Clamp and laminating equipment

A fixture and equipment technology, applied in the field of automated production, can solve the problems of pearl cotton deviation and operation duplication, and achieve the effect of improving product quality, reducing personnel input, and solving the problem of not easy to grip and easy to fall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

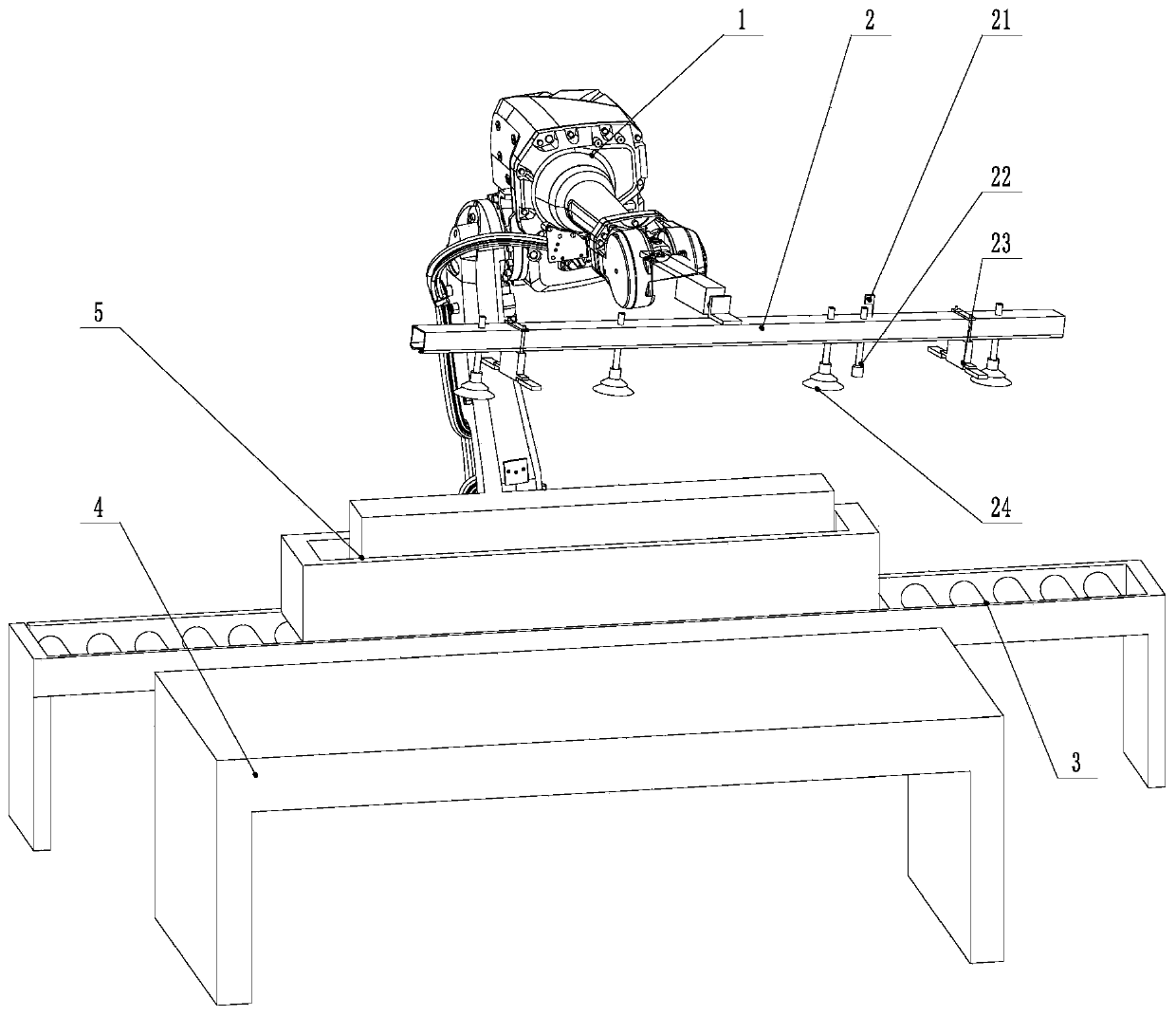

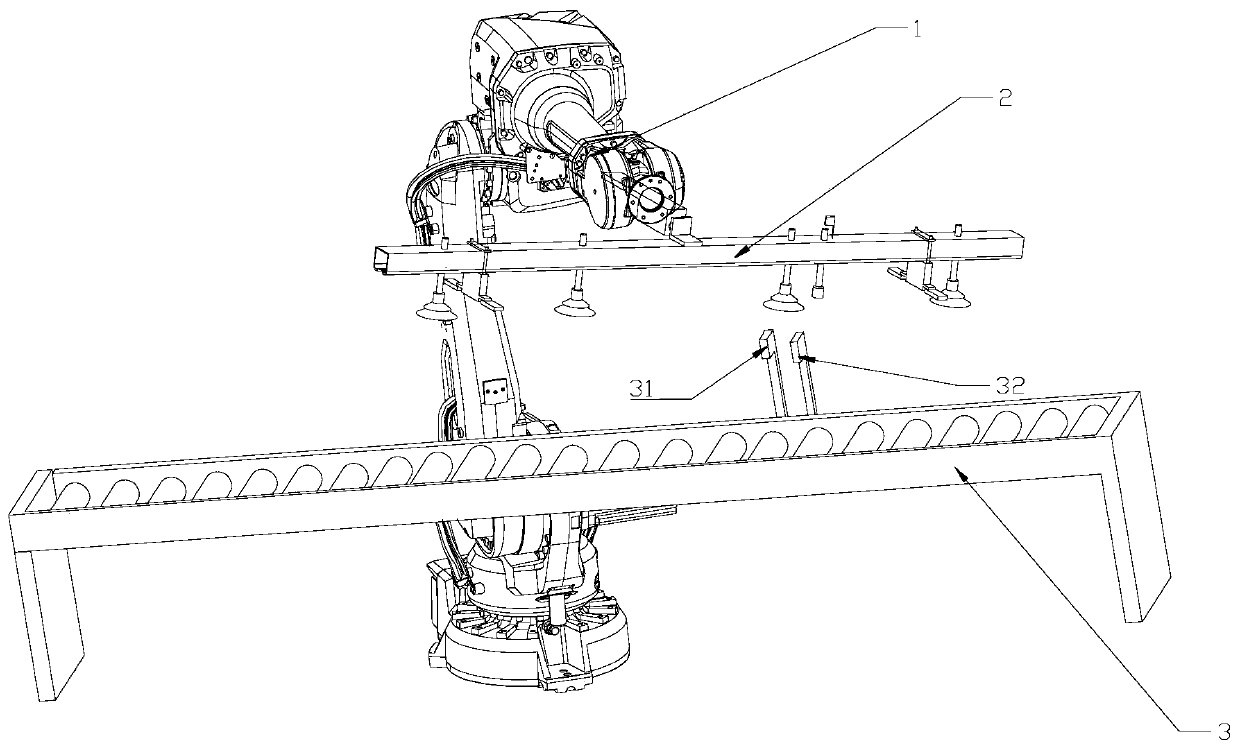

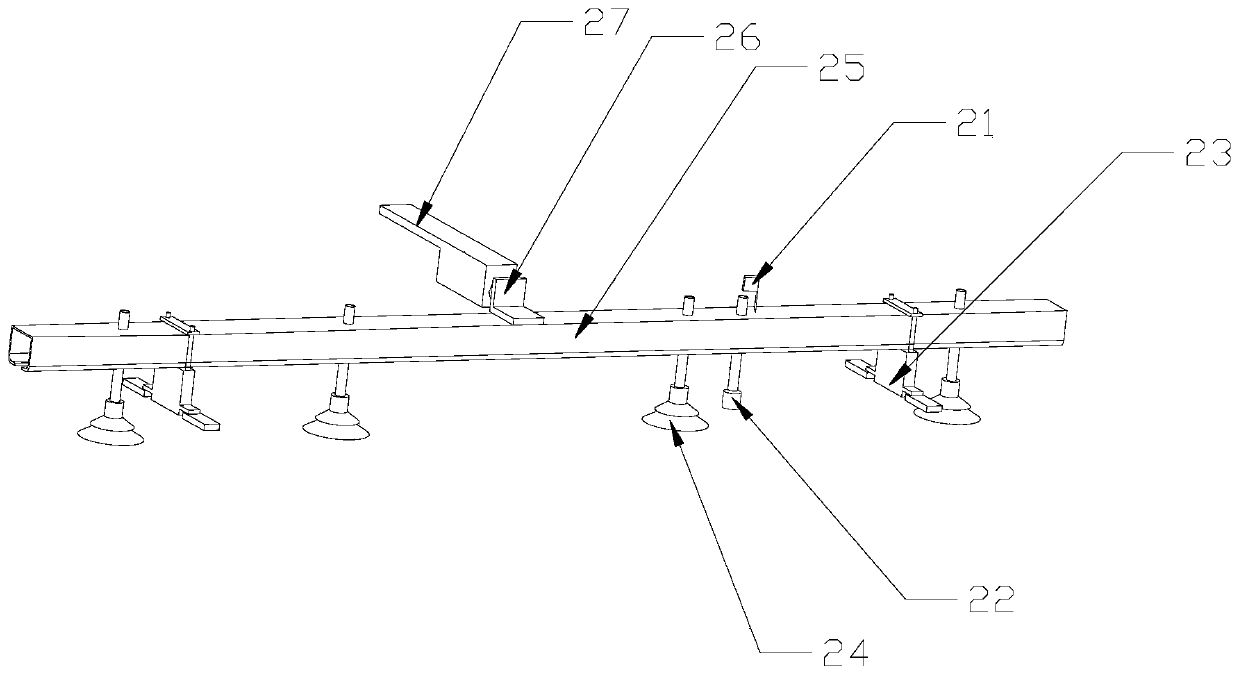

[0019] In order to better understand the purpose, structure and function of the present invention, below in conjunction with appendix Figure 1-3 , a further detailed description of a jig and film covering equipment of the present invention.

[0020] The present invention provides a fixture for wrapping cabinet-type air conditioners. At present, cabinet-type air conditioners need to wrap pearl cotton on the whole machine, so as to prevent dust and reduce bumps and play a buffer role. In the prior art, the process of covering pearl cotton All are manually operated, and the operation is repeated. The present invention also provides an automatic laminating equipment, which replaces manual operation and realizes fully automatic operation of the production line.

[0021] Such as image 3 As shown, the present invention provides a clamp, including a bracket 25, the upper surface of the bracket 25 is provided with a fixed portion 26, the bracket 25 is provided with an induction comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com