Assembly machine of breathable covers of disposable cell culture flasks

一种细胞培养、一次性的技术,应用在组装机、金属加工设备、生物化学设备和方法等方向,能够解决成品良品率不高、延长生产时间、增加产品周转的时间等问题,达到实现自动化生产的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

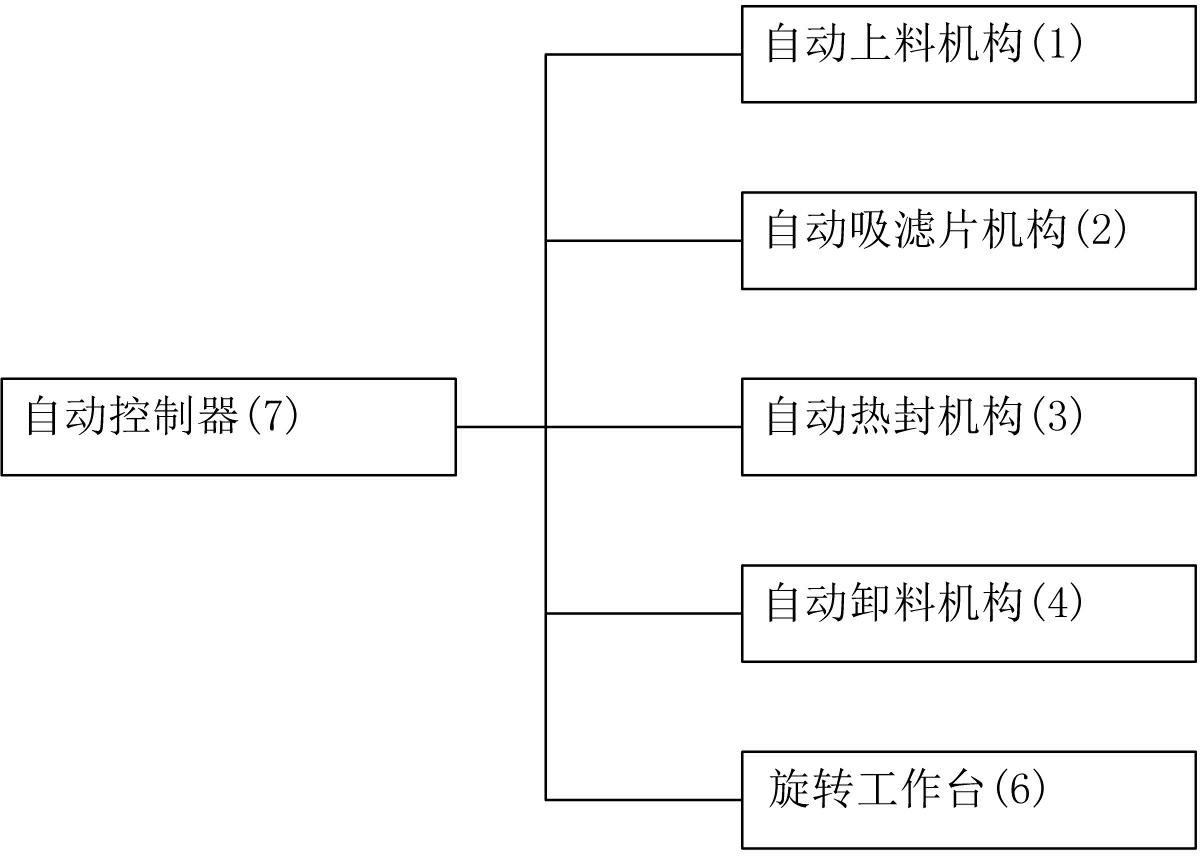

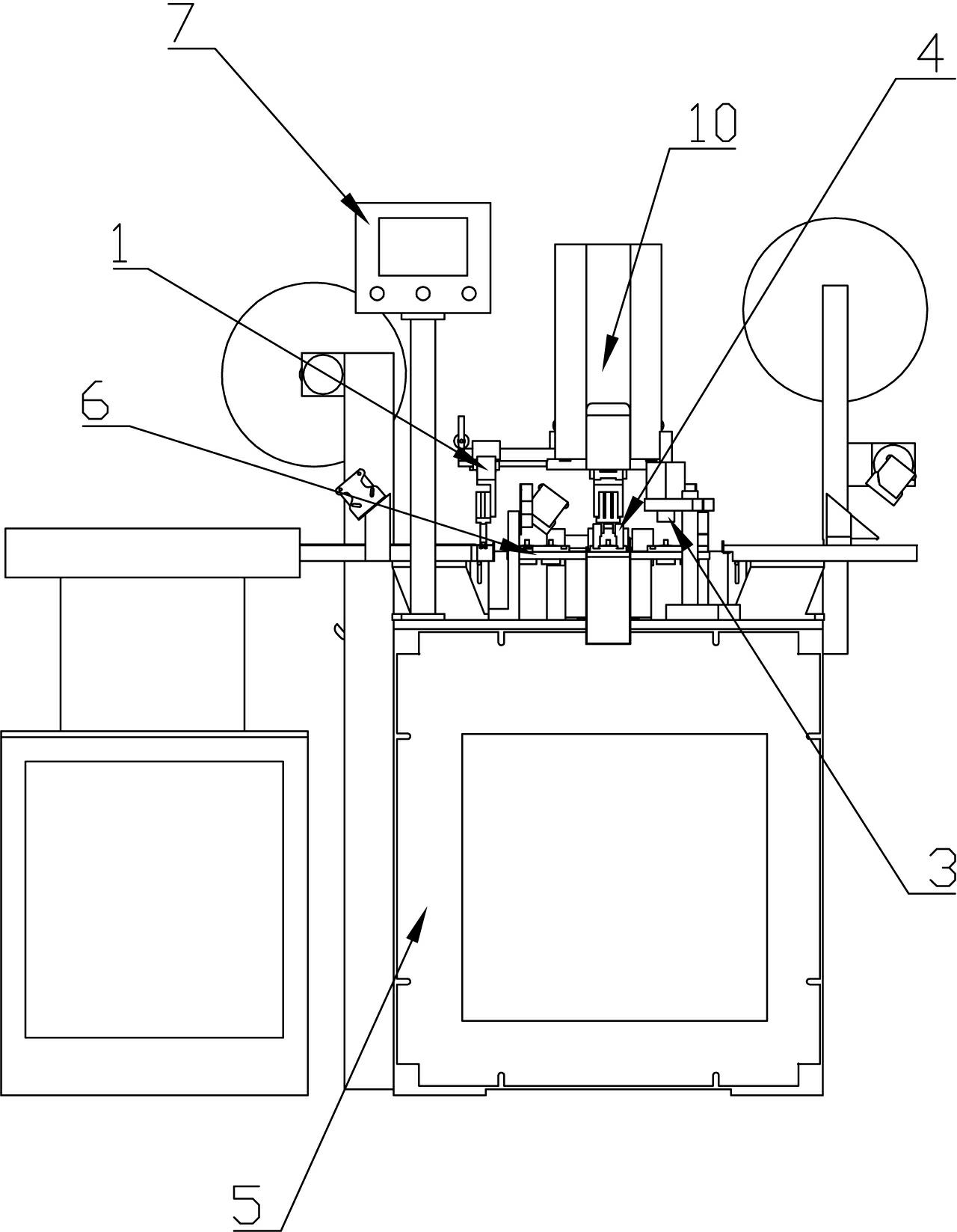

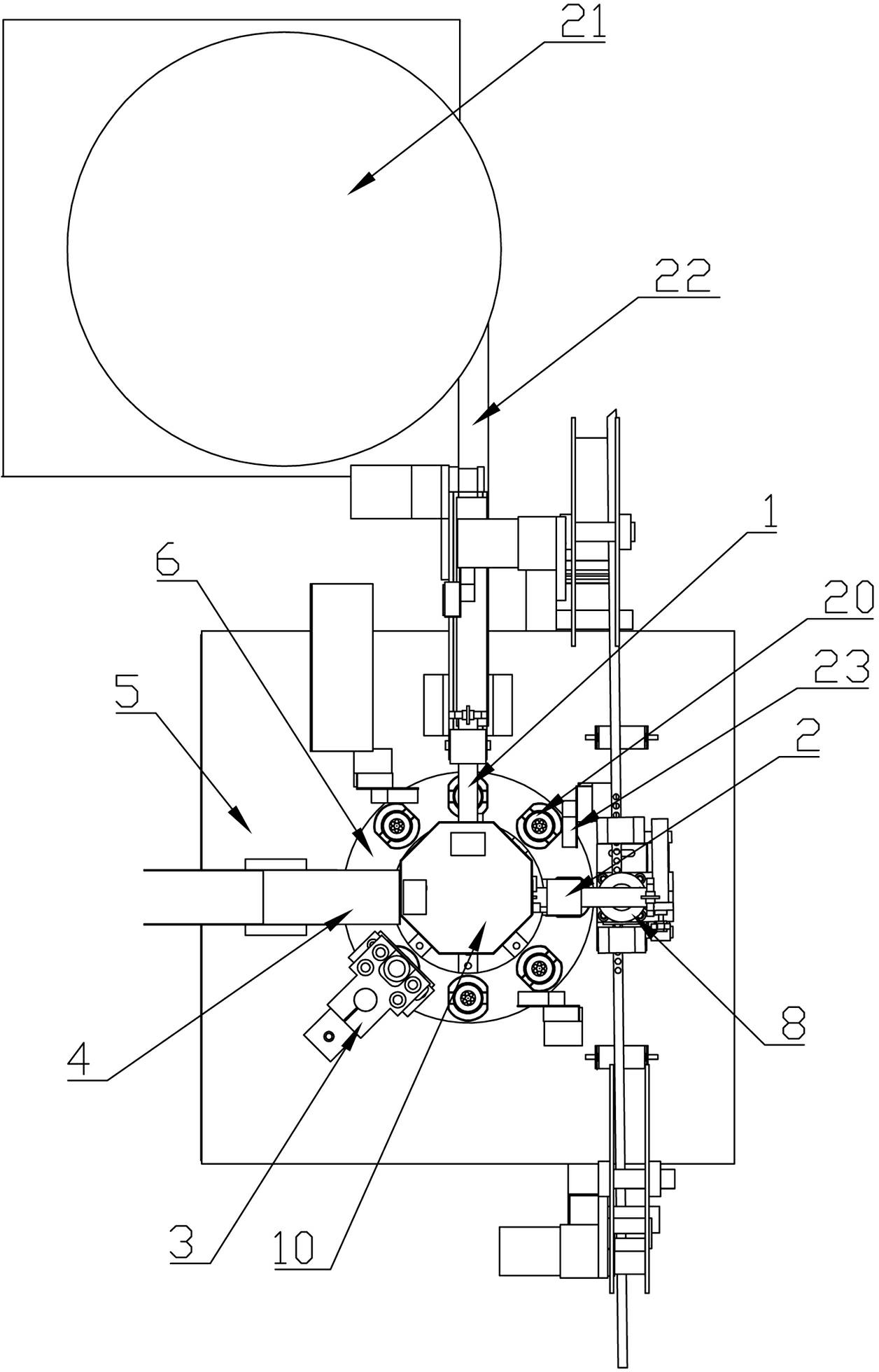

[0024] refer to Figure 1 to Figure 8 , a disposable cell culture flask air cap assembly machine, including a frame 5 and an automatic controller 7 and a rotary table 6 arranged on the frame 5, the rotary table 6 is provided with an automatic feeding mechanism 1, Automatic suction filter mechanism 2, automatic heat sealing mechanism 3, automatic unloading mechanism 4, the automatic controller 7 and the rotary table 6, automatic feeding mechanism 1, automatic suction filter mechanism 2, automatic heat sealing mechanism 3 and The automatic unloading mechanism 4 is electrically connected.

[0025] Through the automatic feeding mechanism 1, the automatic suction filter mechanism 2, the automatic heat sealing mechanism 3 and the automatic unloading mechanism 4, and equipped with the automatic controller 7 and related control circuits, the automatic feeding mechanism is controlled by the automatic controller 7 1. Automatic suction filter mechanism 2, automatic heat sealing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com