Pressing rivet screw automatic feeding device and system

An automatic feeding and screw technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high processing difficulty, low efficiency, uneven production level, etc., achieve automation and mechanization, improve work efficiency, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

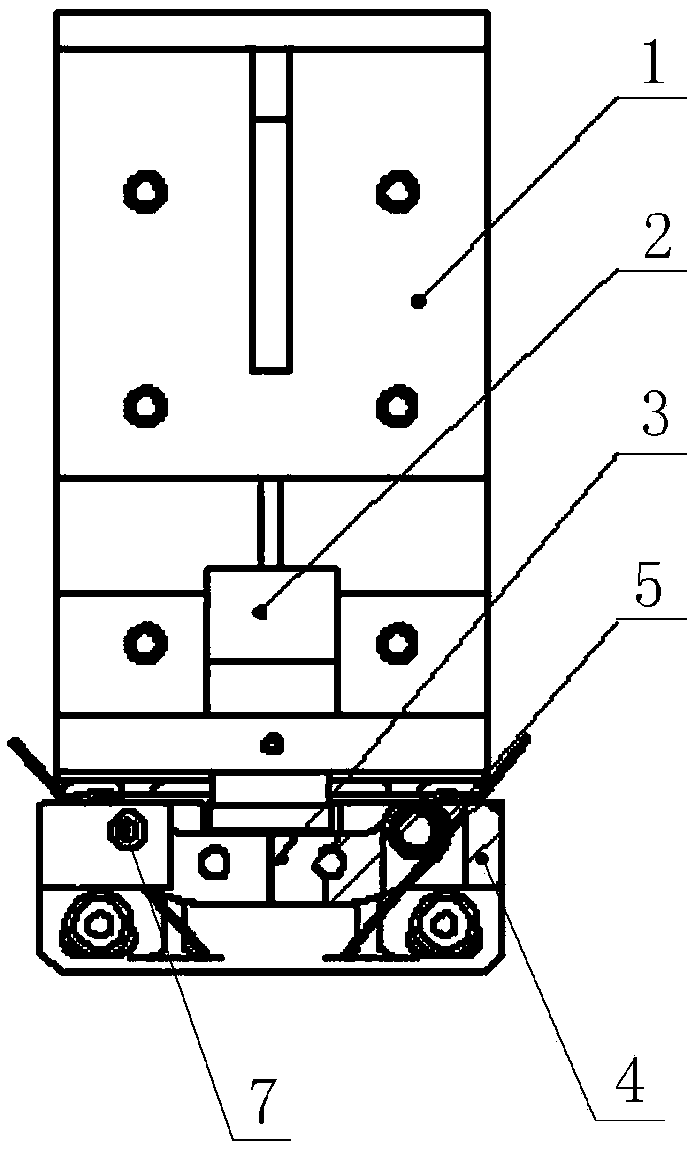

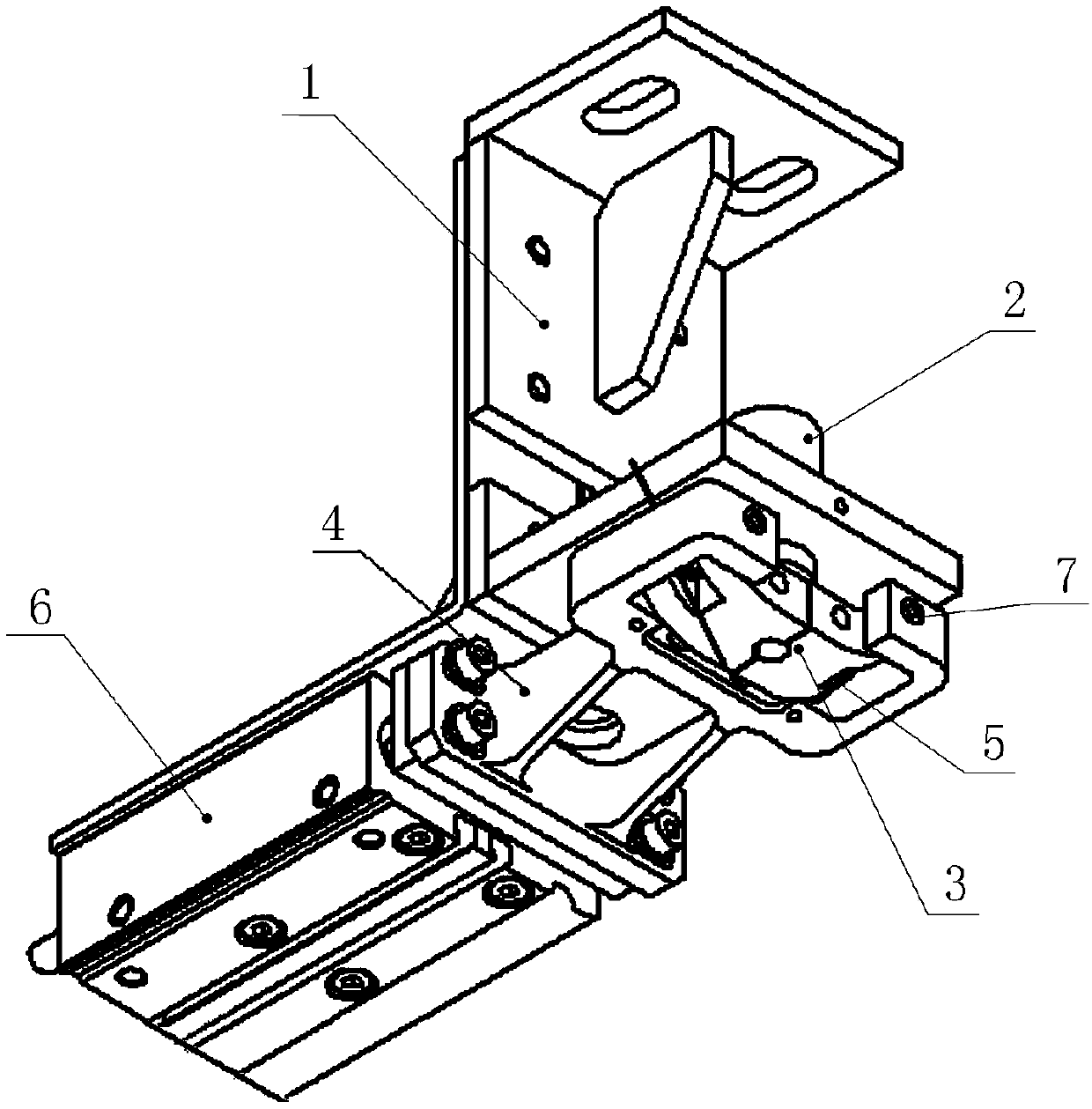

[0024] like Figure 1 ~ Figure 3 As shown, Embodiment 1 discloses an automatic feeding device for pressure riveting screws, which is mainly composed of a mounting bracket 1, a material tube seat 2, a flap 3, a flap bracket 4, a torsion spring 5 and a pushing cylinder 6.

[0025] The material pipe seat 2 is installed on the mounting bracket 1, and the material pipe seat 2 is provided with a material guide hole 2a penetrating from the top surface to the bottom surface; the pushing cylinder 6 is fixedly installed on the bottom of the mounting bracket 1, and the pushing cylinder 6 The piston rod end of the piston rod is forwardly connected with the flap bracket 4, and the telescopic piston rod of the pushing cylinder 6 drives the flap bracket 4 to move forward and backward, and switches between the feeding station and the riveting station.

[0026] The front portion of the flap support 4 is provided with a feed port, and when the flap support 4 is located at the feeding station, t...

Embodiment 2

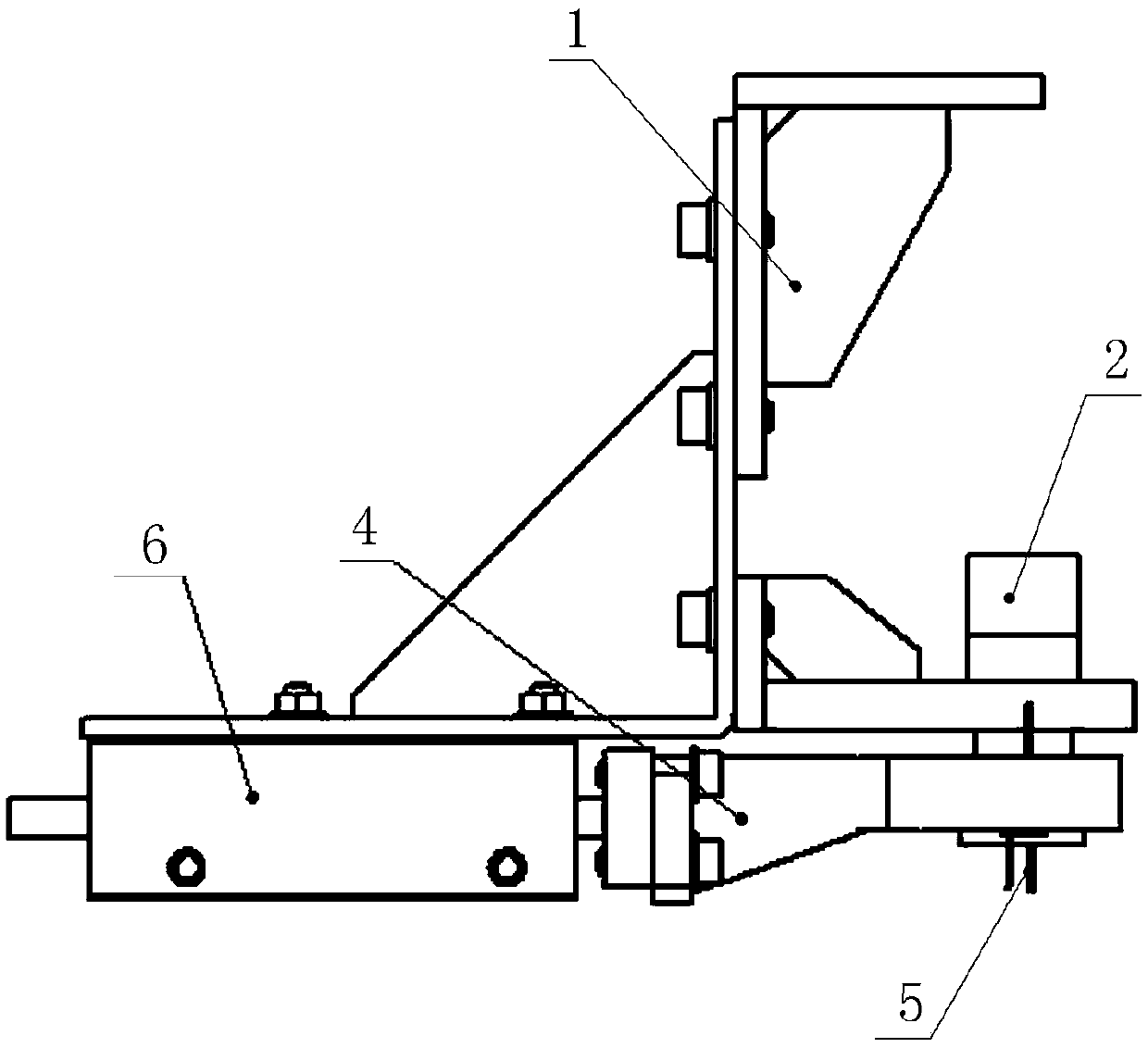

[0030] like Figure 4 As shown, Embodiment 2 discloses an automatic feeding system for pressure riveting screws, which mainly consists of a pressure riveting frame 9, an upper mold 10, a pressure riveting cylinder 11, a lower mold 12, a lower mold base 13, a nail feeding unit, The vibrating plate support 14, the automatic feeding device for riveting screws and the supporting electric control box are composed, wherein the automatic feeding device for riveting screws adopts the automatic feeding device for riveting screws in Embodiment 1.

[0031] like Figure 4 As shown, the riveting frame 9 is provided with a riveting operation position; the upper part of the riveting operation position is provided with an upper die 10, and the upper die 10 is connected with the piston rod end of the riveting booster cylinder 11; The lower part of the pressure riveting operation position is provided with a lower mold 12 corresponding to the upper mold 10, and the lower mold 12 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com