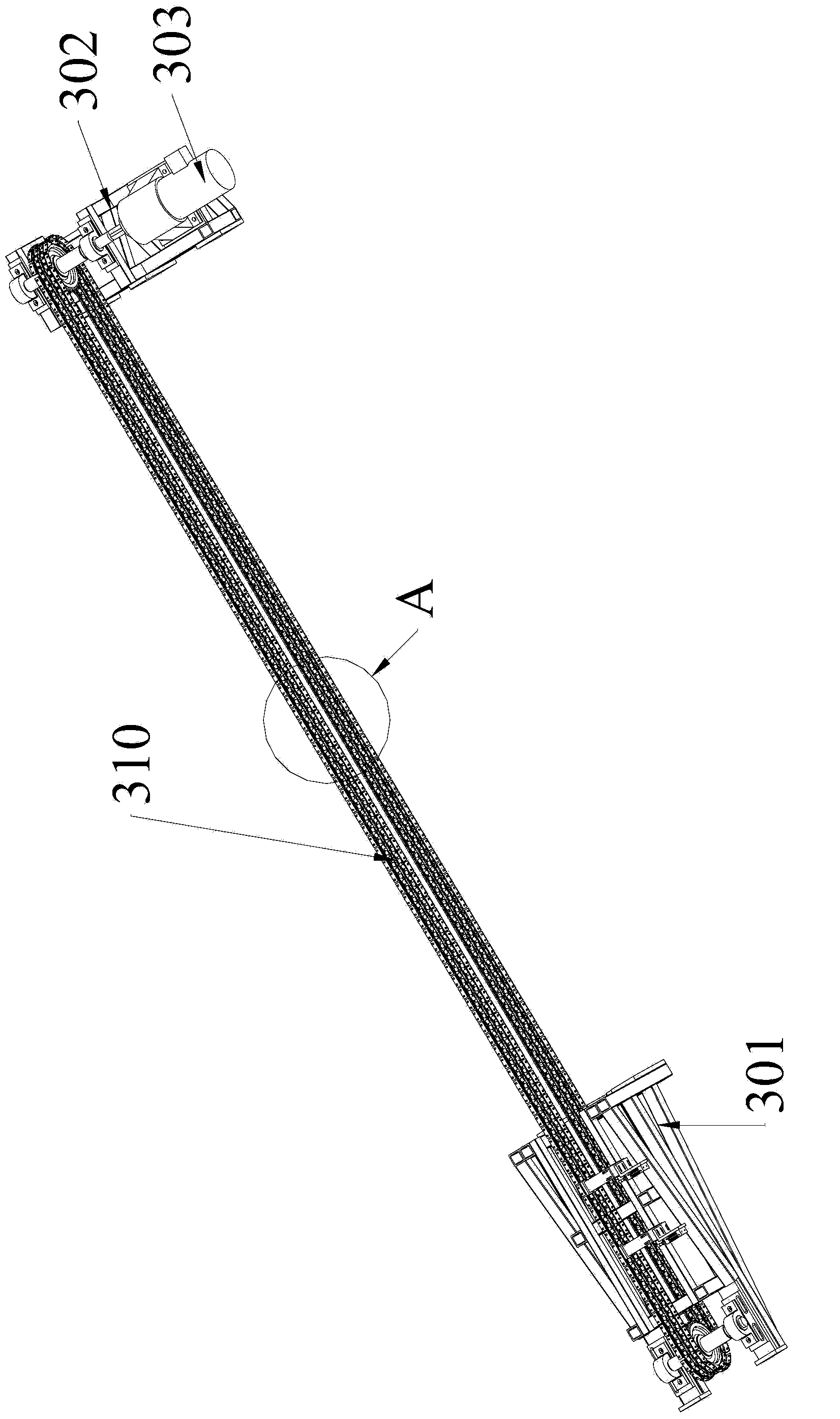

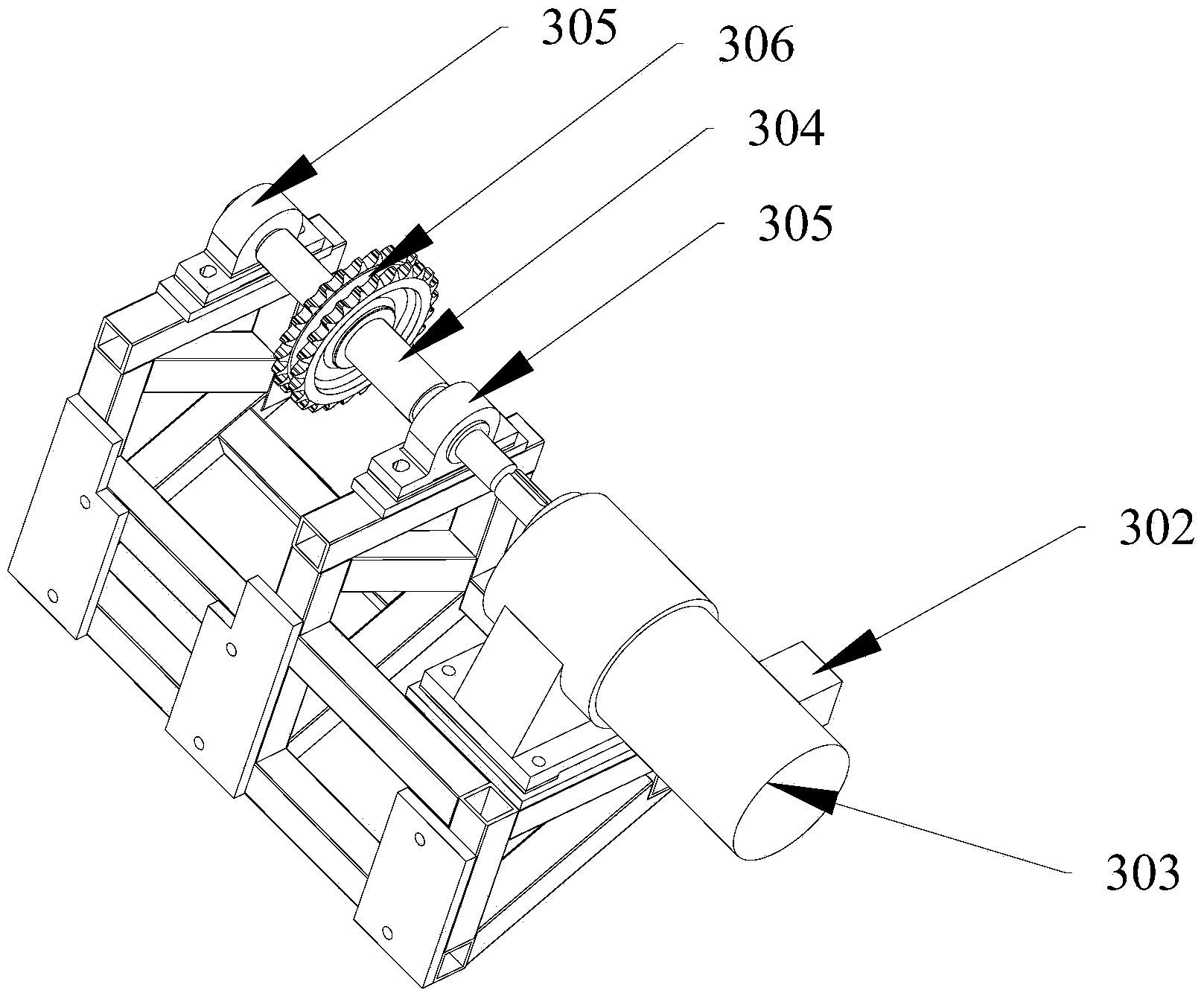

[0077] The at least eight clamp devices 400 are all fixed on the chain 310 of the tooling circulation device 300;

[0078] The two three-axis linkage rough milling mechanisms 500 , the two three-axis linkage fine milling mechanisms 600 , the two three-axis linkage drilling mechanisms 700 and the two three-axis linkage tapping mechanisms 800 are all fixed on the bed 100 , and are respectively located on both sides of the chain 310 of the tooling circulation device 300, and form four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com