Low-pressure casting automation unit

A low-pressure casting and low-pressure casting machine technology, which is applied in the field of aluminum alloy wheel low-pressure casting automation units, can solve problems such as poor stopping effect, impact on mold life, and impact on product quality, and achieve energy saving of equipment, smooth deceleration and stop, Repeat positioning accuracy and high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

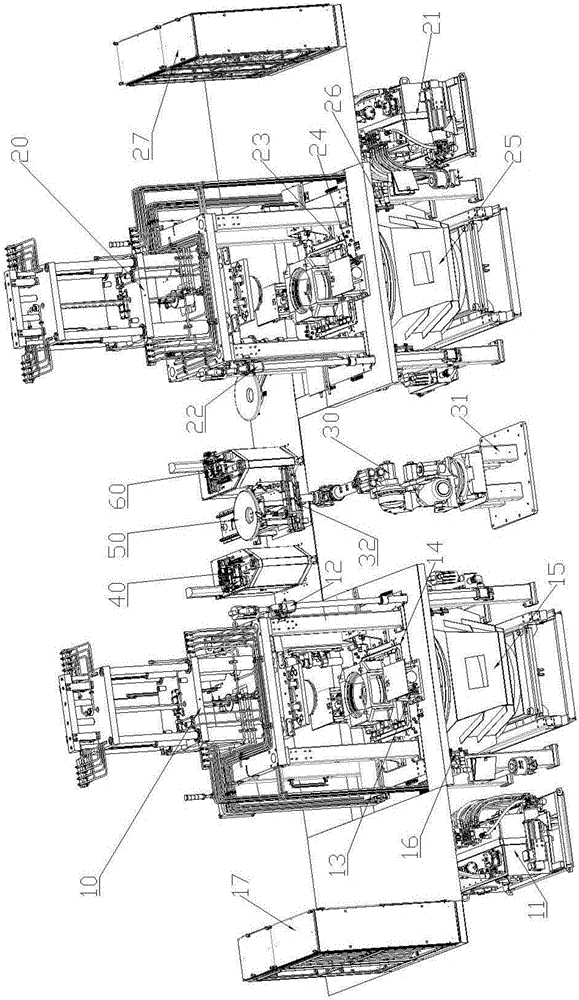

[0034] Such as figure 1 As shown, a kind of low-pressure casting automatic unit equipment of the present invention comprises: a first low-pressure casting machine 10 and a second low-pressure casting machine 20, a six-degree-of-freedom robot 30 is installed on a base 31 between the two low-pressure casting machines, six The degree of freedom robot end mechanism assembly 32 , the first filter mesh supply mechanism 40 and the second filter mesh mechanism 60 , and a material picking mechanism 50 . The six-degree-of-freedom robot 30 can use the R2000iC / 165F casting version robot.

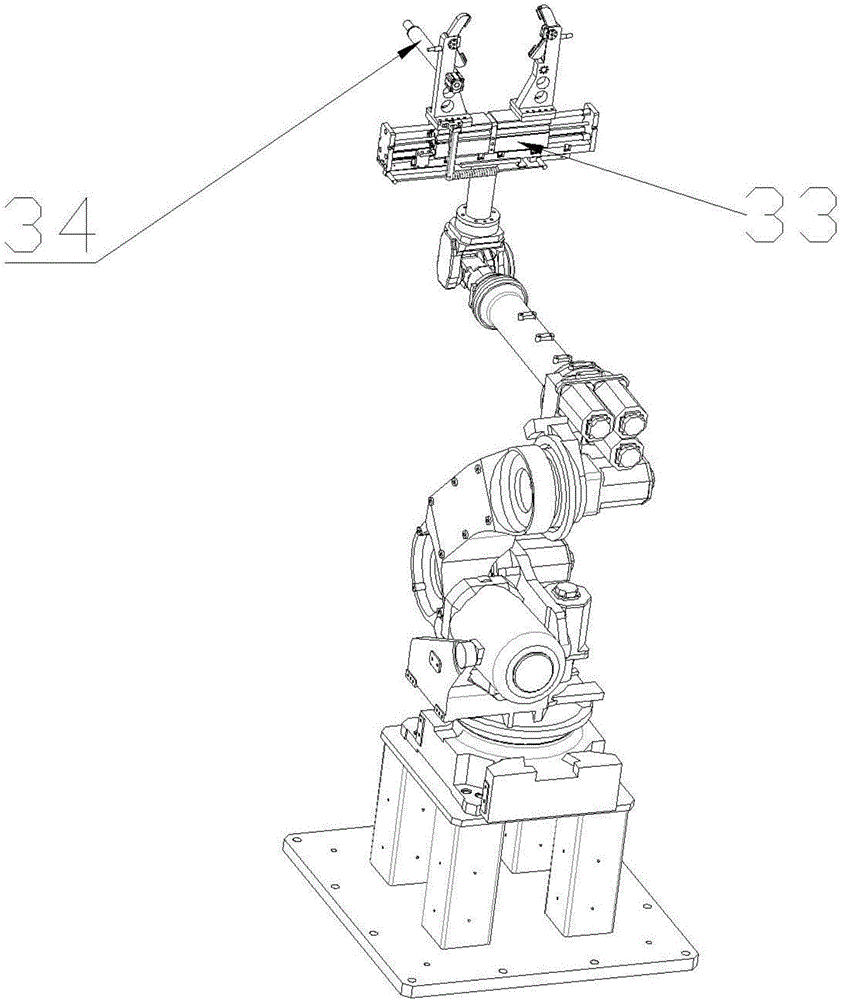

[0035] Such as figure 1 and figure 2 As shown, the six-degree-of-freedom robot 30 is equipped with a terminal mechanism assembly 32 , and the terminal mechanism assembly 32 includes a synchronous clamp 33 and a suction filter mechanism 34 installed on the synchronous clamp 33 .

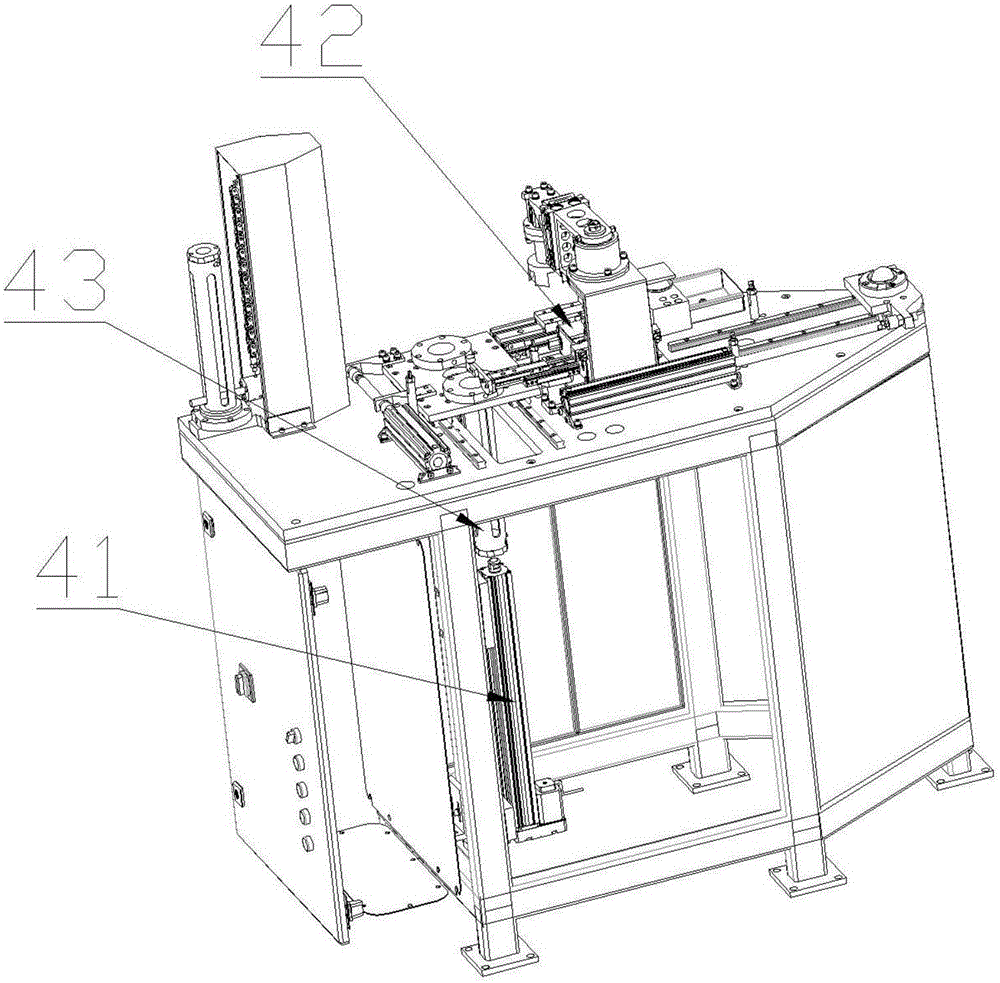

[0036] Two filter mechanisms are installed on the second-floor platform of the automation unit, such as image 3 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com