Patents

Literature

41results about How to "Improve ash removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

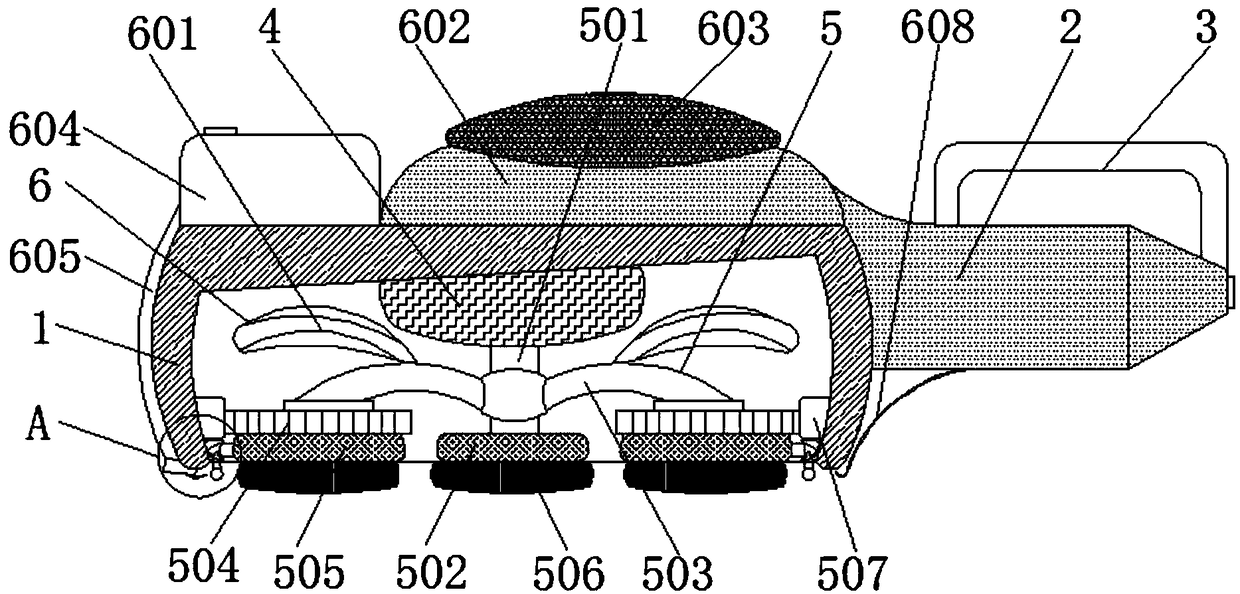

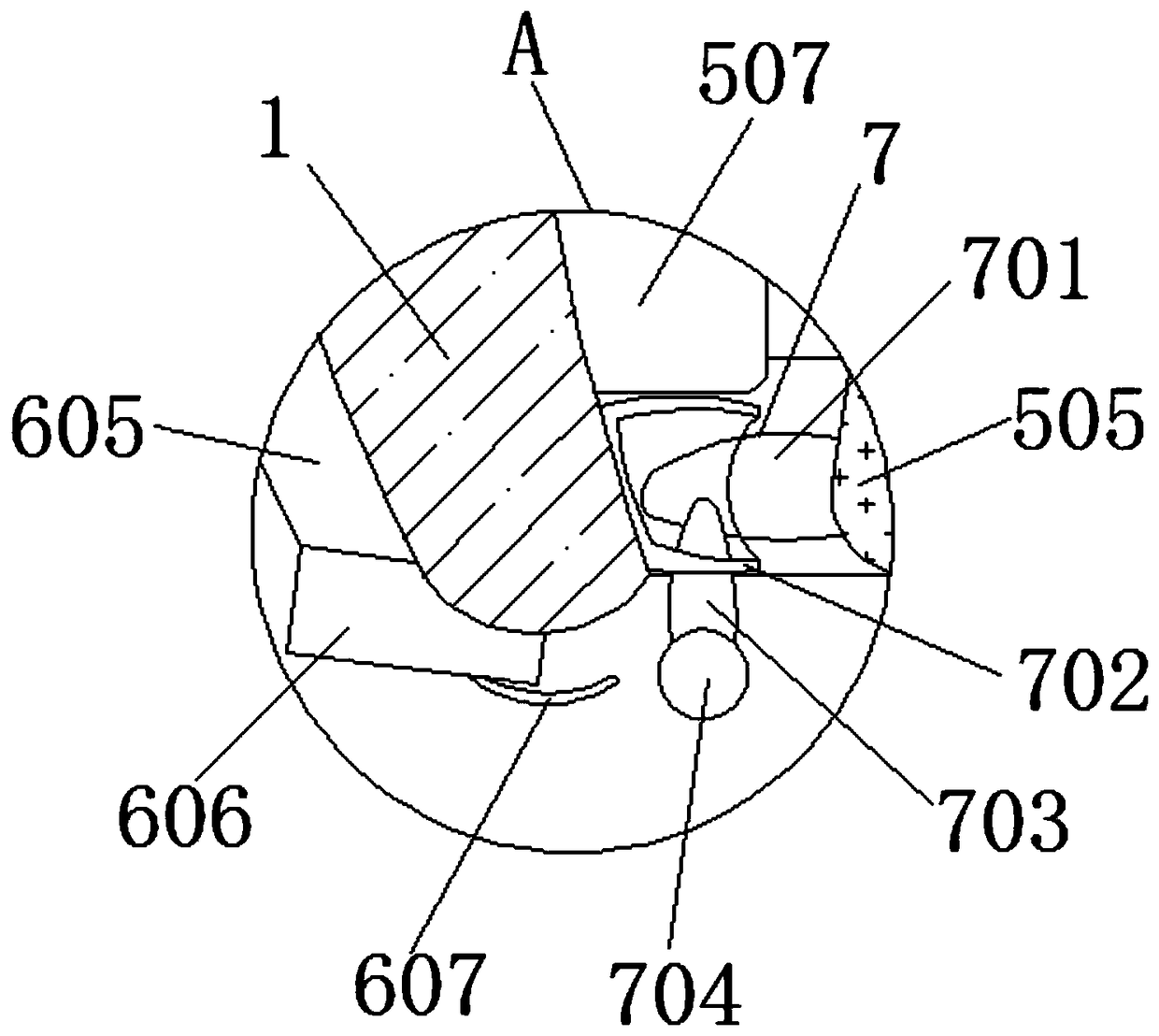

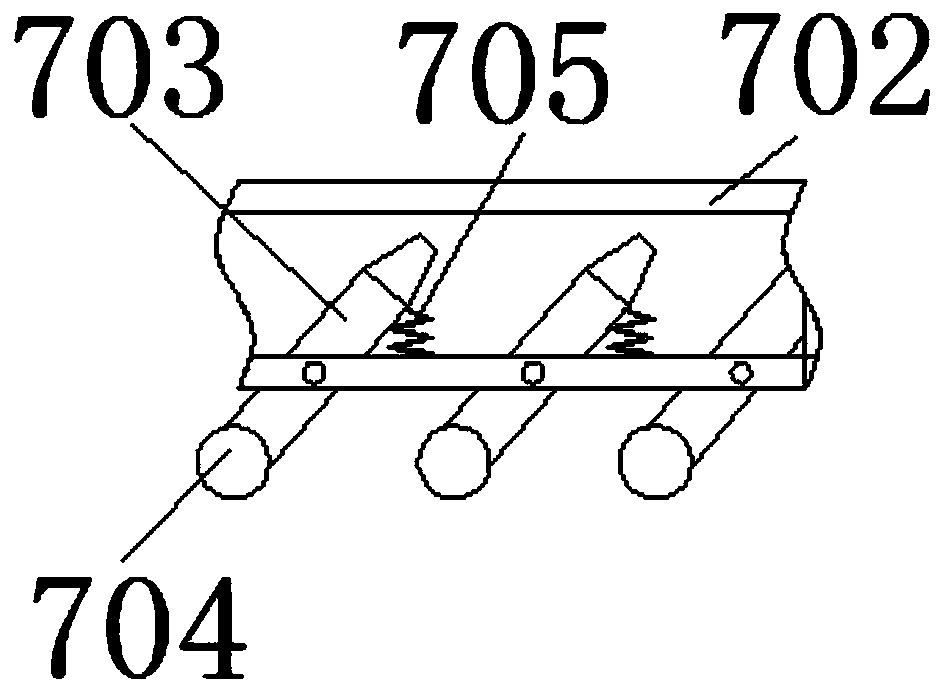

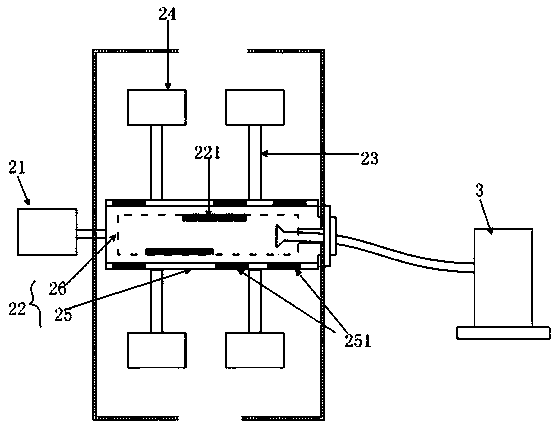

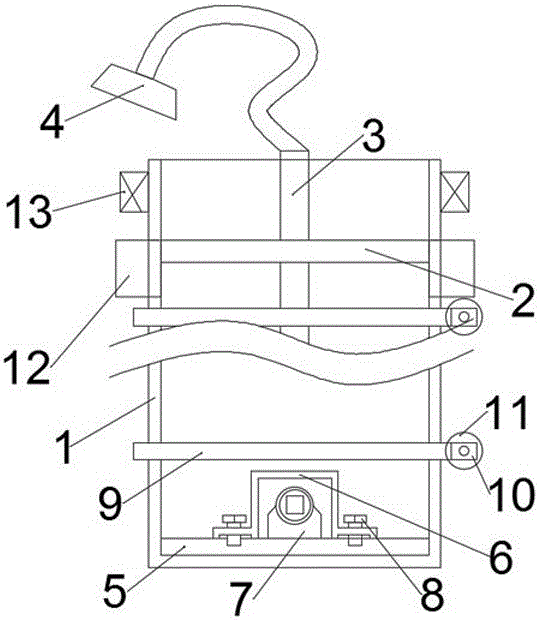

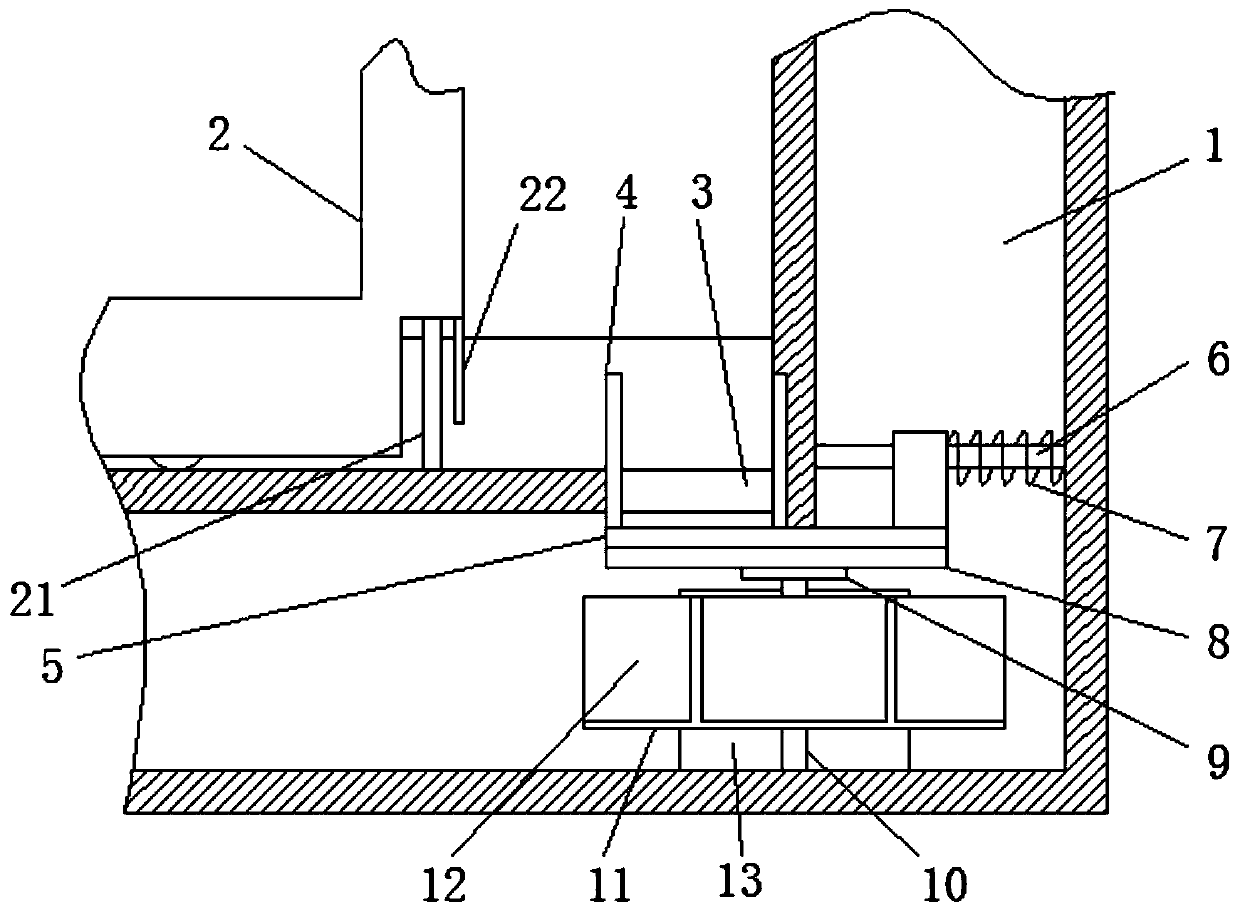

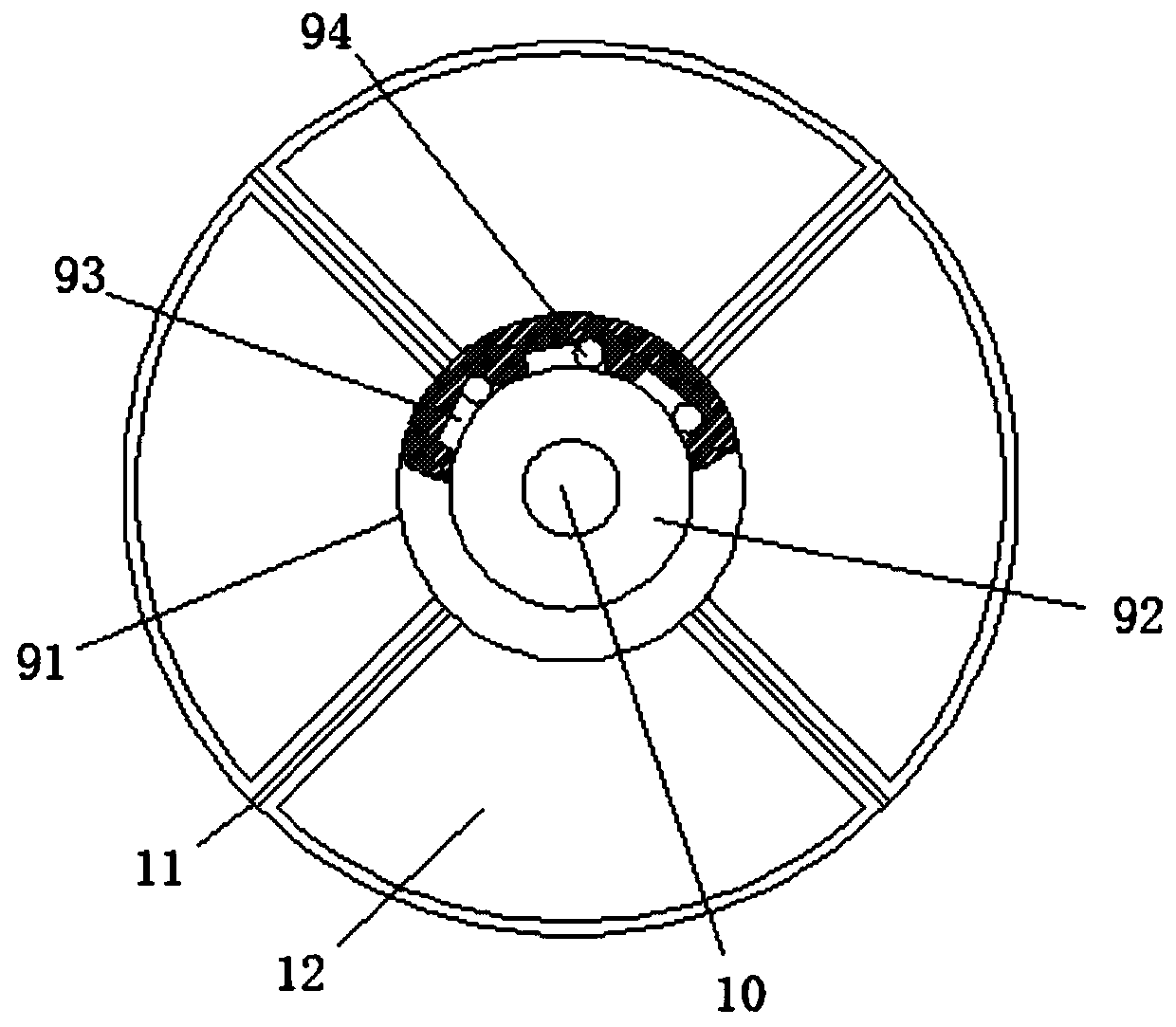

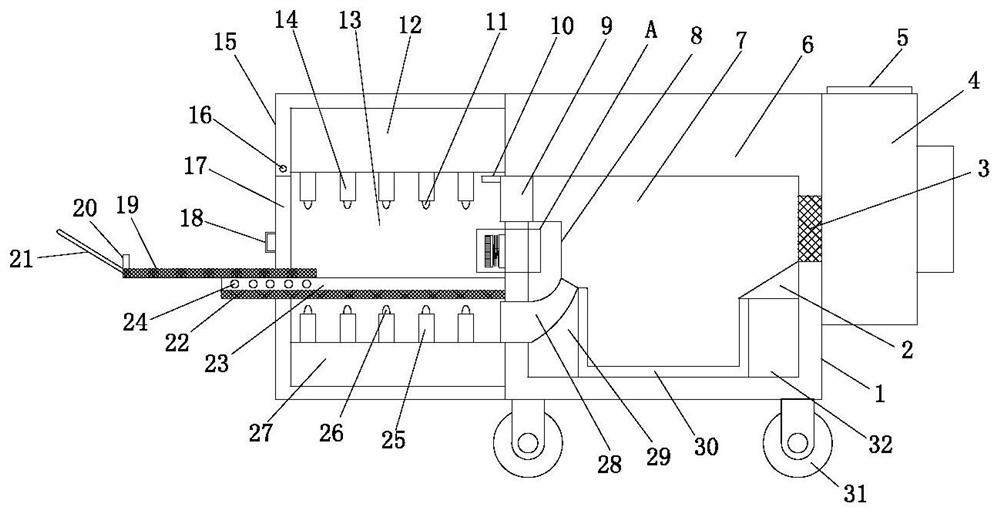

Automatic equipment for cleaning and maintenance of computer hardware

InactiveCN107755359AImprove ash removal efficiencyHigh degree of automationCleaning using toolsCleaning using gasesPistonEngineering

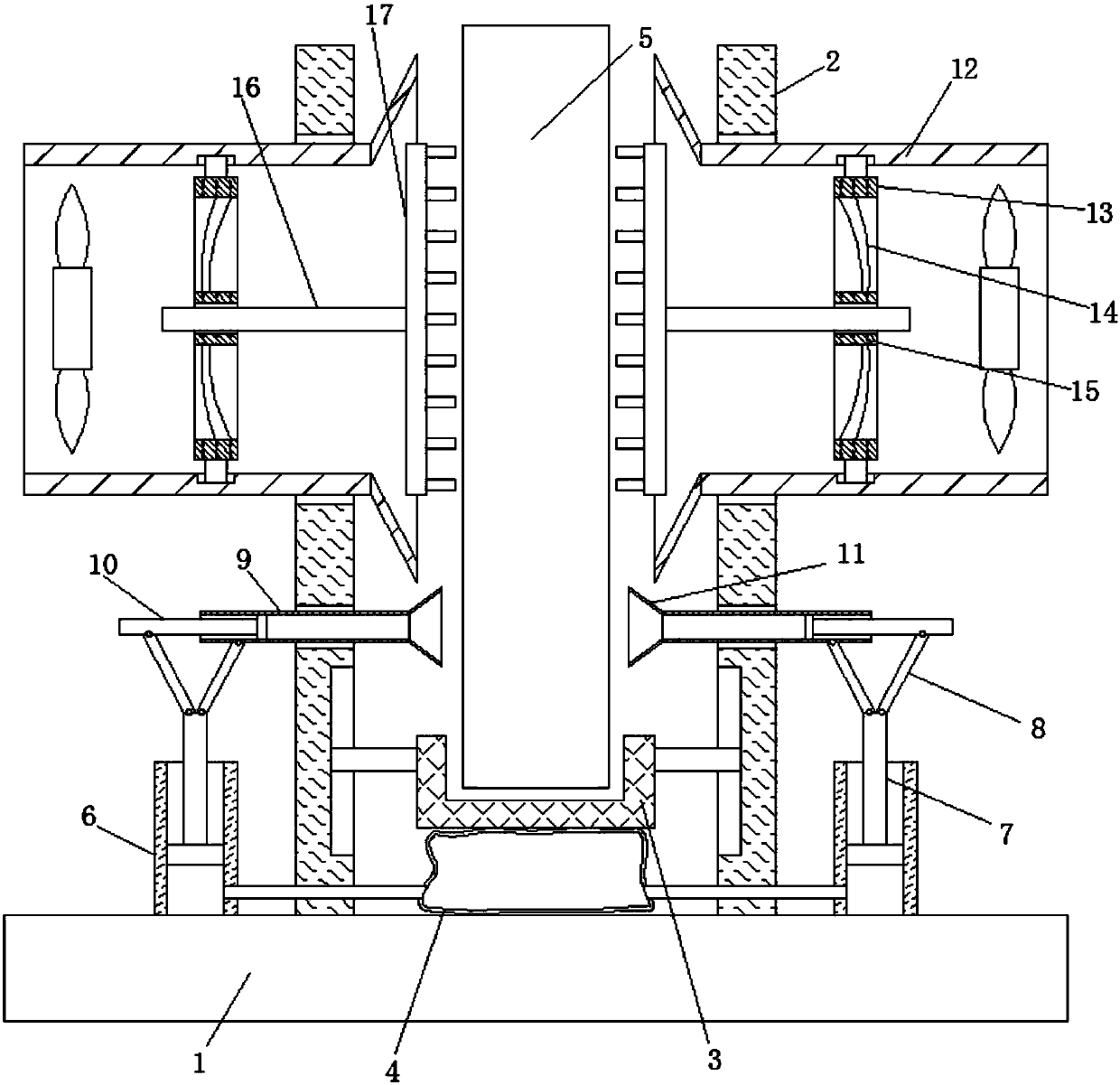

The invention relates to the technical field of computers, in particular to automatic equipment for cleaning and maintenance of computer hardware. The automatic equipment is characterized in that a computer hardware body is clamped at the upper end of a U-shaped clamp plate, two hoses symmetrically penetrate the side wall of an air bag, first T-shaped pistons located above the hoses are in movableinserting connection with the inner walls of cylinders, a sleeve is in movable inserting connection with each vertical plate, opposite ends of the two sleeves are connected with suckers correspondingly, a second T-shaped piston is in movable inserting connection with the inner wall of the end, away from the corresponding sucker, of each sleeve, the other end of each T-shaped piston penetrates thecorresponding sleeve to reach the outside of the corresponding sleeve, the other end of one of straight bars is hinged to the lower end of the corresponding sleeve, dust-proof tubes located above thesleeves are in fixed inserting connection with the vertical plates, and an induced draft fan is mounted in each dust-proof tube. The automatic equipment has the characteristics of simple structure, good dust-proof effect, high degree of automation and the like, and has very high practicability.

Owner:CHENGDU CHUANGNIAN TECH CO LTD

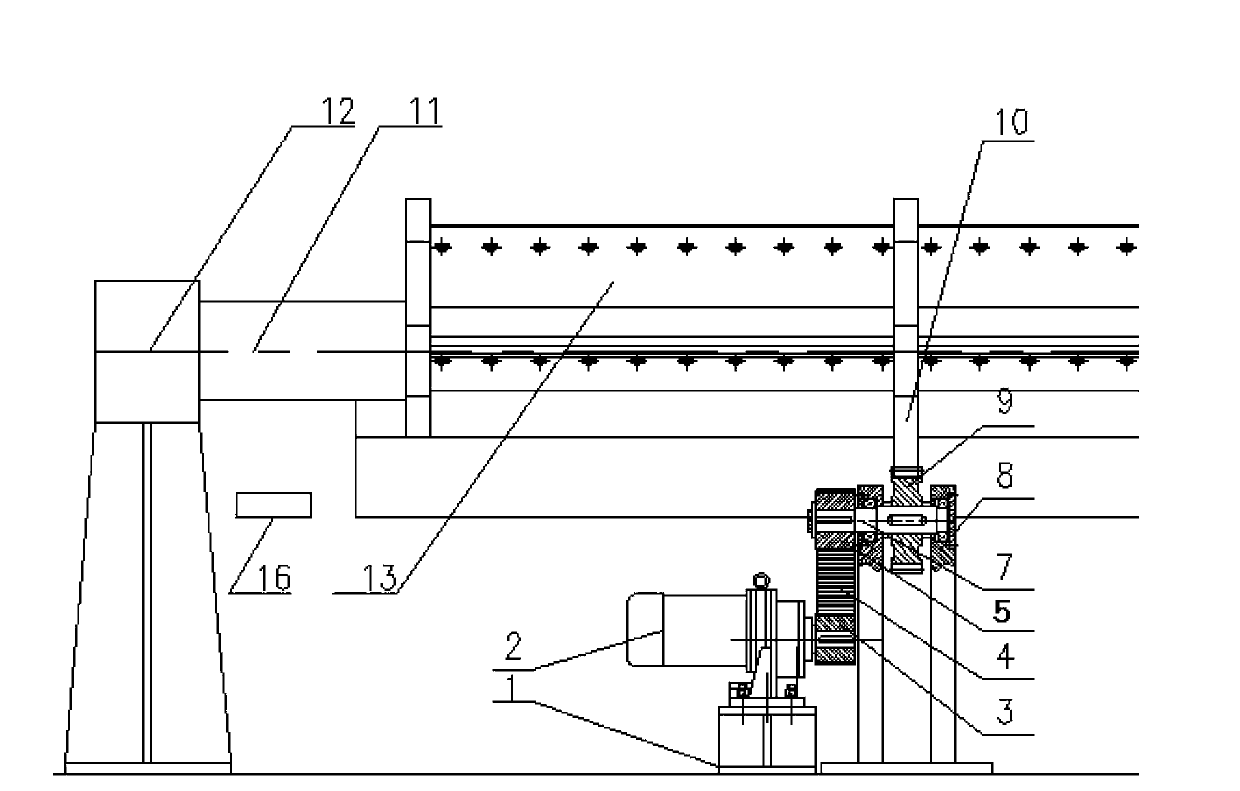

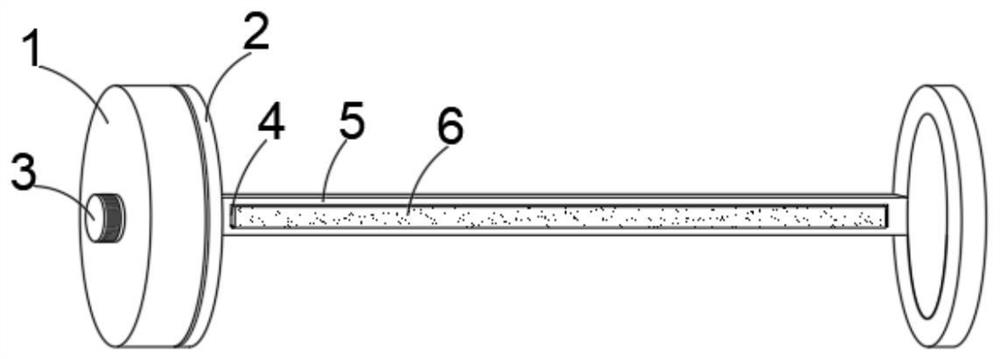

Ash scraping device for hot-dip galvanizing before dip plating

ActiveCN105525245ARealize mechanized operationSmall fluctuationHot-dipping/immersion processesOperating environmentPetroleum engineering

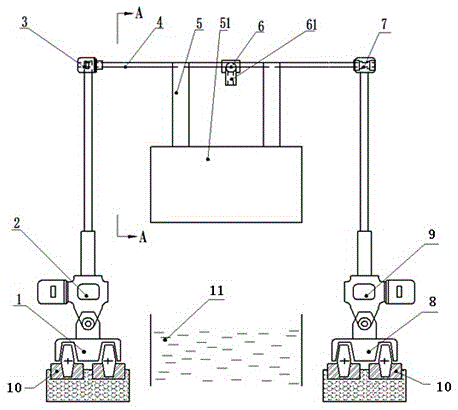

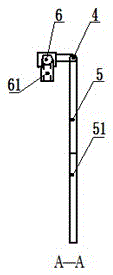

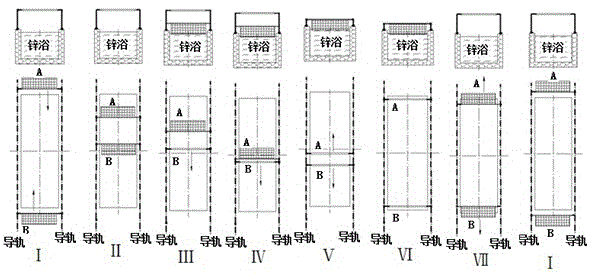

The invention discloses an ash scraping device for hot-dip galvanizing before dip plating, belonging to the technical field of mechanized operation for batch of hot-dip galvanizing. The device comprises electric trolleys, electric push rods, a gear motor, a rotation shaft and a bearing support, wherein guide rails are arranged on the two sides of a zinc pot, the electric trolley I and the electric trolley II are respectively arranged on the guide rails, and the lower ends of the electric push rod I and the electric push rod II are respectively to the electric trolley I and the electric trolley II; the gear motor is fixed at the upper end of the electric push rod I, and the output shaft of the gear motor is connected with one end of the rotation shaft; the other end of the rotation shaft is fixed on the bearing support, and the bearing support is fixed on the telescopic rod of the electric push rod II; a scraping plate and an infrared detector are arranged under the rotation shaft. The ash scraping devices are used in pairs in the ash scraping operation and are respectively distributed at the two ends of the zinc pot on the length direction. The ash scraping device mechanically scrapes ash on a zinc bath surface before dip plating in the process of batch of hot-dip galvanizing during working, replaces traditional manual ash scraping, and improves the operating environment.

Owner:KUNMING UNIV OF SCI & TECH +1

Loudspeaker box dust screen cleaning device capable of combining inertial dust collection with airflow lotion dust collection

ActiveCN108970281AImprove cleaning qualityEasy to wipeDispersed particle filtrationTransportation and packagingDrive motorEngineering

The invention provides a loudspeaker box dust screen cleaning device capable of combining inertial dust collection with airflow lotion dust collection, and relates to the field of loudspeaker box cleaning equipment. The loudspeaker box dust screen cleaning device capable of combining inertial dust collection with airflow lotion dust collection comprises a supporting fixed housing, wherein the sidewall of the supporting fixed housing is spliced with a holding internal hollow fixing barrel; the side wall of the holding internal hollow fixing barrel is spliced with a lateral grip; the top of theinner wall of the supporting fixed housing is spliced with a dust-proof moisture-proof protecting case; the top of the supporting fixed housing is provided with a floating dust cleaning and removal mechanism. According to the loudspeaker box dust screen cleaning device capable of combining inertial dust collection with airflow lotion dust collection, one end of a rotary sliding rod is controlledby a driving motor to slide in a concave sliding ring to enable the rotary sliding rod to incline to one side of a jacking spring; after sliding, an overturning linkage rod is jacked under the elasticfunction of the jacking spring to drive a round knocking ball on the end part of the overturning linkage rod to knock the loudspeaker box dust screen, dust is separated from the dust screen due to the influence of inertia, and the dust removal efficiency of the loudspeaker box dust screen is effectively improved.

Owner:临沭县济才人力资源服务有限公司

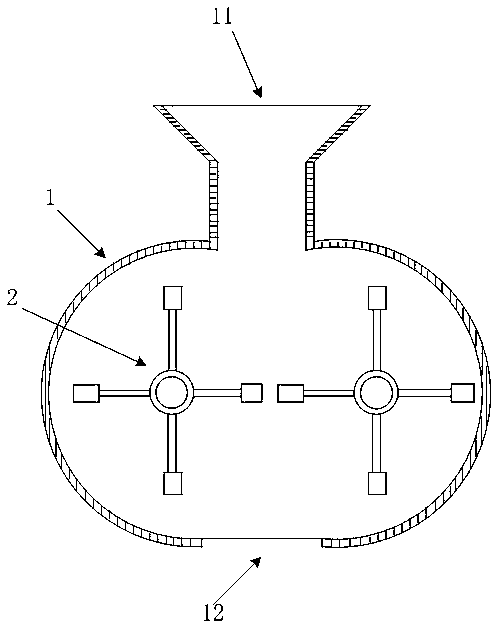

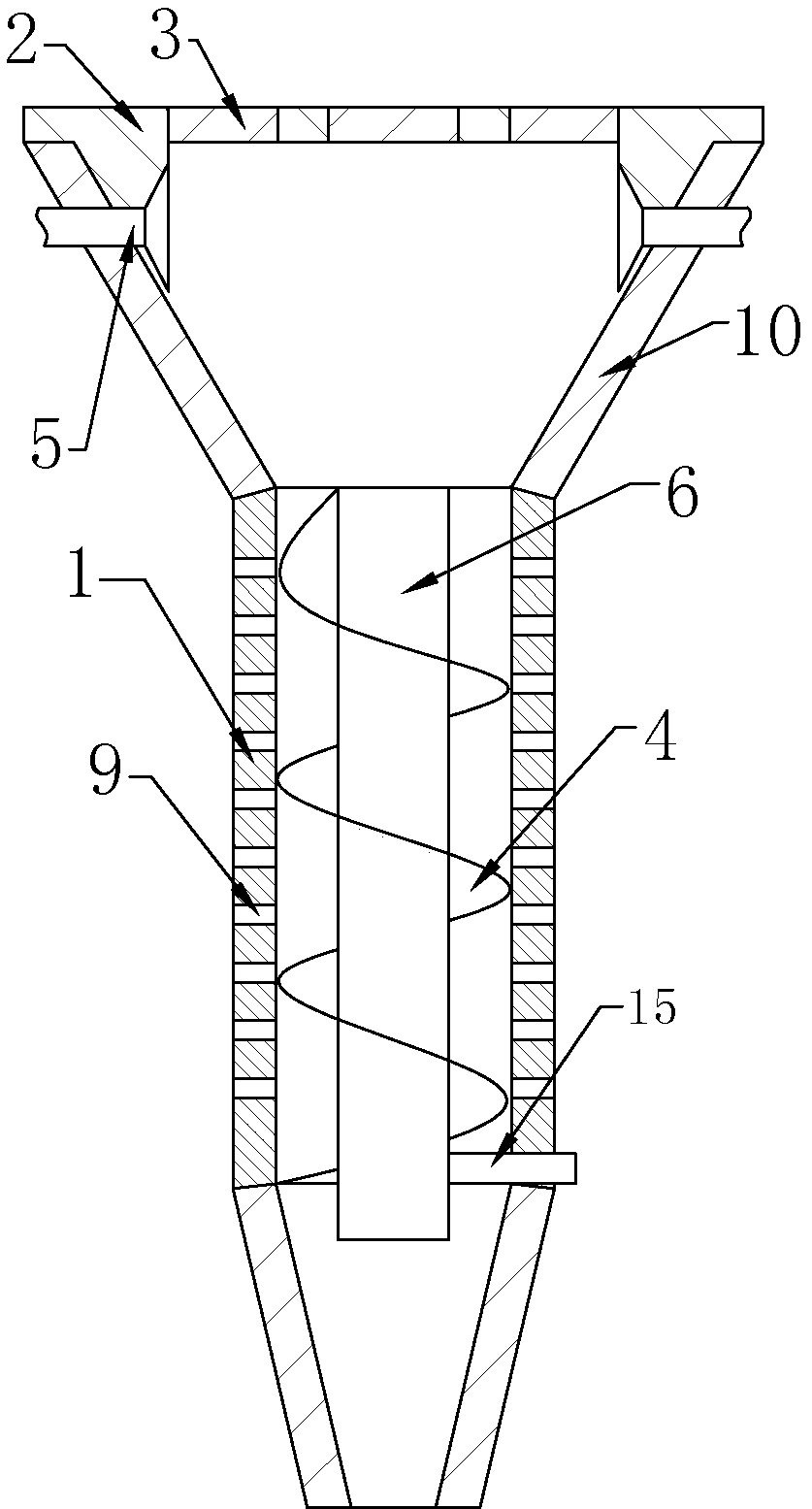

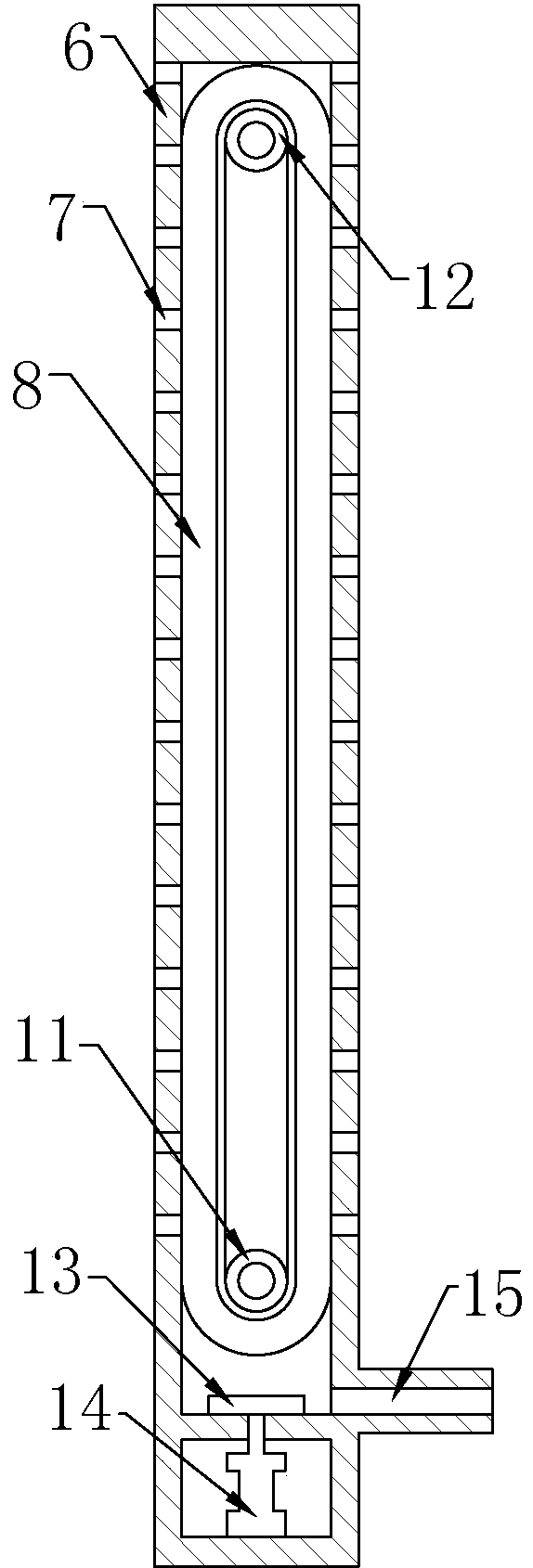

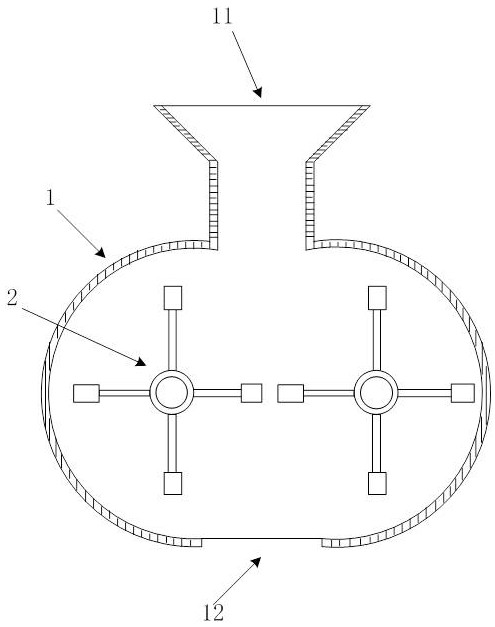

Dust removal device used for rice fine processing and usage method

ActiveCN109692722AImprove separation efficiencyReduce process stepsGrain huskingSievingIron removalFood safety

The invention discloses a dust removal device used for rice fine processing and a usage method. The device includes a shell body, a stirring device located in the shell body, and a dust suction deviceoutside the shell body. Compared with the prior art, the device utilizes openings on a stirring shaft to cooperate with the dust suction device to process materials, the separation efficiency is high, and process steps are reduced, thereby improving the ash removing efficiency; compared with a conventional process, the process no longer adopts a centrifugal principle, does not increase generationof broken rice, and cooperates with dry ice to cool the interior of the materials, the electrostatic adsorption effect is decreased, after the temperature is lowered, dust on the materials is polished down more easily, and the dust removal efficiency is improved; magnets are disposed inside an inner shell and can fully attract iron scraps, and the like in the materials, and so, production and food safety is ensured, and dust removal is more thorough; and the device is suitable for all links of unhusked rice production, has a wide range of applications, and can effectively remove the iron scraps in the materials, the iron scraps are collected in the inner shell, if the iron scraps contained in the magnets are too much, the iron scraps cannot fall into the device, and the iron removal effect is more obvious.

Owner:江西省李梦粮油有限公司

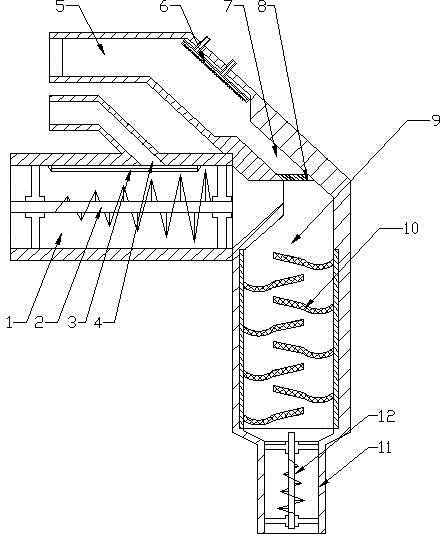

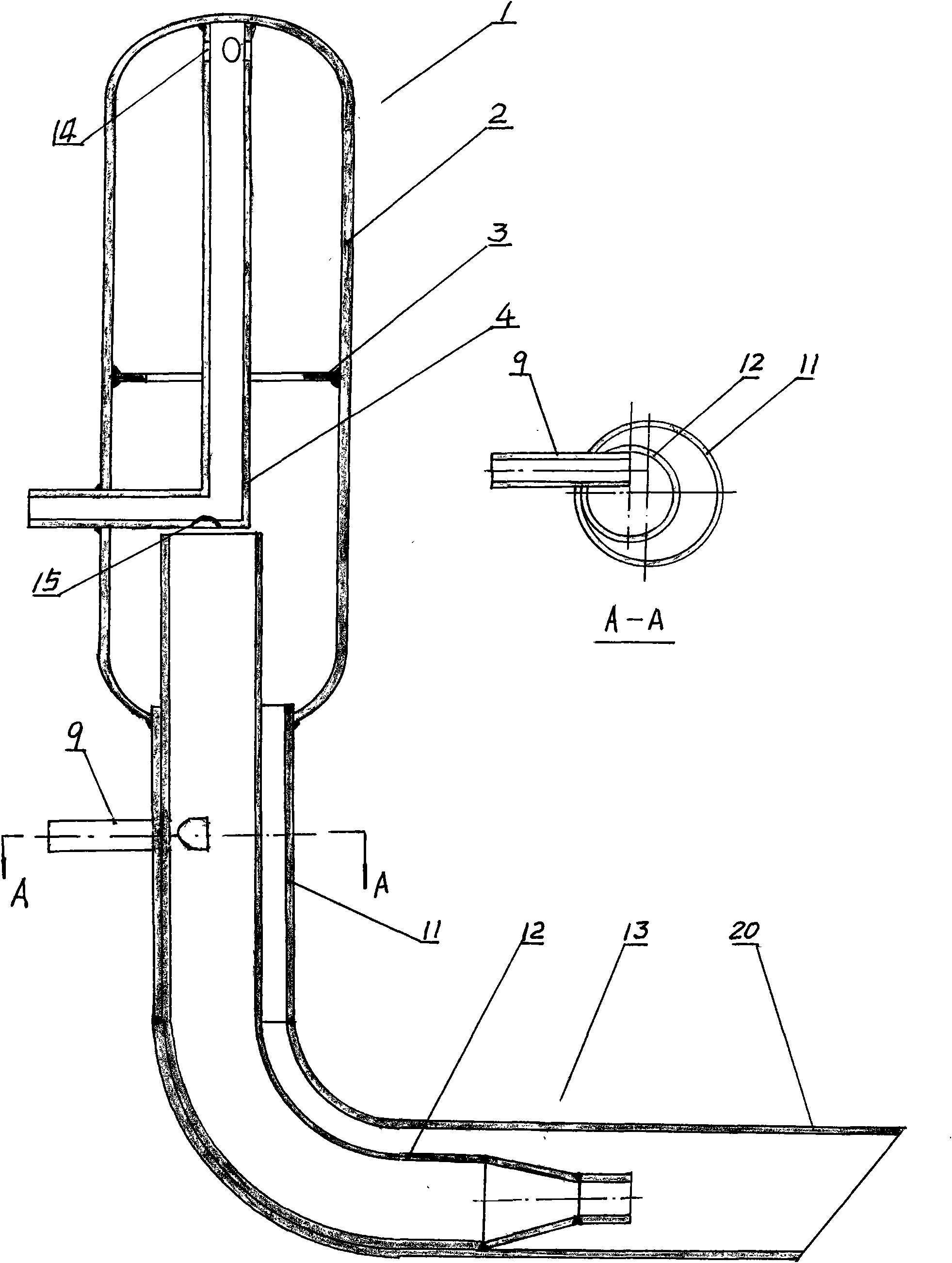

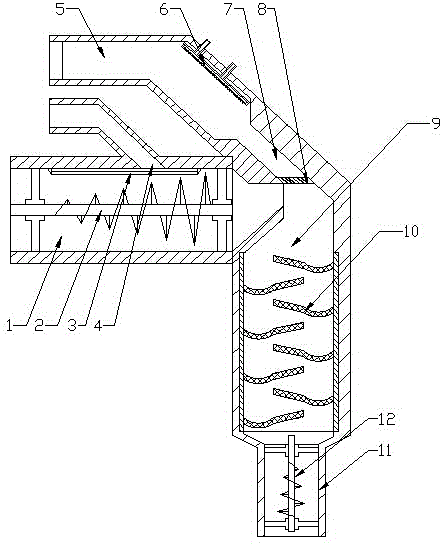

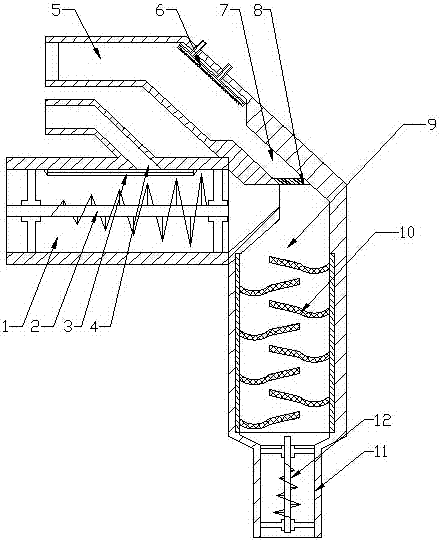

Ash removing device of tail flue of fluidized boiler

ActiveCN104613485AEfficient emissionsAchieve separationSolid removalAxial flow pumpsParticulatesFluidized bed

The invention relates to an ash removing device of the tail flue of a fluidized boiler. The ash removing device comprises a smoke inlet pipe, a cooling pipe, a separation pipe and a sedimentation pipe, wherein the axis of the columnar pipeline of the separation pipe is vertical to the ground, the open end of the columnar pipeline faces to the ground, and the smoke inlet pipe is arranged on the lateral wall of the columnar pipeline; one end of the smoke inlet pipe is communicated with the interior of the columnar pipeline, and the other end thereof is communicated with the tail flue of the fluidized boiler; the cooling pipe is mounted at the sealed end at the top of the separation pipe, the other end of the cooling pipe is communicated with the interior of the separation pipe, and a spraying component is mounted in the cooling pipe; a separator is disposed on the wall face of the separation pipe and comprises a plurality of filter plates, and the filter plates are arranged on the inner wall of the separation pipe in a zigzag and staggered manner; an exhaust pipe is arranged at the bottom of the separation pipe. The ash removing device has the advantages that smoke is absorbed through water, and separation of waste gas, particles and soluble impurities is achieved by the filtering separation mechanism.

Owner:BRIGHT THERMAL EQUIP CO LTD

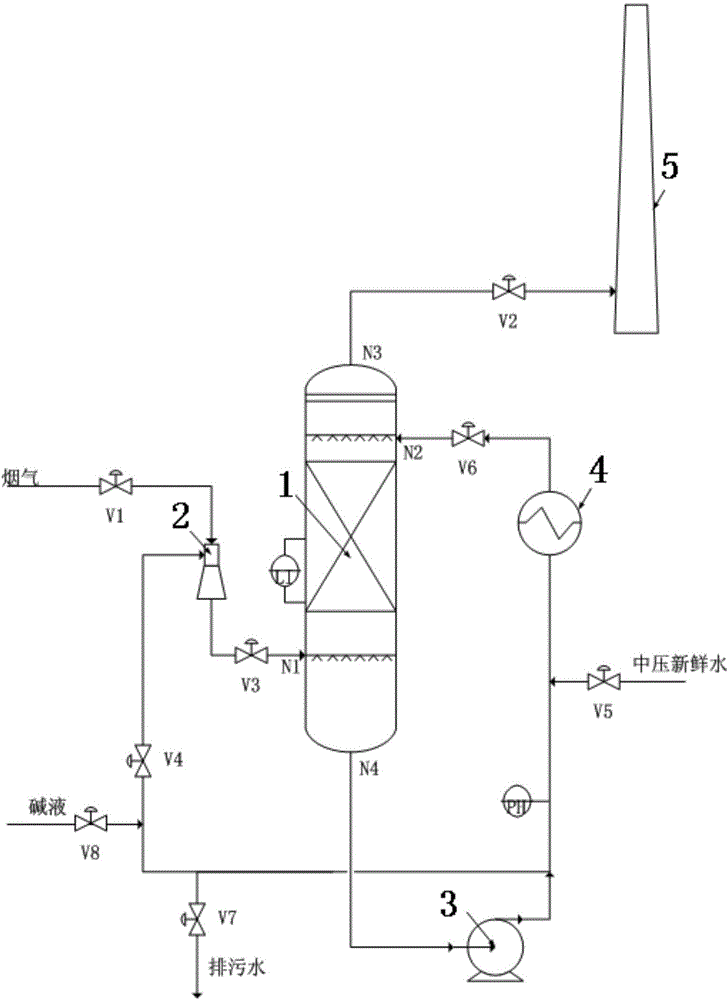

Flue gas ultra-clean wet dust collection system of power plant

InactiveCN104548826AGuaranteed liquidityPrevent sedimentation and scalingUsing liquid separation agentGreywaterScrubber

The invention discloses a flue gas ultra-clean wet dust collection system of a power plant. A scrubbing tower is communicated with a venturi scrubber connected with flue gas at the outlet of the tail part of a boiler; the bottom of the scrubbing tower is provided with a scrubbing tower circulation pump; the scrubbing tower circulation pump has two outlets, one outlet is connected with the venturi scrubber, and the other outlet is connected with a circulation water heat exchanger; an outlet of the circulation water heat exchanger is connected with a connector at the upper part of the scrubbing tower; an outlet at the top of the scrubbing tower is connected with a chimney; ash in flue gas from the tail part of the boiler is mainly removed by the venturi scrubber and the scrubbing tower; flue gas passes through the venturi scrubber, so that the ash content is soaked fully and then is removed by the scrubbing tower; ash water extracted from the lower middle part of the scrubbing tower is pressurized by a circulation pump of the scrubbing tower to act as scrubbing water of the venturi scrubber; in order to improve the removing efficiency of acid gas, an alkaline solution can be added into ash water which is introduced into the scrubbing tower; boiler feed water serving as fresh supplied water is added into the circulation solution of the tower. The system is simple in structure, is low in investment, and is high in dedusting efficiency.

Owner:HUANENG CLEAN ENERGY RES INST

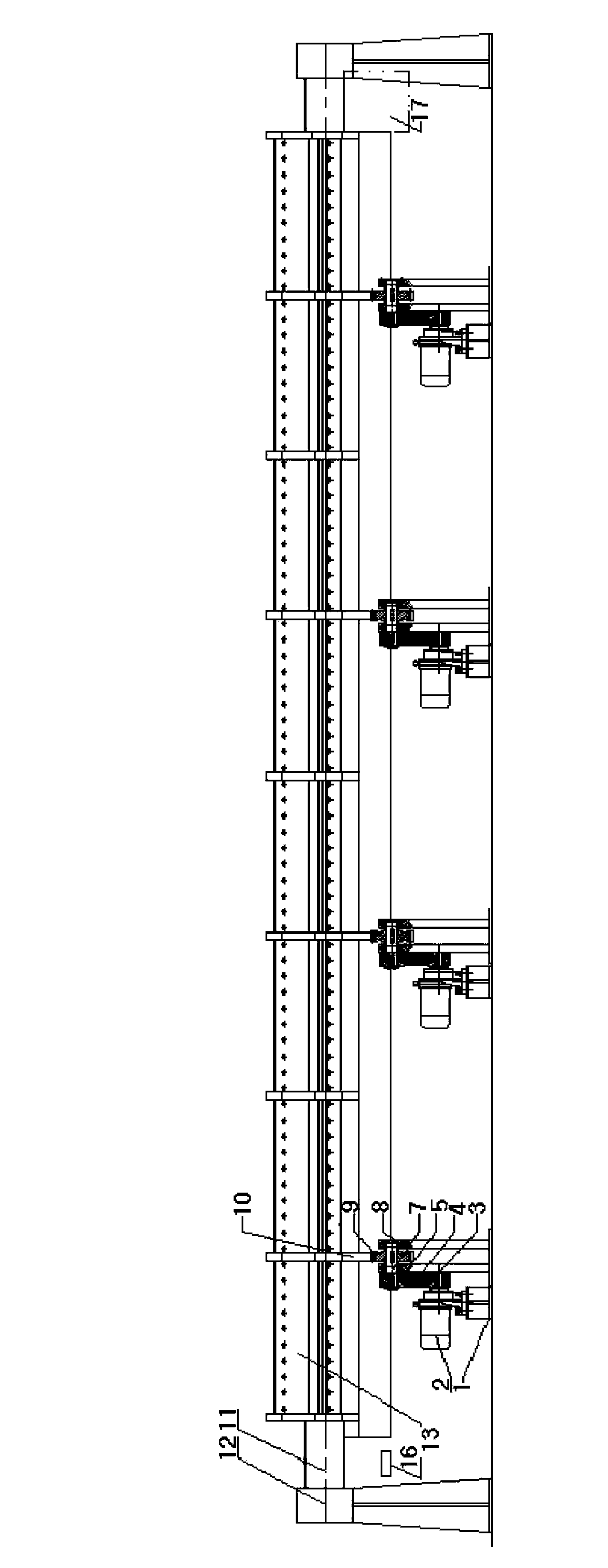

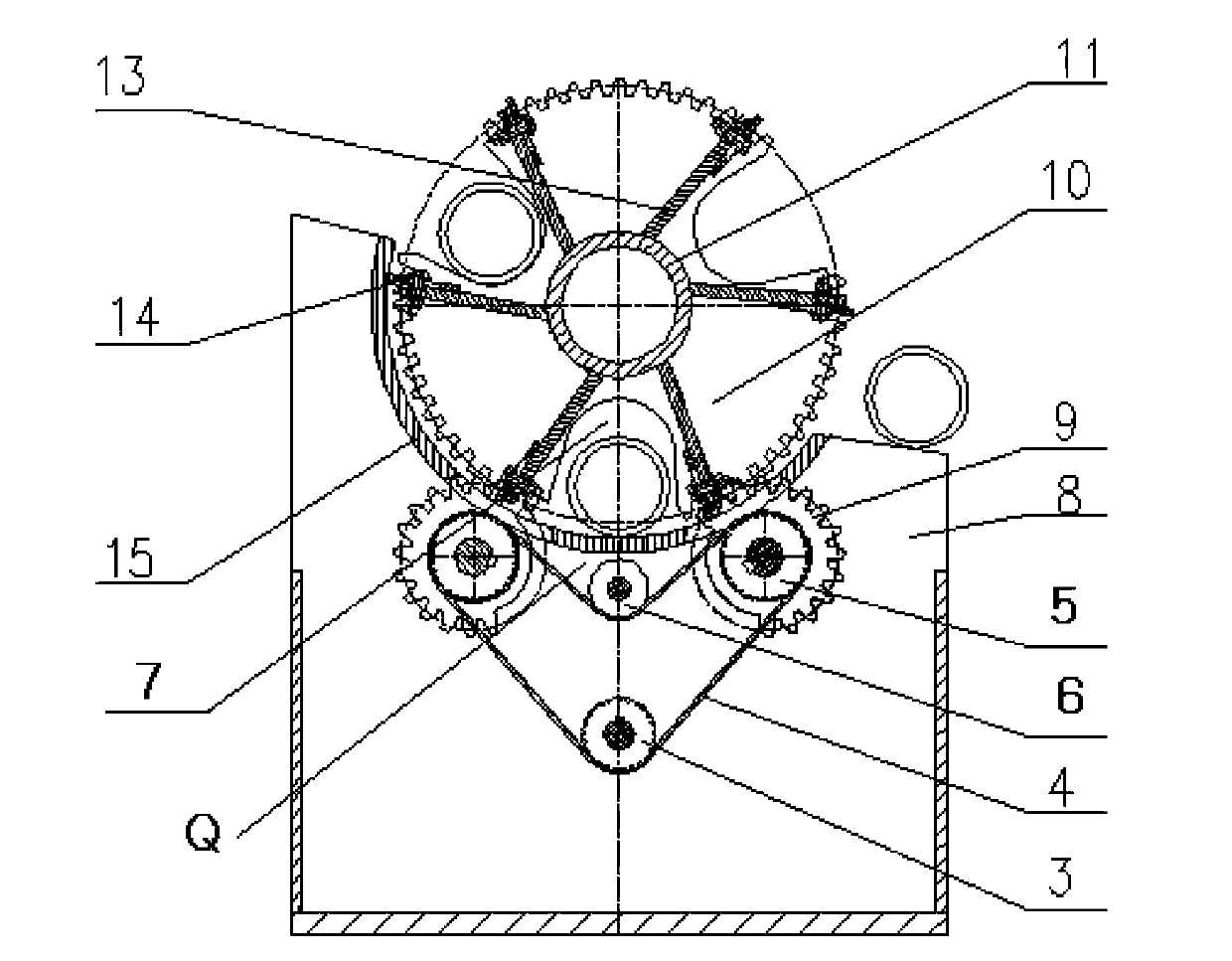

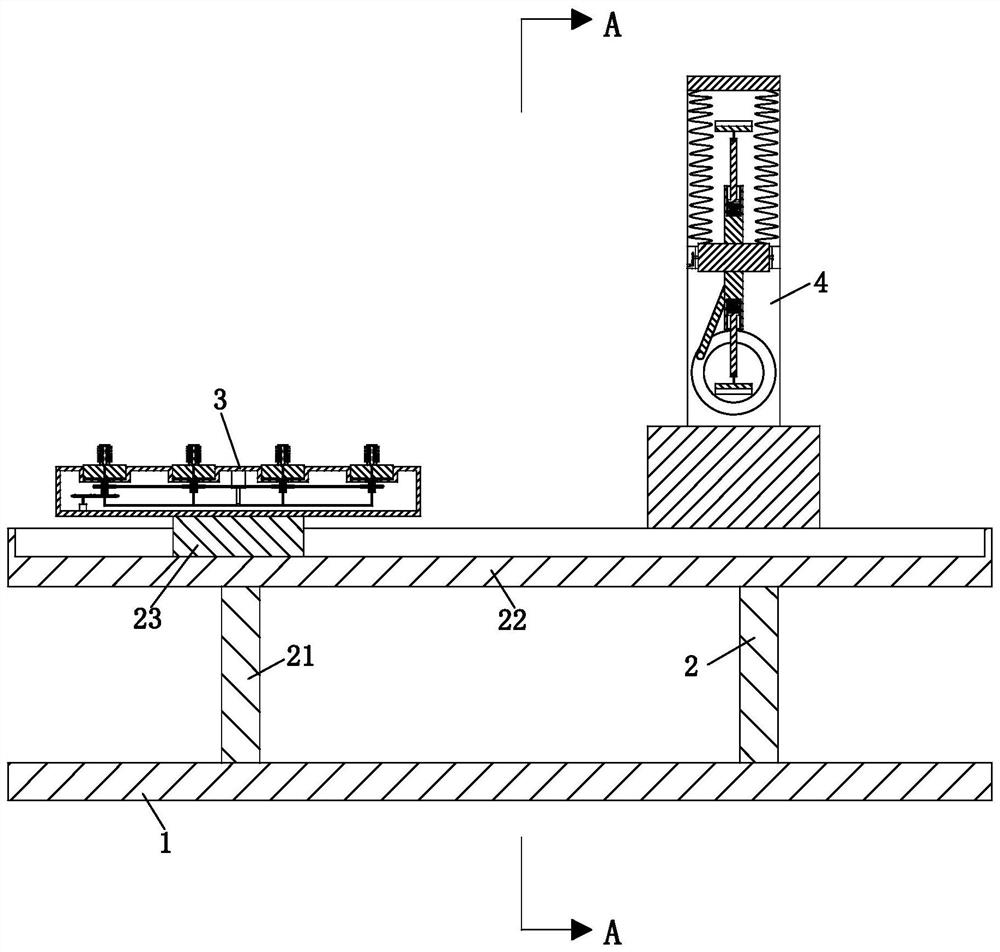

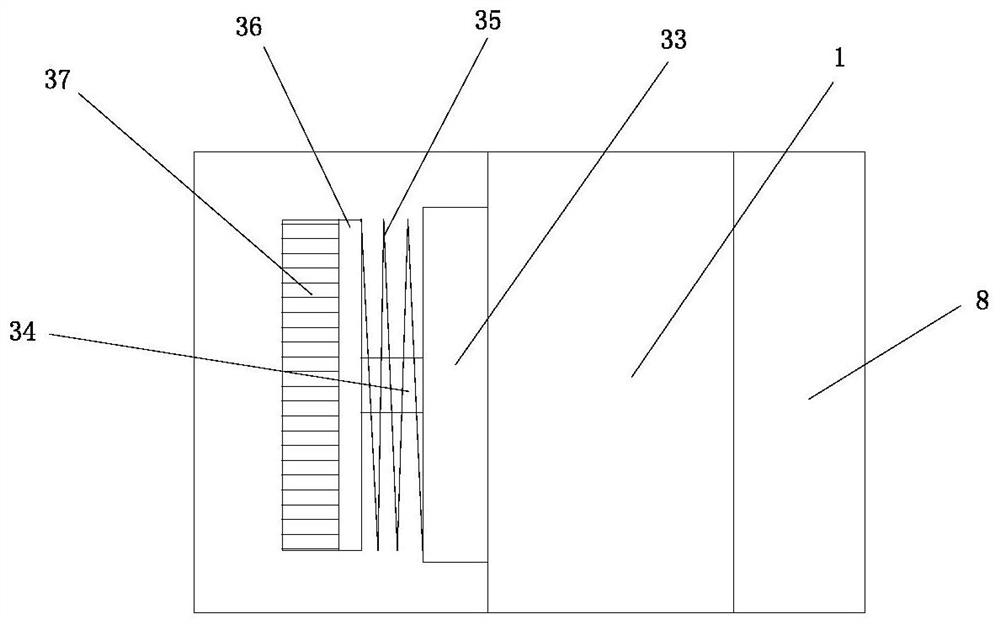

Downward-drive type device for removing dust on inner surface of steel pipe

ActiveCN103990629AReduce preparation timeReduce auxiliary timeHollow article cleaningEngineeringSteel tube

The invention discloses a downward-drive type device for removing dust on the inner surface of a steel pipe. The device comprises an air nozzle, an air suction cavity, a plurality of multi-station rotating discs, a plurality of driving assemblies and a long arc sealing plate. The distance between the air nozzle and the air suction cavity is slightly larger than the length of the steel pipe, and the air nozzle and air suction cavity are arranged at the dust removing position. The multi-station rotating discs are arranged in the axial direction of the steel pipe, at least three gaps are formed in each multi-station rotating disc, and each gap is a station. The driving assemblies are correspondingly connected with the multi-station rotating discs and drive the multi-station rotating discs to synchronously rotate with the axes of the multi-station rotating discs as rotating axes. The two sides of each station are respectively provided with a sealing side plate which is arranged in the axial direction of the steel pipe, and each sealing side plate is fixedly arranged between every two adjacent multi-station rotating discs. The long arc sealing plate is arranged below the multi-station rotating discs in the axial direction of the steel pipe, and a sealing space is formed between the long arc sealing plate and the sealing side plates at the dust removing position. The downward-drive type device for removing the dust on the inner surface of the steel pipe can rapidly and effectively remove the dust on the thin and long steel pipe and improve reliability and working efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD

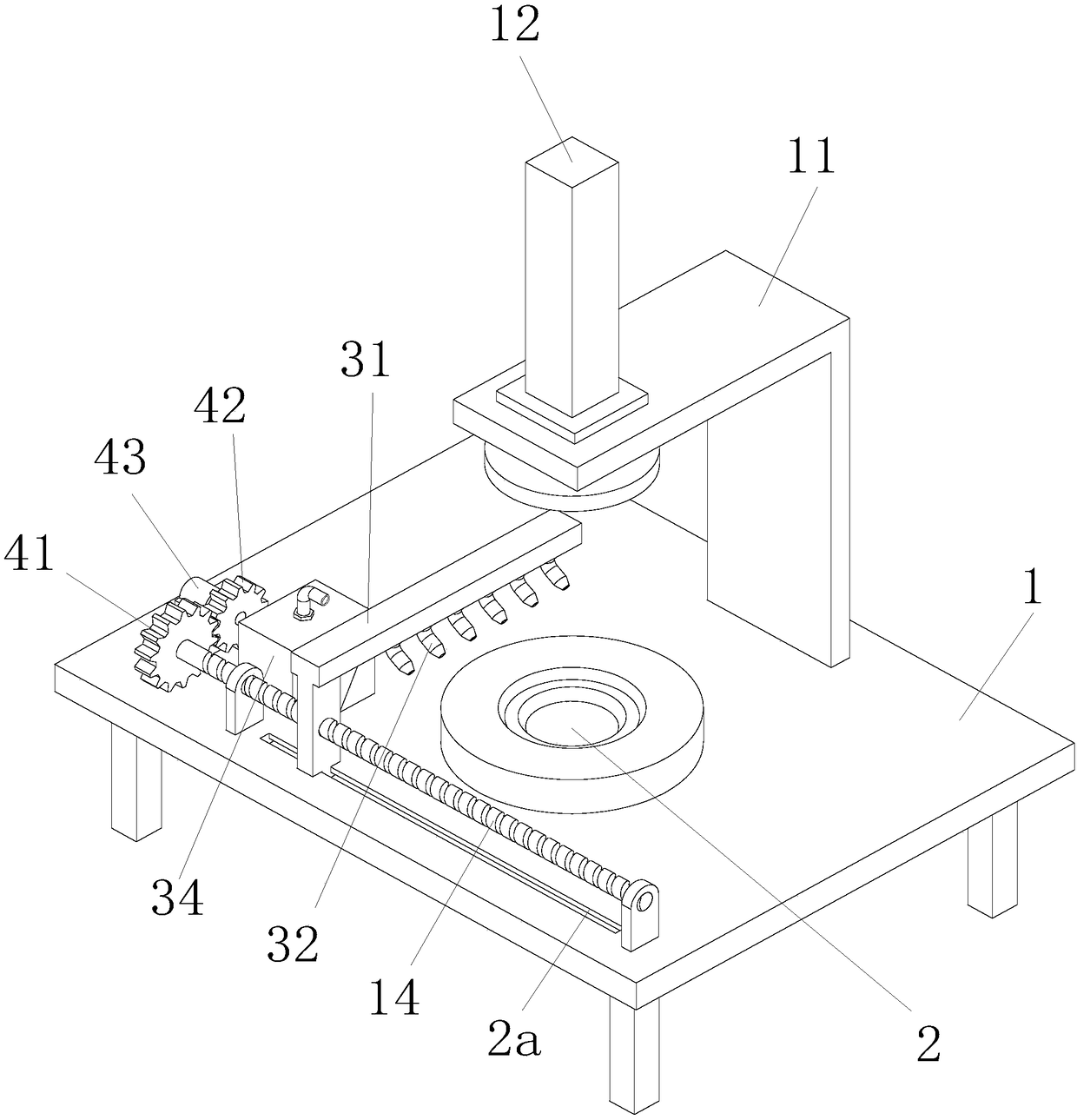

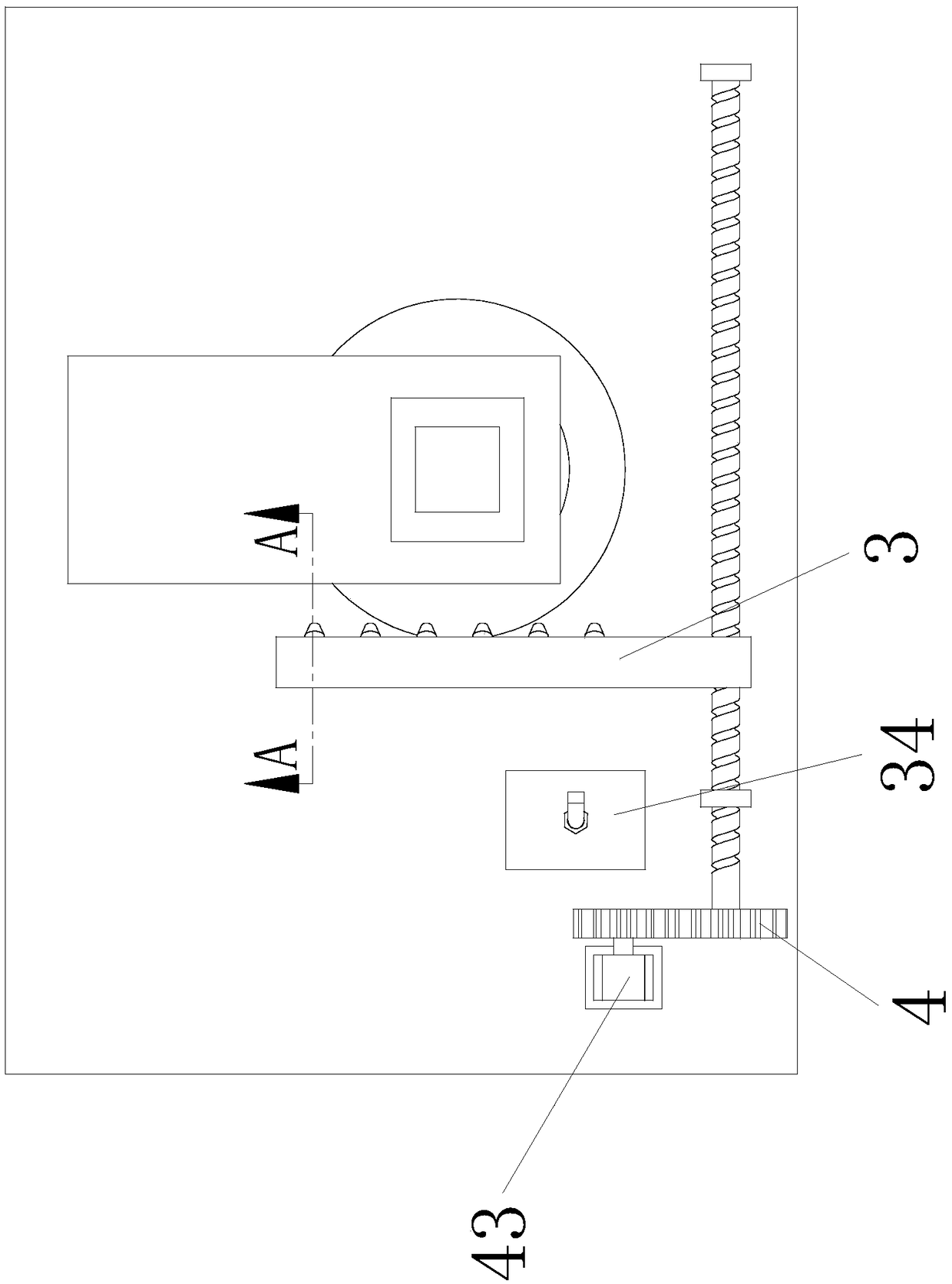

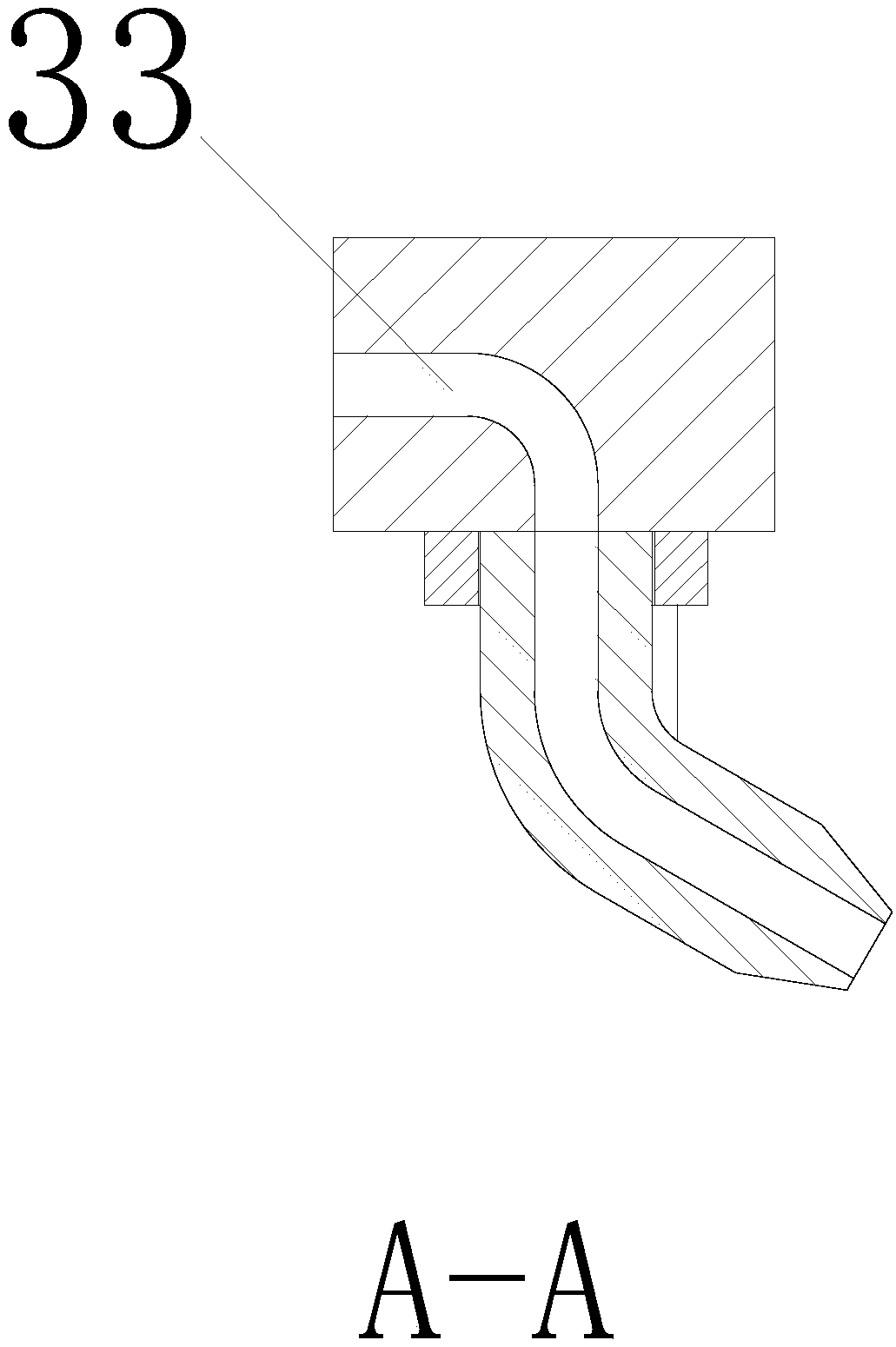

Pneumatic cleaning die

InactiveCN108906781AAvoid secondary damageSimple structureCleaning using gasesPressesHydraulic cylinderFixed frame

The invention relates to a pneumatic cleaning die. The die comprises a workbench and a lower die located in the middle of the workbench. The workbench is further provided with a fixing frame, and a hydraulic cylinder and an upper die connected with the hydraulic cylinder and matched with the lower die are installed on the fixing frame. The die further comprises a sliding water spraying mechanism in the length direction of the workbench and a lead screw which is matched with the water spraying mechanism and installed on the workbench. A power mechanism capable of making the lead screw rotate isfurther installed on the workbench. The die can be automatically cleaned, does not need to be disassembled and is simple in structure. An air jetting mechanism can completely cover the surface of thelower die, and the cleaning area is increased, so that the dust removal efficiency is improved, a cleaning fluid does not need to be used, the die is prevented from being corroded by surface residues, and secondary damage caused by residue cleaning to the die is effectively eliminated.

Owner:台聪

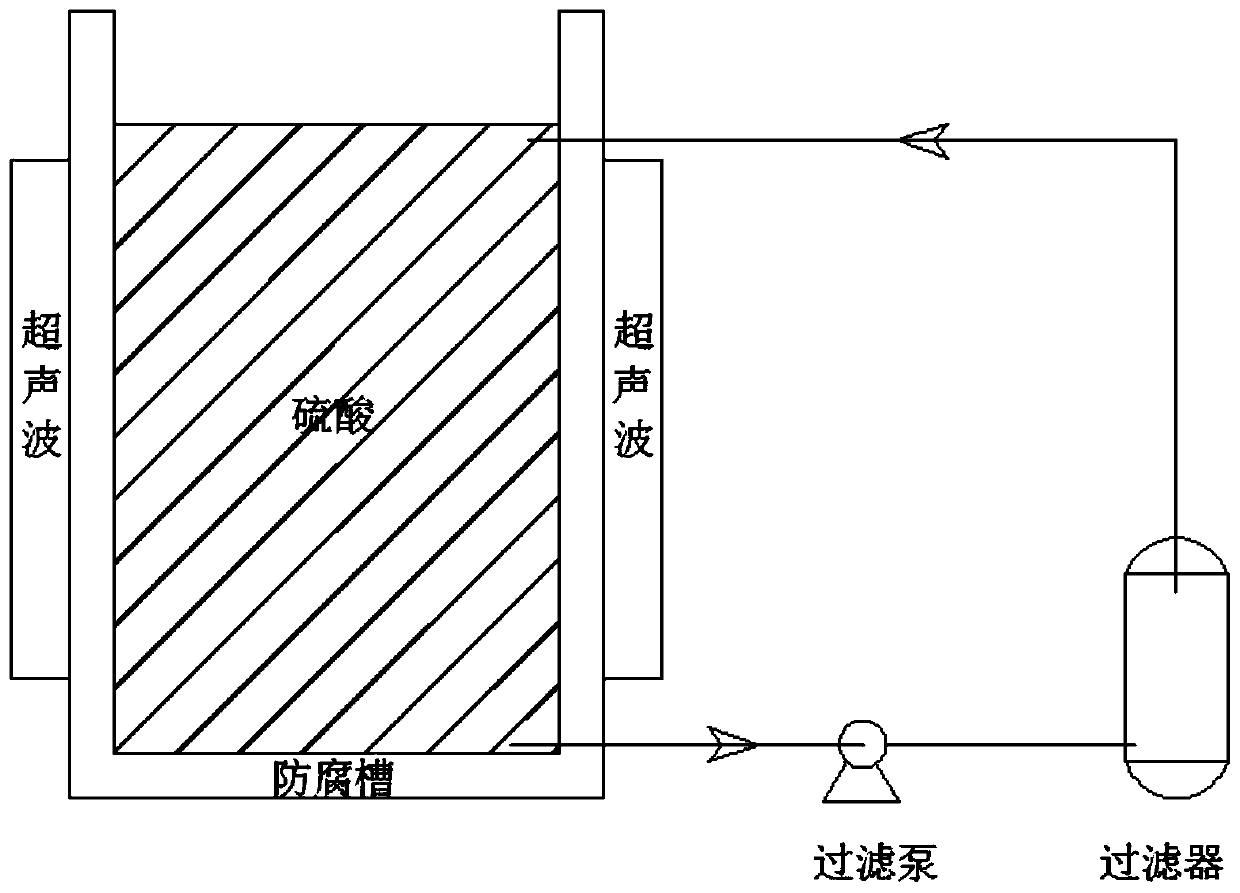

Efficient environmental-protection aluminum alloy alkali ash removing method

InactiveCN110079847AImprove protectionExtended service lifeSurface reaction electrolytic coatingHazardous substanceAnodic oxidation

The invention belongs to the field of aluminum alloy surface treatment, and relates to an efficient environmental-protection aluminum alloy alkali ash removing method. The method comprises the steps of blank loading, sulfuric acid degreasing, alkali erosion, ash removal, anodic oxidation and hole sealing drying; in the ash removal process, aluminum alloy profiles after the alkali erosion are placed in a corrosion resisting tank with 120-220 g / L of sulfuric acid solution for dipping by 0.1-3 min; the corrosion resisting tank is placed in ultrasonic equipment; environmental-protection sulfuric acid is matched with ultrasonic waves for removing alkali ash after alkali erosion of aluminum alloys, so that the ash removing efficiency is improved; and meanwhile, the sulfuric acid with the same components with an oxidation tank is used for removing the ash to prevent harmful substances from entering the oxidation tank, so that the service life of the oxidation tank is prolonged, the environmental problem is solved, and the production cost is reduced.

Owner:CHINA ZHONGWANG

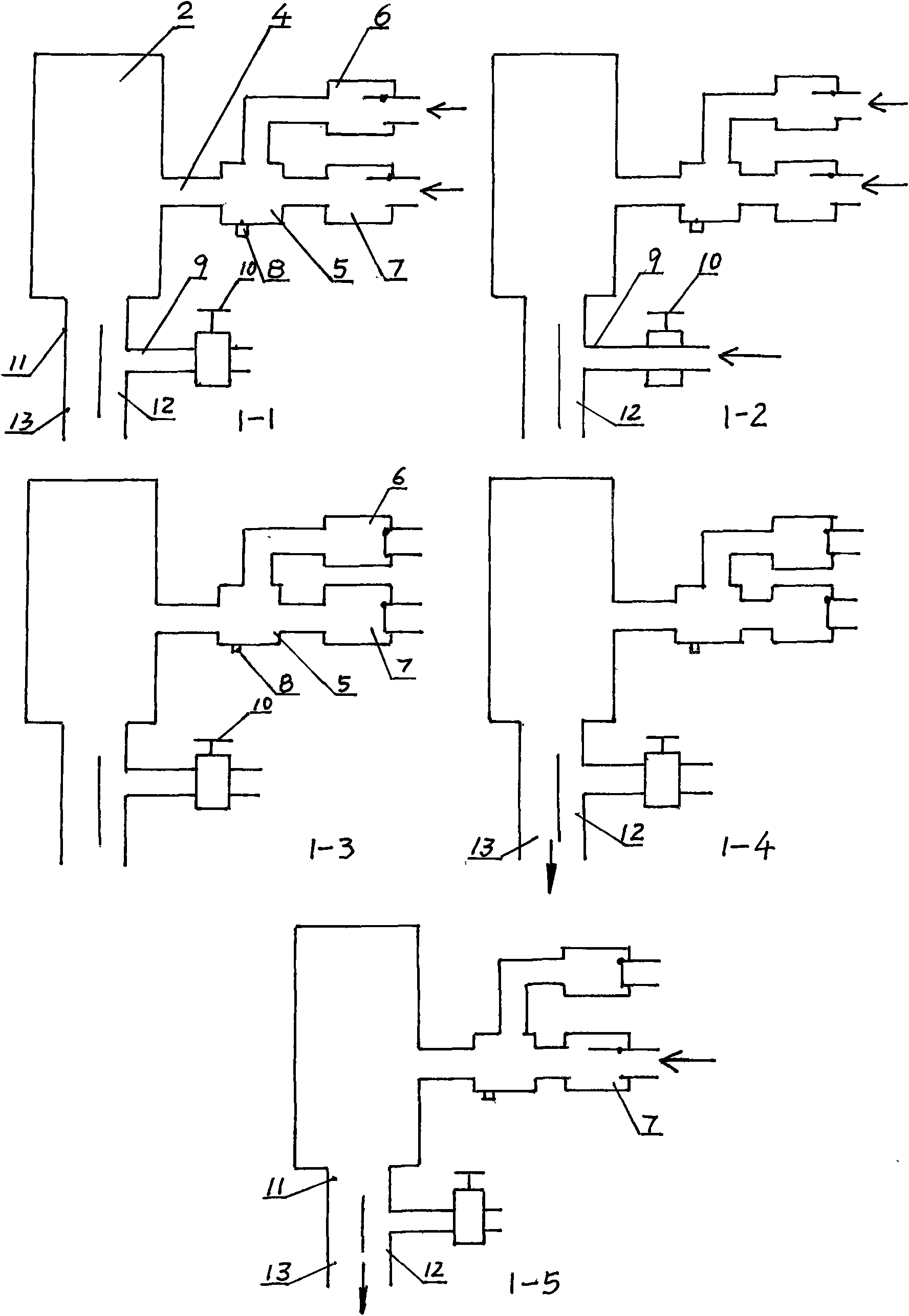

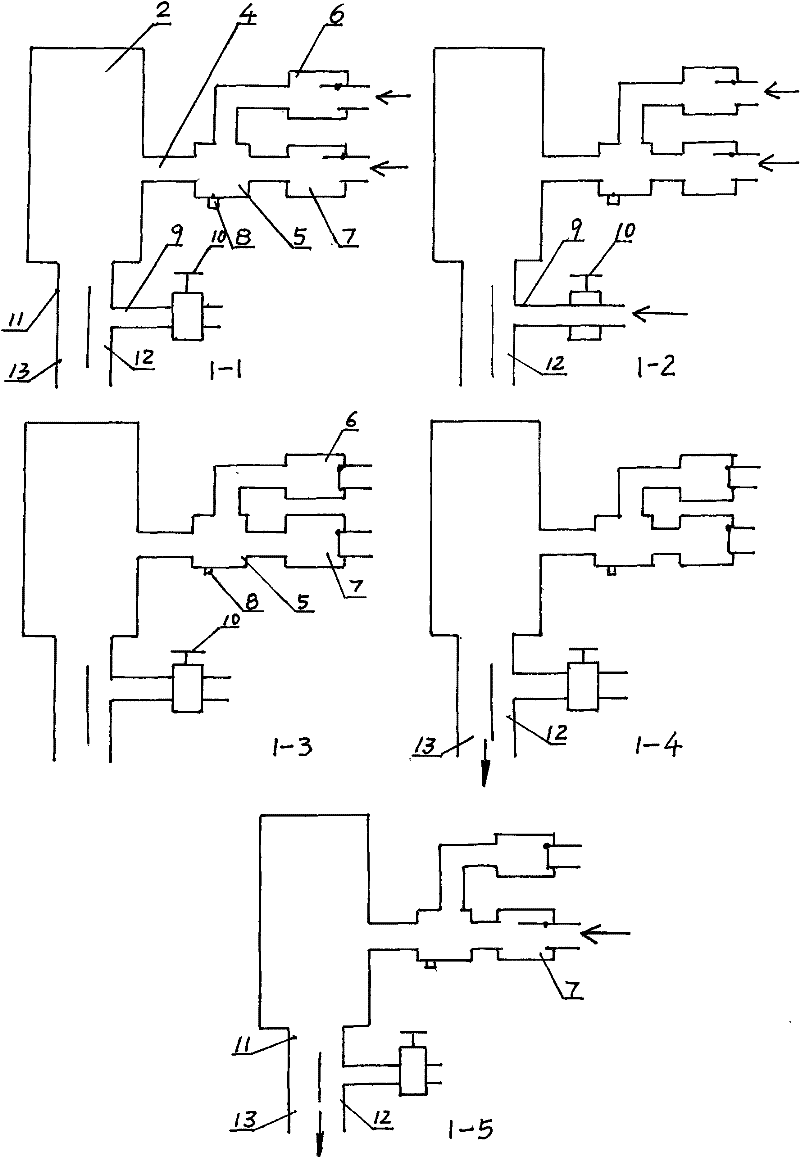

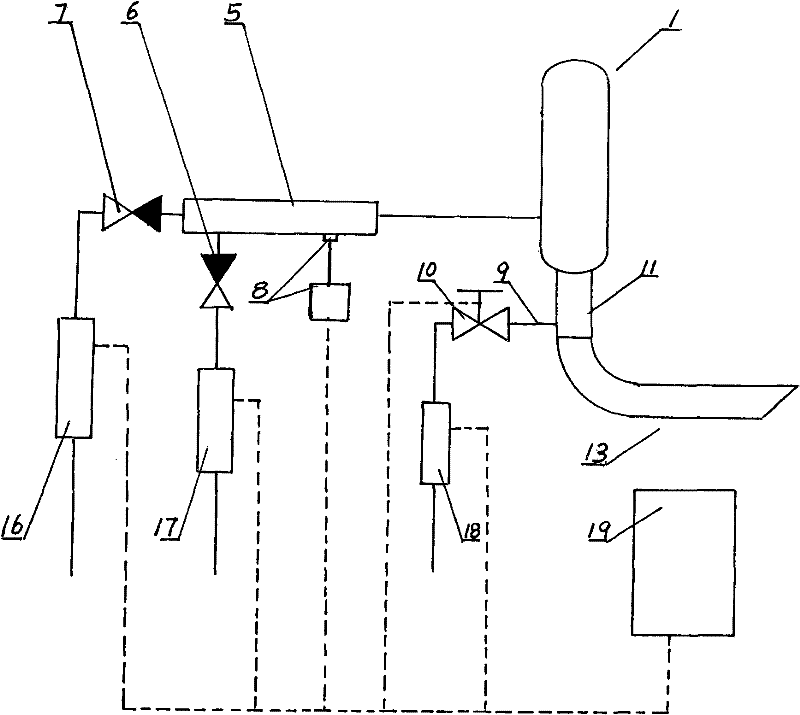

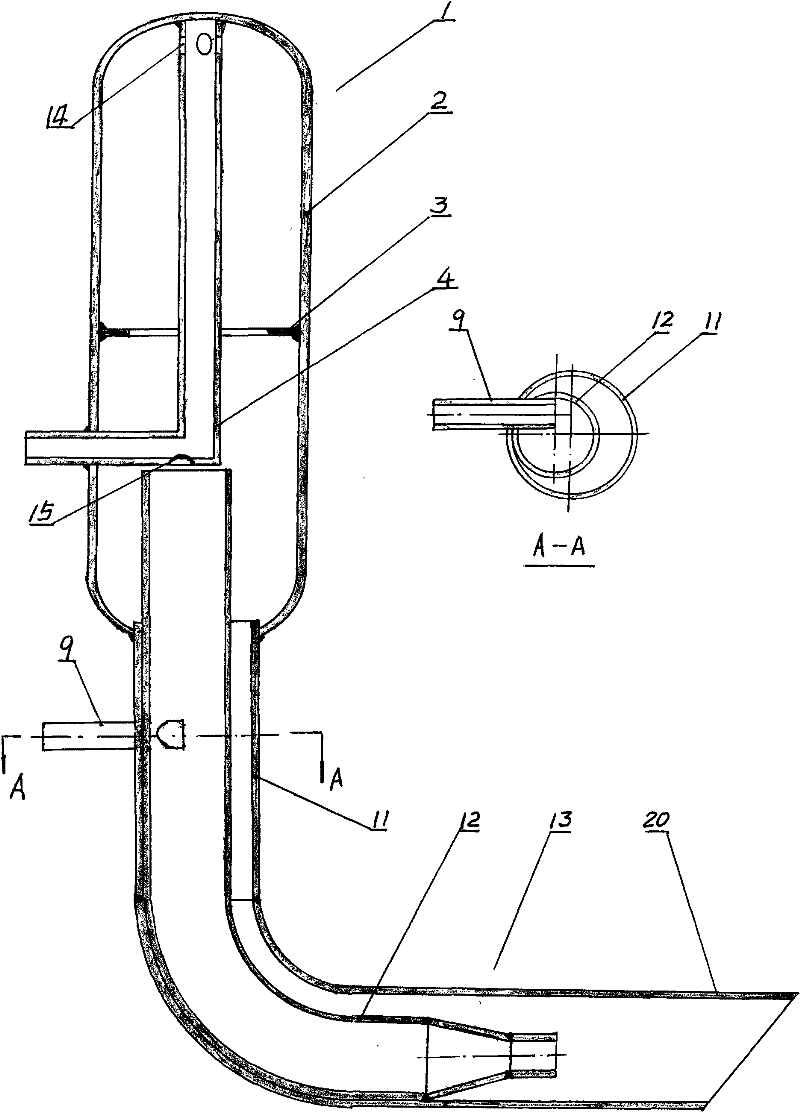

Boiler pulse soot-blowing method and device thereof

The invention provides a boiler pulse soot-blowing method, which comprises the following steps: filling mixed gas of inflammable gas and air into a tank body, and then filling water into an outlet pipe and a nozzle connected with the tank body; igniting the inflammable mixed gas, and then spraying the detonated gas along with water out of the nozzle; filling air into the tank body, the outlet pipe and the nozzle, and then eliminating waste gas; and finally repeating the above steps to form a water-containing pulse shock wave at the outlet of the nozzle for carrying out boiler soot-blowing. The invention further provides a boiler pulse soot-blowing device for realizing the method, and the boiler pulse soot-blowing device is composed of a gas pipeline and a metering input distributor, an air pipeline and a metering input distributor, a water supply pipeline and a metering input distributor, a shock wave generator, a nozzle, a water inlet pipe and a water inlet valve, wherein the nozzle is equipped with a water jetting pipe communicated with the water inlet pipe, and the water inlet pipe is equipped with the water inlet valve. The boiler pulse soot-blowing device of the invention has simple structure, wide application range, convenient and flexible operation and long service life.

Owner:周慧民

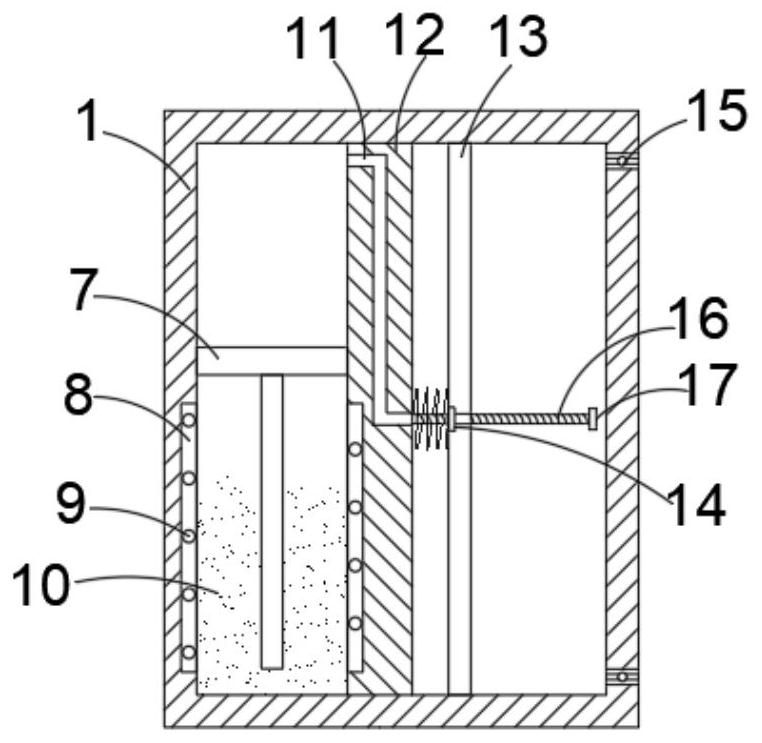

Steady dustproof cloth bag provided with vibrating mechanism

InactiveCN106474838AImprove ash removal efficiencyAvoid cloggingDispersed particle filtrationEngineeringPower flow

The invention discloses a steady dustproof cloth bag provided with a vibrating mechanism. The steady dustproof cloth bag comprises a cloth bag bone shell, a strong gas flush spray pipe is vertically arranged at the position of the middle of the net body of a current blocking net plate, an even backflush nozzle is mounted at the position of the top of the pipe body of the strong gas flush spray pipe, a small vibrating machine is arranged in the upper middle of the plate body of a horizontal mounting plate, manual lifting handles are arranged on left and right sides of the peripheral side wall of the top of the cloth bag bone shell, screw installation blocks are arranged on lower side walls of the manual lifting handles, and circular fastening clamp rings are arranged on the middle and lower peripheral walls of the cloth bag bone shell in a sleeved manner. By the arrangement, the shortcoming of frequent plugging due to too much accumulation in small holes of a traditional cloth bag is overcome, a small amount of dust attached to the bottom wall of the cloth bag is vibrated to float due to constant vibration of the small vibrating machine, and any falling of the cloth bag during long time use is assuredly avoided.

Owner:广西金邦泰科技有限公司

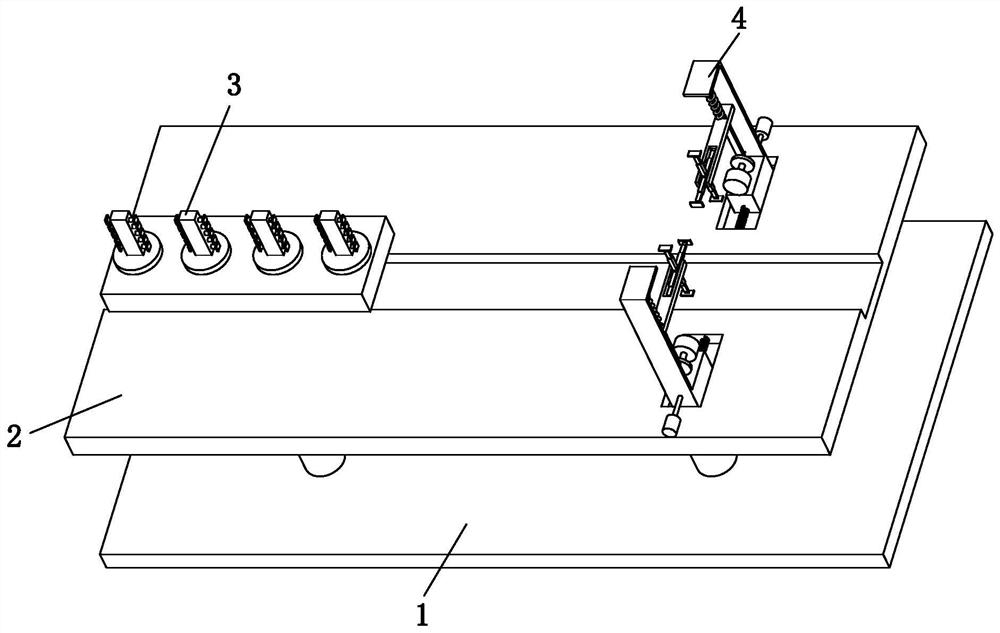

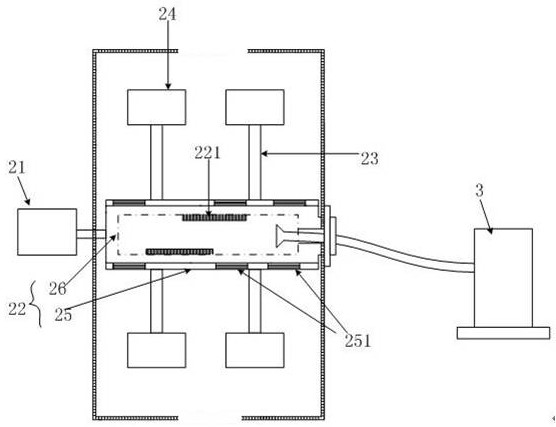

Electrostatic spraying method for aluminum profile manufacturing

InactiveCN113020134AReduce participationLow costLiquid surface applicatorsCoatingsStructural engineeringMaterials science

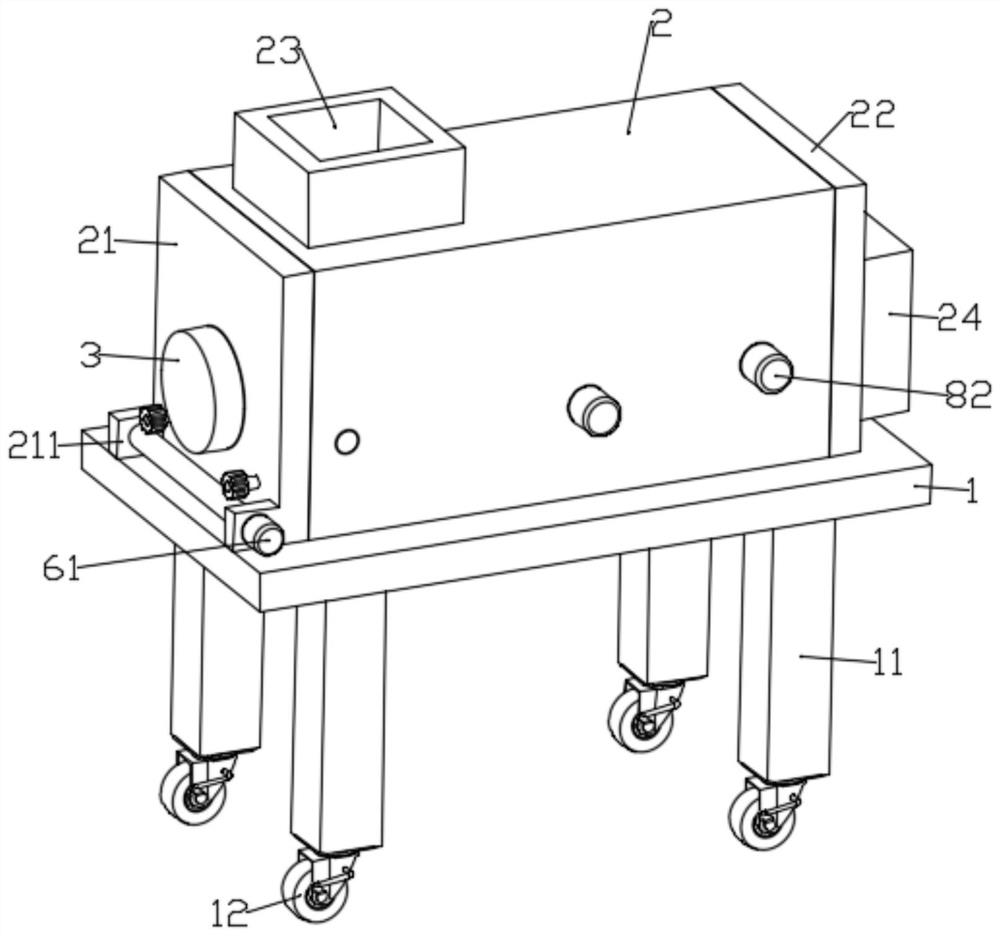

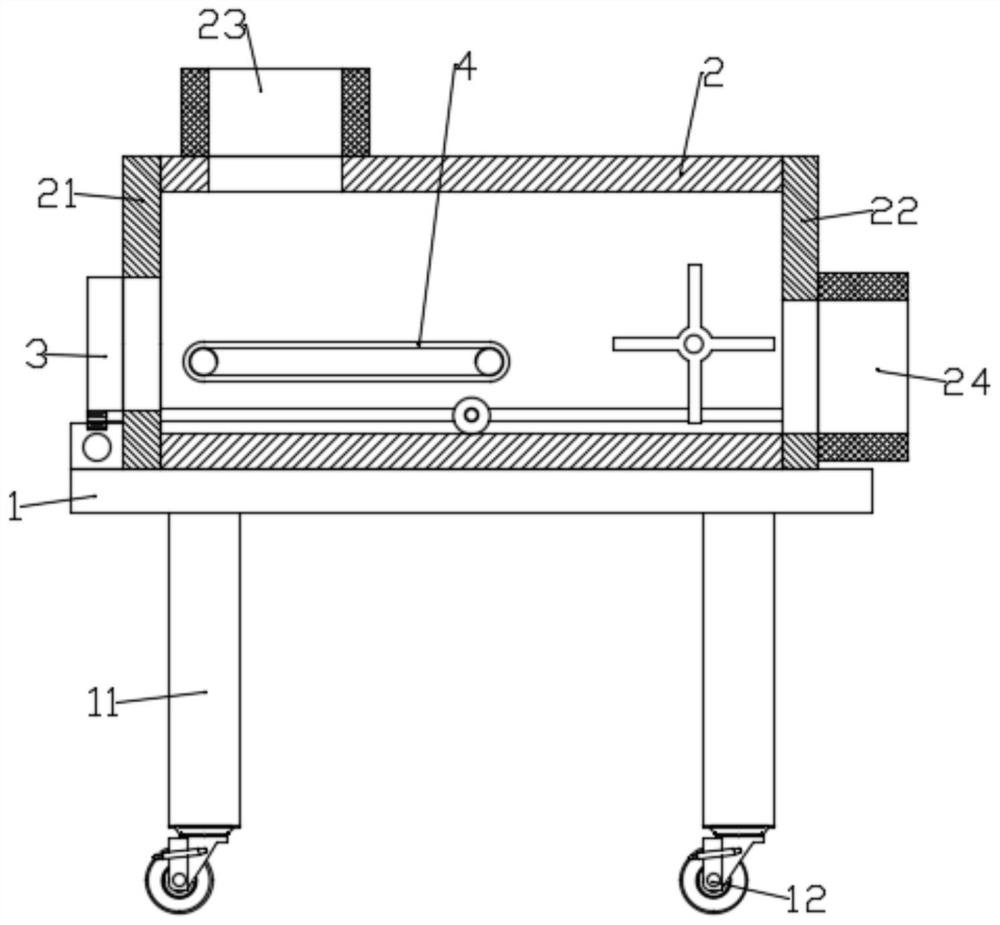

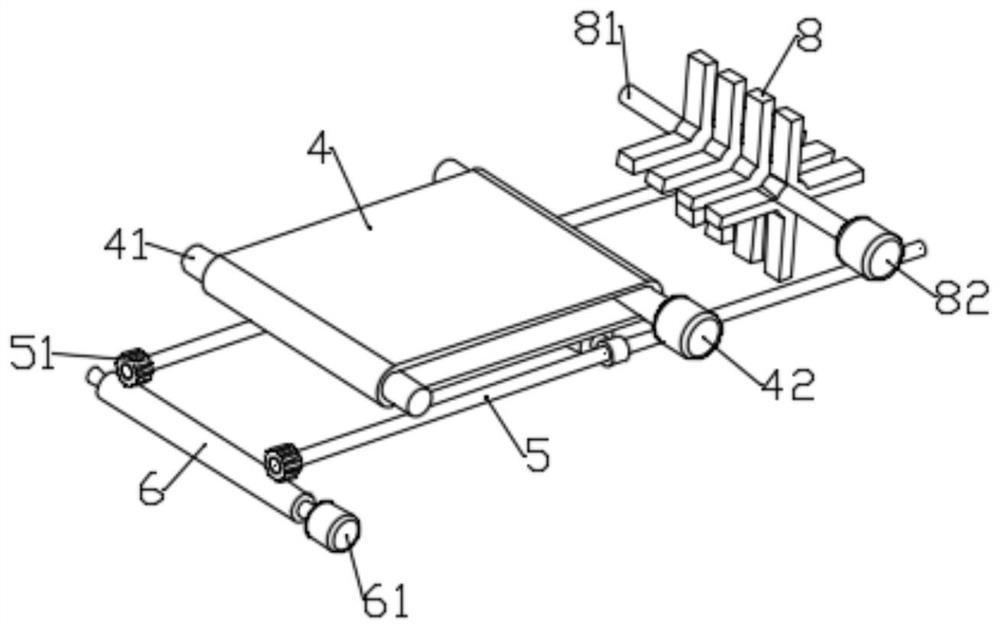

The invention relates to an electrostatic spraying method for aluminum profile manufacturing. The method involves a bottom plate, a conveying device, a fixing device and dust removing devices, wherein the conveying device is fixedly arranged on the upper end face of the bottom plate, the fixing device is installed at the position, close to the left end, of the upper end face of the conveying device, and the dust removing devices are symmetrically arranged at the position, close to the right end, of the upper end face of the conveying device front and back. The method can solve the following problems possibly occurring in the dust removing process of an existing aluminum profile that a, adhesion treatment is manually performed on the surface of the aluminum profile through adhesion equipment to remove dust attached to the surface of the aluminum profile, and the mode can cause high labor intensity of dust removing personnel and lead to low dust removing efficiency due to high time consumption; and b, the situation of missing adhesion or incomplete adhesion often occurs during manual dust removing, so that the subsequent electrostatic spraying process is influenced, and consequently the production quality of the aluminum profile is poor.

Owner:聂爱珠

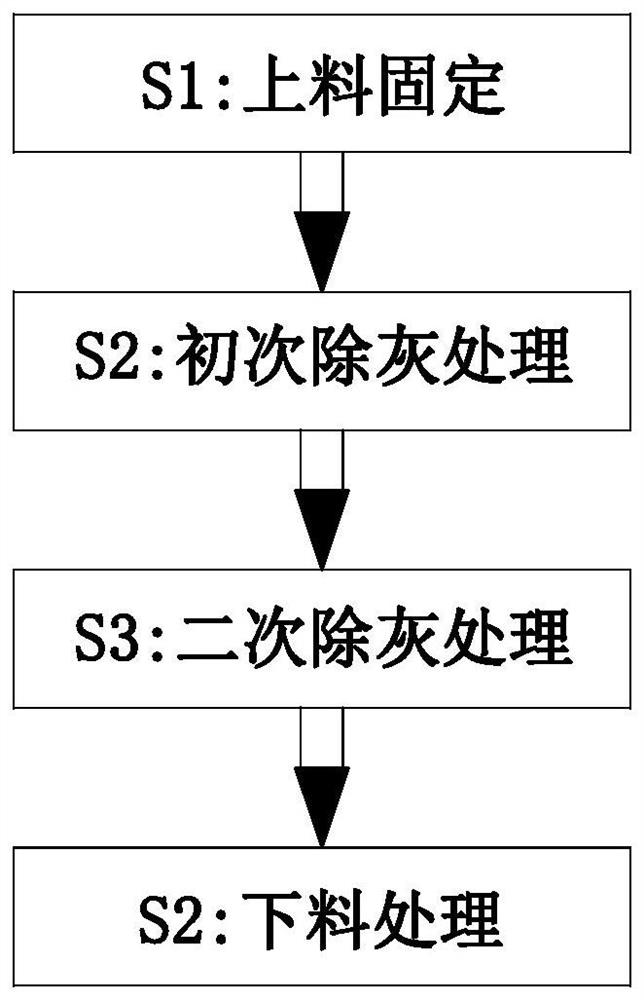

Ash removal method for high-sulfur coal after high-temperature gasification

InactiveCN111575064AReduce pollutionImprove ash removal efficiencyGas dust removalCyclonic separationProcess engineering

The invention discloses an ash removal method for high-sulfur coal after high-temperature gasification, and belongs to the technical field of ash removal. The ash removal method after high-temperaturegasification of the high-sulfur coal comprises the following steps: step 1, performing cyclone separation; step 2, performing filtering; step 3, performing primary treatment of fly ash; step 4, performing secondary treatment of the fly ash; and step 5, performing discharging. The ash removal method for the high-temperature gasified high-sulfur coal has the advantages of being high in ash removalefficiency, easy and convenient to operate, low in energy consumption, low in treatment cost, small in environmental pollution and the like.

Owner:SHANXI LUAN COAL BASED CLEAN ENERGY

A flue gas purification device at the tail of a fluidized boiler

ActiveCN104624007BEfficient emissionsAchieve separationCombination devicesLighting and heating apparatusParticulatesFlue gas

The invention relates to a tail flue gas purification device for a fluidized boiler. The tail flue gas purification device comprises a flue gas inlet pipe, a cooling pipe, a separating pipe and a settling pipe, wherein the axis of a cylindrical pipeline of the separating pipe is perpendicular to the ground, and the opening end of the cylindrical pipeline is arranged towards the ground; the flue gas inlet pipe is arranged on the side wall of the cylindrical pipeline, and one end of the flue gas pipe is communicated with the inside of the cylindrical pipeline; the other end of the flue gas pipe is communicated with a tail flue of the fluidized boiler, and the cooling pipe is arranged at the closed end of the top of the separating pipe; one end of the cooling pipe is communicated with the inside of the separating pipe, and a spraying assembly is arranged in the cooling pipe; a separator is arranged on the wall surface of the separating pipe, and comprises a plurality of filter plates which are arranged on the inner wall of the separating pipe in a zigzag staggering manner, and an exhaust duct is arranged at the bottom of the separating pipe. The flue gas is absorbed by water, and the flue gas can be separated from particulate matter and soluble impurities by a separating mechanism for filtering.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

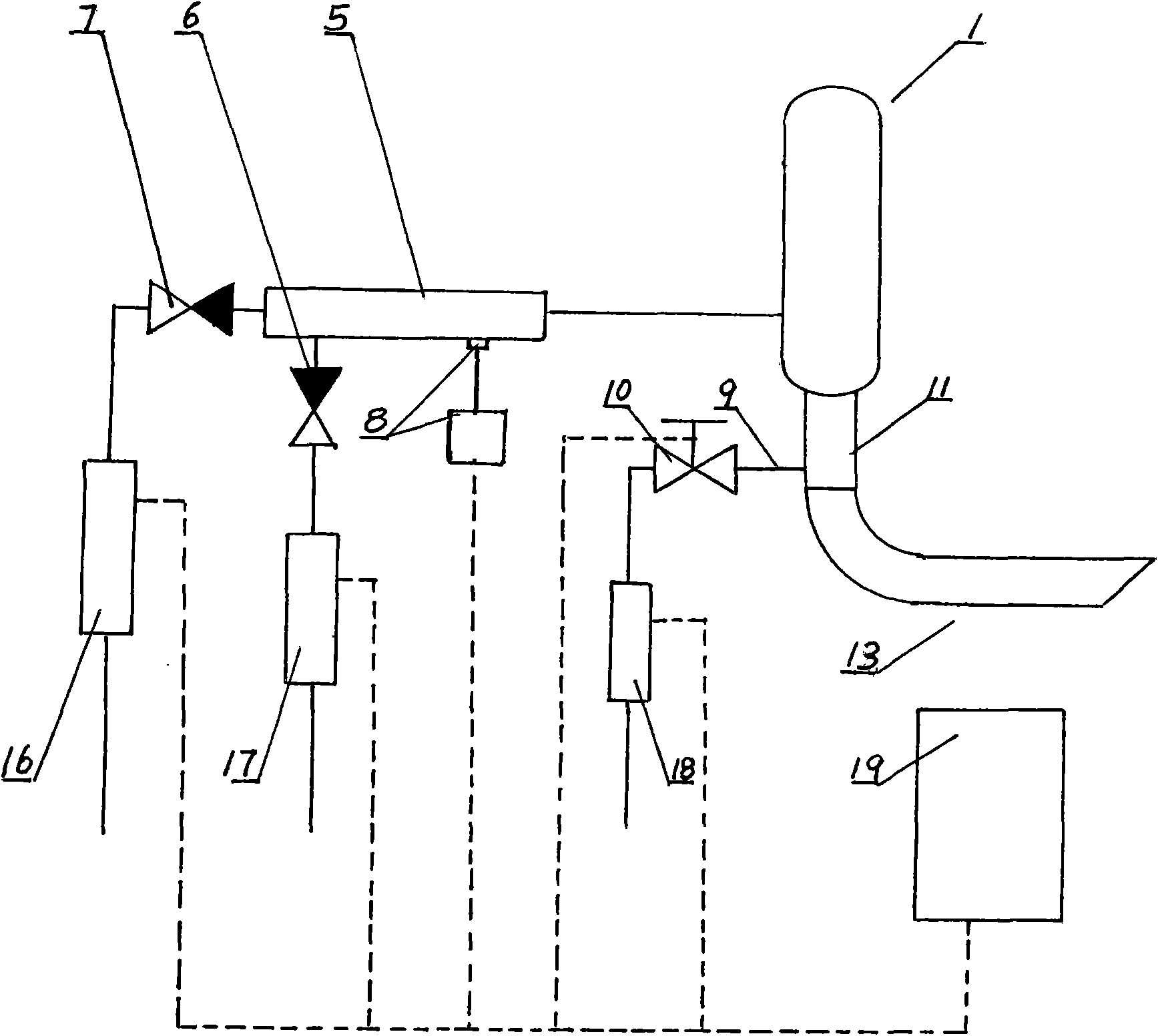

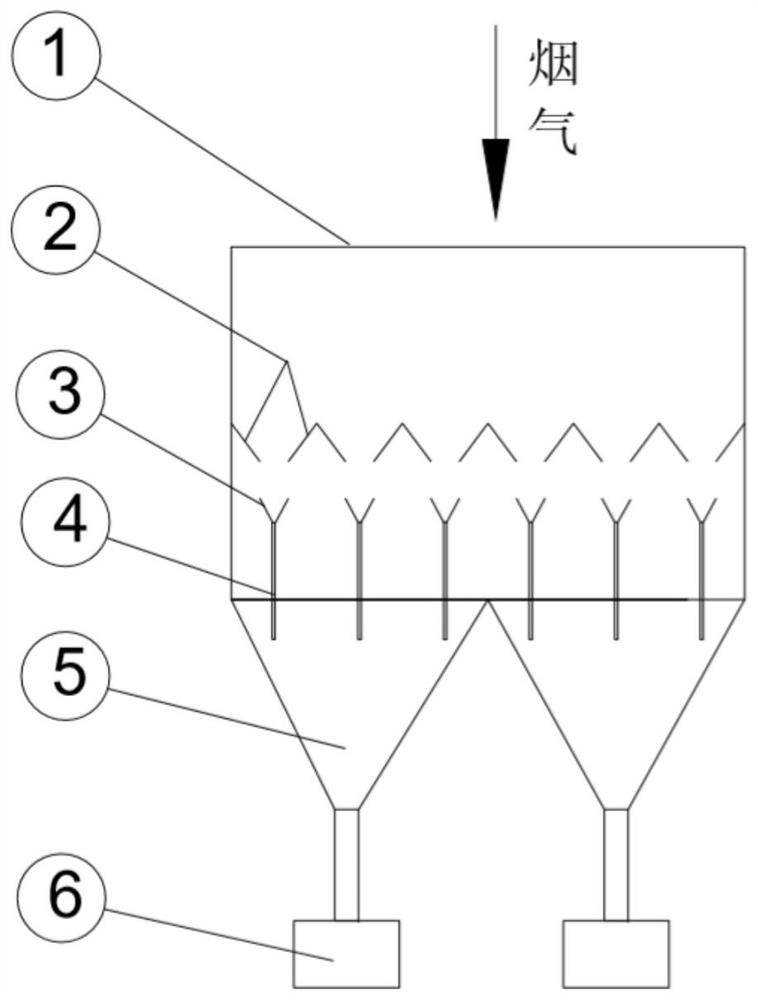

Device and method for pre-removing coarse particle ash in front of SCR denitration device

PendingCN111841155AImprove ash removal efficiencyLess investmentLighting and heating apparatusDispersed particle separationThermodynamicsFlue gas

The invention discloses a device and method for pre-removing coarse particle ash in front of an SCR denitration device. The device comprises an economizer outlet flue, an economizer ash hopper, a plurality of baffle plates, a plurality of ash collecting hoppers and a plurality of ash falling pipes. A flue gas inlet is formed in the top of the economizer outlet flue, the baffle plates are sequentially distributed in the economizer outlet flue, the baffle plate on the outermost side is fixed on the outer wall of the economizer outlet flue, the baffle plate on the outermost side is obliquely distributed, the other baffle plates are of herringbone structures or other structural forms capable of enriching dust and guiding the dust into the dust collecting hoppers, a gap is formed between everytwo adjacent baffle plates, wherein one gap corresponds to one ash collecting hopper and one ash falling pipe, the ash collecting hopper is located below the corresponding gap, a bottom outlet of theash collecting hopper is communicated with the upper end of the corresponding ash falling pipe, and the lower ends of the ash falling pipes penetrate through the side wall of the economizer outlet flue to be inserted into the economizer ash hopper. The device and the method can effectively improve the ash collecting effect of the economizer flue.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

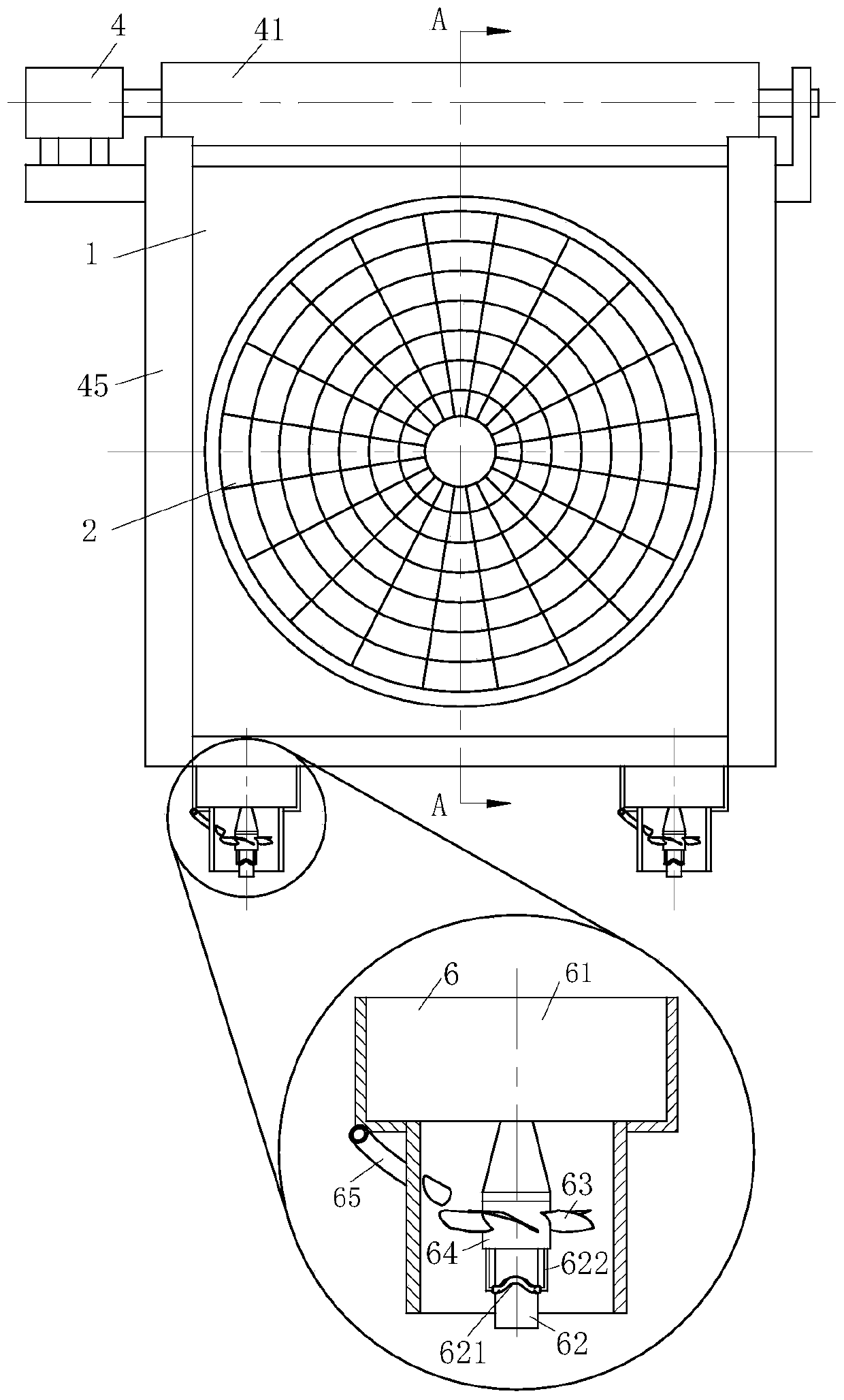

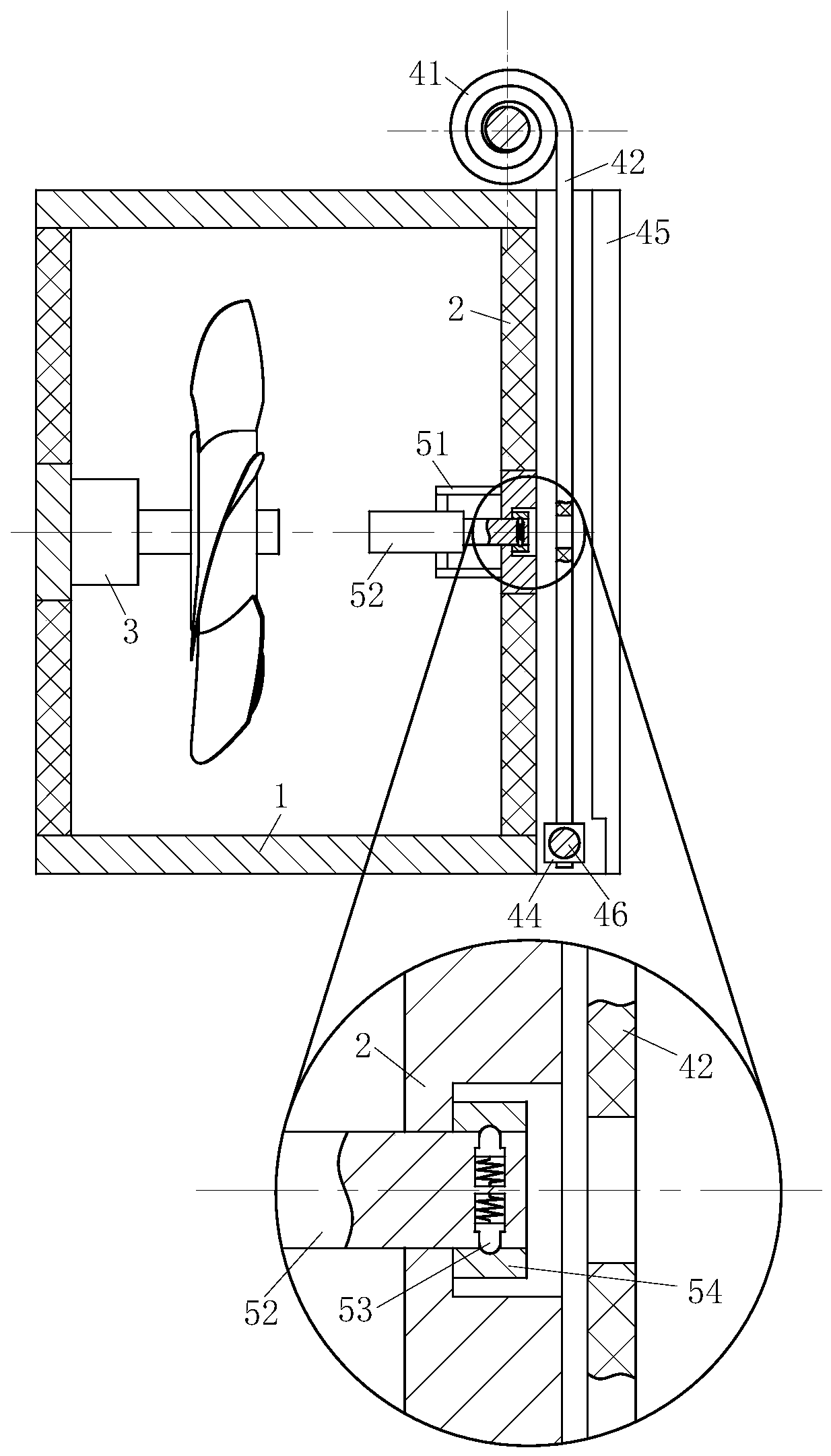

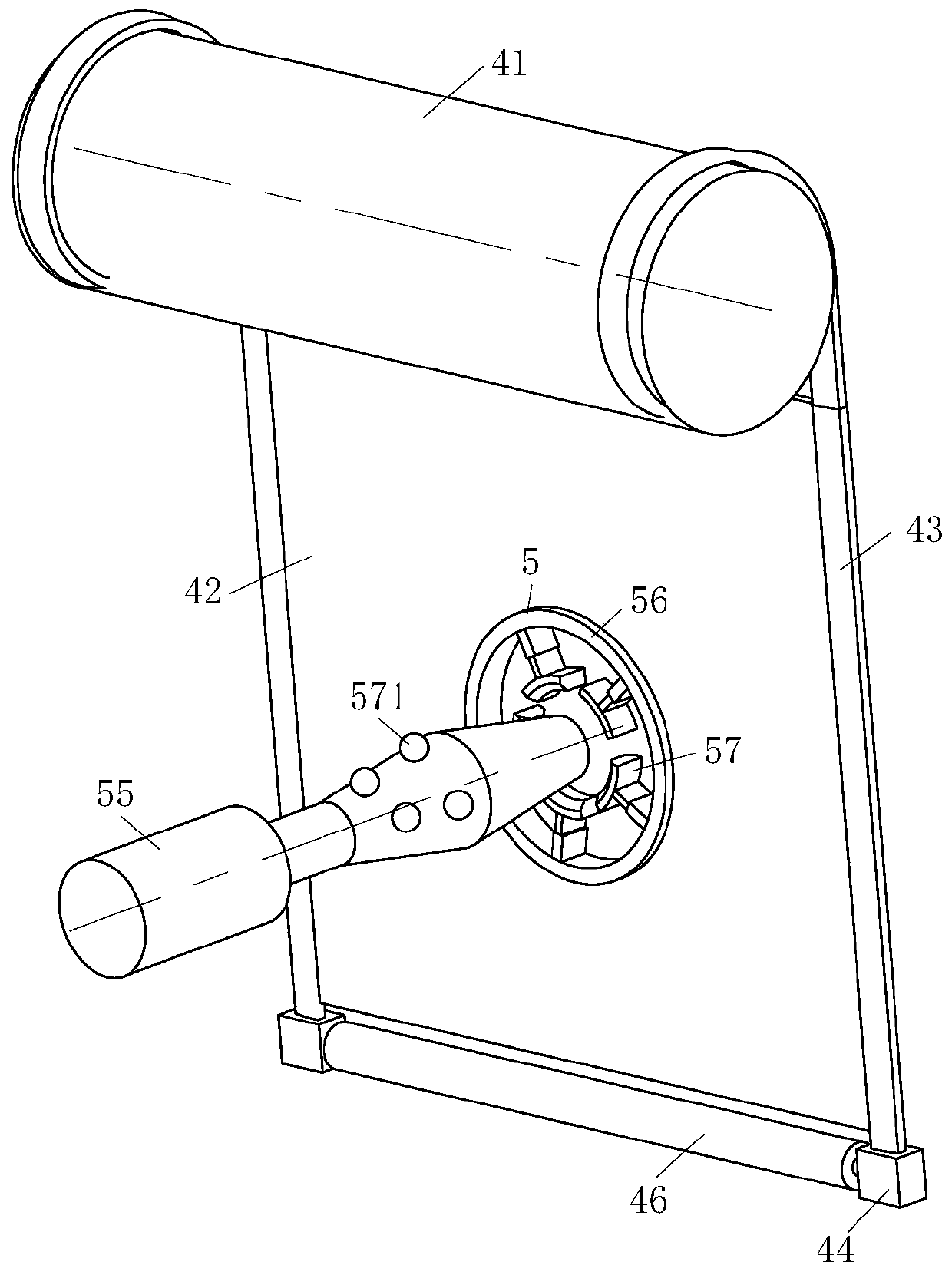

A self-cleaning exhaust fan

ActiveCN108547779BDifficult to clean upEasy to cleanPump componentsPump installationsEngineeringExhaust gas

The invention belongs to the technical field of suction fans and exhaust fans, and particularly relates to a self-cleaning type exhaust fan. The self-cleaning type exhaust fan comprises a shell, an air outlet screen cover, an air inlet screen cover, a motor, fan blades, a scraping module, an impact module and dust discharging modules. The scraping module is connected to one side of the air inlet screen cover in a matched mode, and used for scraping and removing dust on the surface of the air inlet screen cover. The impact module is arranged in the middle of the air inlet screen cover, matchedwith the scraping module and used for beating and removing the dust on the surface of the air inlet screen cover. The first structure of the impact module comprises a support, a first telescopic rod,a first spring, a press block and a sliding ring. The second structure of the impact module comprises a second telescopic rod, a fixing ring, a second spring and arc-shaped plates. The dust discharging modules are arranged on the two sides of the lower end of the air inlet screen cover. According to the self-cleaning type exhaust fan, the impact module is matched with the scraping module to beat and remove the dust on the surface of the air inlet screen cover, the dust discharging modules are arranged to discharge the dust removed by the scraping module and the impact module, and therefore thecleaning effect of the exhaust fan is improved.

Owner:绍兴市侨陆智能科技有限公司

Rice dedusting device and rice dedusting process

ActiveCN106076928BReduce trafficReduce flow rateDirt cleaningCleaning using liquidsThermal sprayingSpiral blade

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

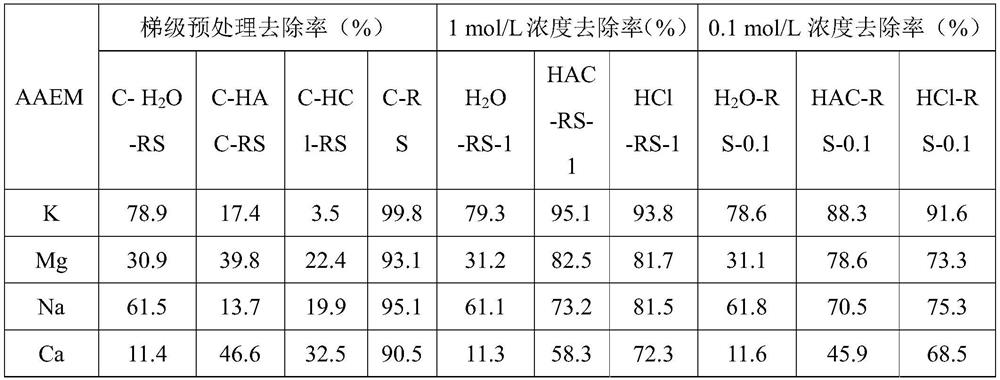

Biomass cascade deashing pretreatment method

The invention discloses a biomass cascade deashing pretreatment method. The biomass cascade deashing pretreatment method comprises the steps that biomass powder is added into water, and stirring and washing are carried out to obtain water-washed biomass powder; the water-washed biomass powder is immersed in an organic acid solution, and stirring and washing are carried out to obtain organic-acid-washed biomass powder; the water-washed and organic-acid-washed biomass powder is immersed in an inorganic acid solution, and stirring and washing are carried out to obtain inorganic-acid-washed biomass powder; and then water-washing, filtering and drying are carried out to obtain cascaded deashing pretreated biomass. The removal rate of ash is higher, sand, stone and metal elements that are easilysoluble in water can be removed, and metals that are insoluble in water can be removed. Compared with a pure inorganic acid washing deashing method, the biomass cascade deashing pretreatment method requires lower acid concentration, is lower in cost of a deashing agent, higher in ash removal rate, more environmentally friendly and lower in equipment loss, and can avoid serious hydrolysis phenomenon of biomass. The advantages of water washing and acid washing are balanced, the concentration required for acid washing is reduced, and the efficiency of ash removal is improved.

Owner:ZHEJIANG FORESTRY UNIVERSITY

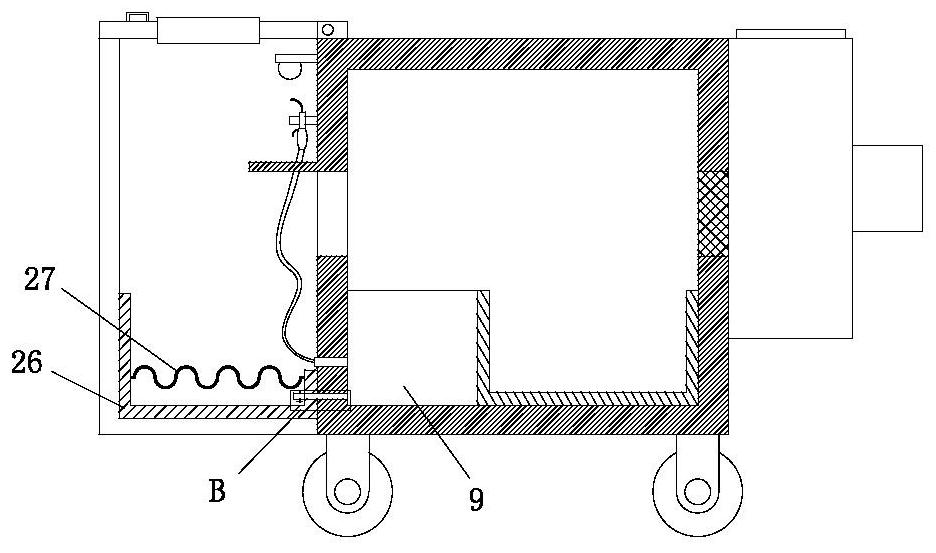

A PC host dust removing box with sufficient dust removing effect

The present invention provides a PC host dust removing box with a sufficient dust removing effect. The PC host dust removing box includes a dust removing box, a dust bin and a compressing blower. Thedust bin is disposed between the dust removing box and the compressing blower and is communicated with the dust removing box and the compressing blower, respectively. The compressing blower is provided with an air outlet. A dust collecting drawer for collecting dust is disposed in the dust bin. A blast blower is further mounted in the dust bin and is provided with a first transmission tube. The first transmission tube is provided with an air hose in a dust removing chamber. The air hose is provided with a pneumatic gun handle. The pneumatic gun handle is equipped with a pneumatic gun hook rail. The pneumatic gun hook rail is equipped with a pneumatic gun sprayer. A pneumatic gun hook rail fixed seat for hanging the pneumatic gun hook rail is mounted on the inner wall of the dust removing box. The dust removing chamber and a dust collecting chamber are communicated via a transmission channel. The dust collecting chamber and the compressing blower are communicated via a filter screen. The PC host dust removing box can efficiently improve dust removing efficiency and quality of the PC host and realize avoiding flying dust during dust removing process.

Owner:国网浙江武义县供电有限公司 +2

A window frame with dust removal function

ActiveCN109162613BEasy to remove dustSimple structureWindow cleanersSpecial door/window arrangementsEngineeringMechanical engineering

Owner:江苏九鼎节能门窗科技有限公司

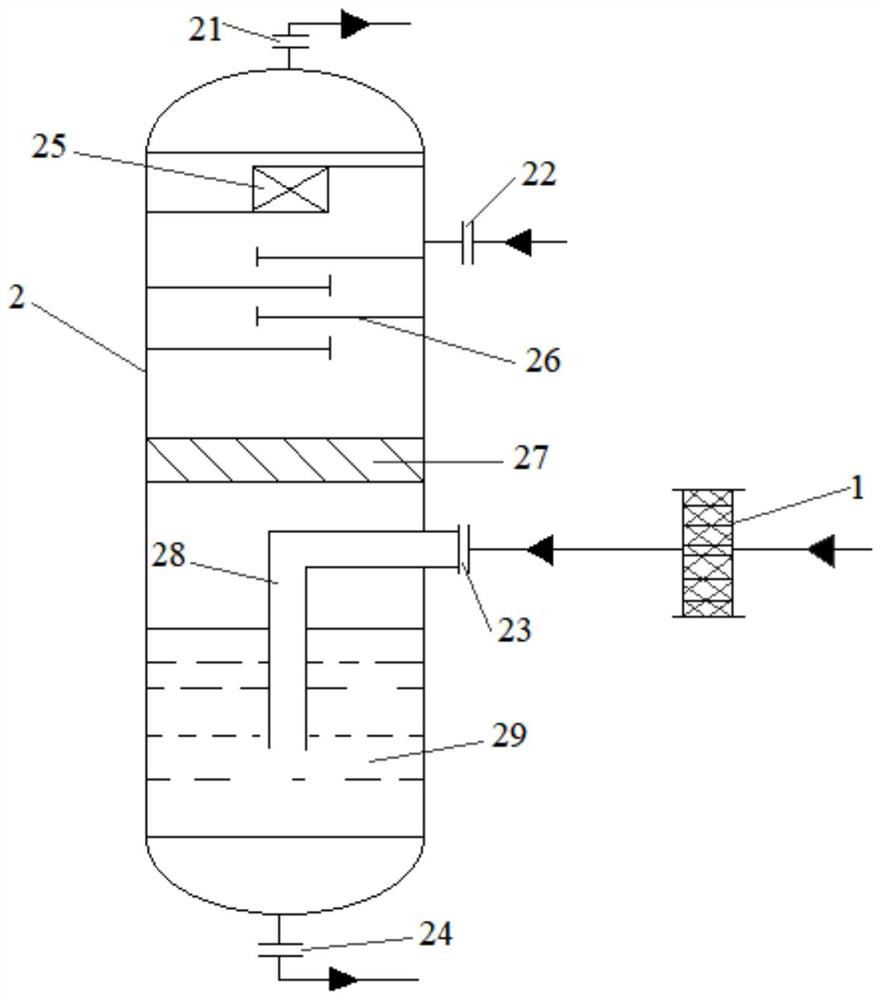

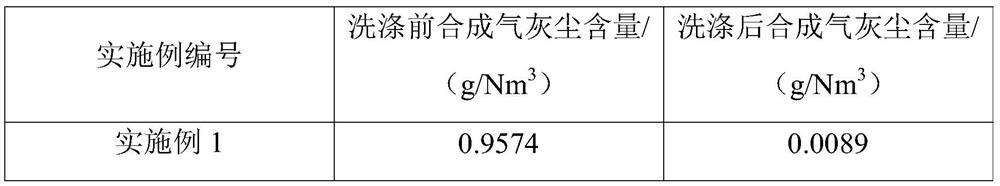

Synthetic gas washing system and washing method

InactiveCN112940796AImprove purification effectImprove ash removal efficiencyGas dust removalSyngasDust control

The invention relates to the technical field of washing, and discloses a synthetic gas washing system and a washing method. The washing system comprises a filter and a washing tower, and a gas outlet of the filter is connected with a gas inlet of the washing tower; and the washing tower is sequentially provided with a gas outlet, a demister, a water inlet, a tower tray, a filler layer, a gas inlet, a water area pool and a water outlet from top to bottom. The method comprises the following steps: synthesis gas is conveyed into a filter for filtering, then is conveyed to a gas inlet of a washing tower, enters a water area pool through a gas inlet pipe of the washing tower for washing and dust removal, then sequentially passes through a filler layer and a tower tray, reversely makes contact with purified water from a water inlet for washing and dust removal, then enters a demister for defoaming, and finally, the gas is discharged from a gas outlet above the demister. The system and the method provided by the invention are used for washing the synthesis gas, have a good dust removal effect and have a better purification effect on the synthesis gas.

Owner:INNER MONGOLIA CHINACOAL YUANXING ENERGY CHEM CO LTD

A special dander suction device for the production of protective clothing

ActiveCN112176689BFlexible removalFlexible cleaningMechanical cleaningPressure cleaningTransmission beltElectric machinery

The invention discloses a hair-absorbing device specially used for producing protective clothing, and relates to the technical field of protective clothing processing. The invention includes a working shell, a rotating shaft is fixed on one side of the working shell, a connecting rod is fixed on the inner ring of the rotating shaft, a fan blade is fixed on one end of the connecting rod, a plurality of first transmission blocks are fixed on the outer side of the connecting rod, and a protective shell is fixed on one side of the working shell. The motor is fixed inside the protective shell, the second transmission block is fixed on the output shaft of the motor, the transmission belt is sleeved on the outside of the first transmission block and the second transmission block, there are installation holes on the first surface of the working shell, and there are ventilation holes on the first surface of the working shell. A mounting block is interferentially connected inside the mounting hole, and a mounting rod is fixed on one side of the mounting block. Through the function of the protective shell, the present invention can flexibly remove the dust on the surface of the protective clothing. Not only the dust removal efficiency is high, but also the dust in the gaps between the cloth of the protective clothing can be removed. Compared with the traditional vacuum cleaner, it is more efficient and designed as The hand-held method can more flexibly clean the details of the protective clothing.

Owner:安徽天元医疗科技有限公司

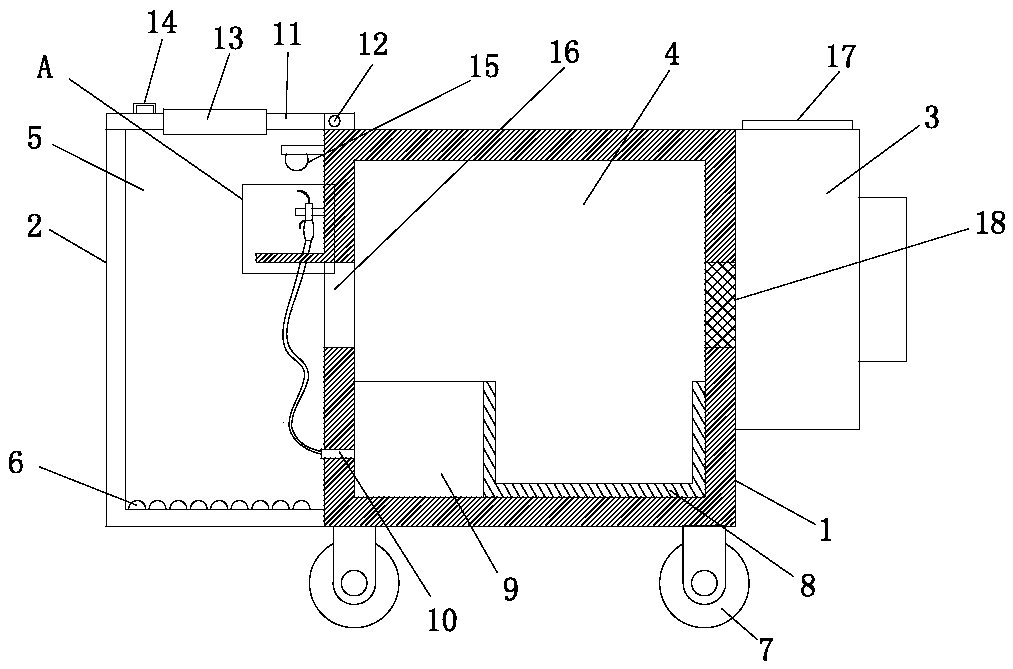

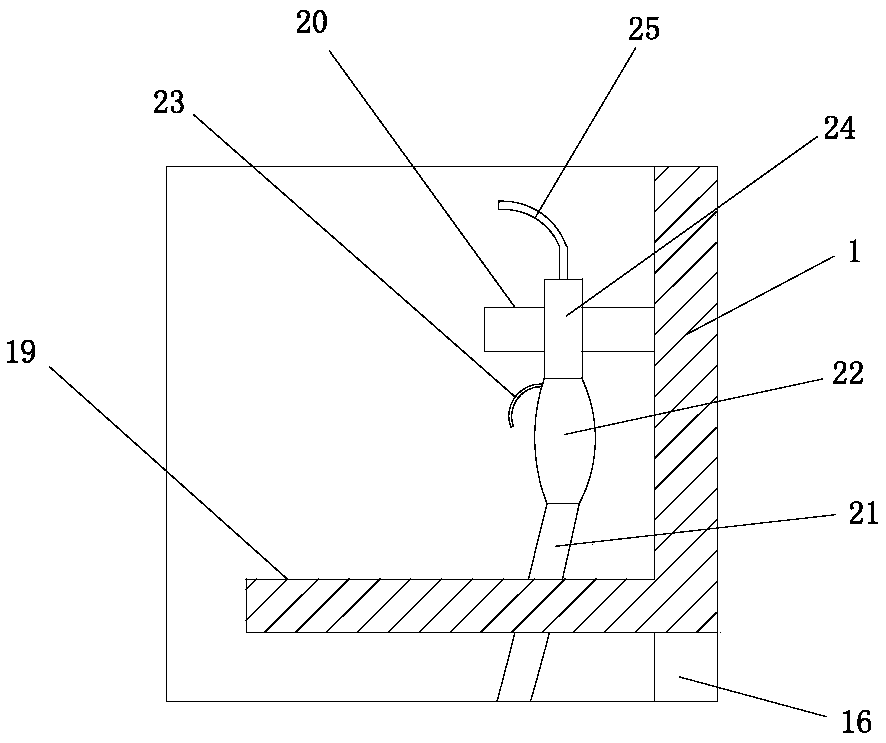

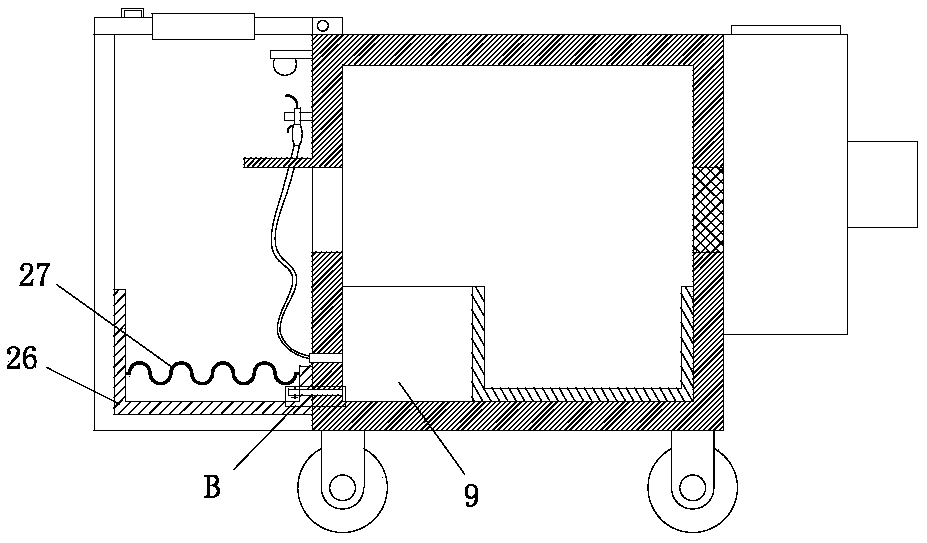

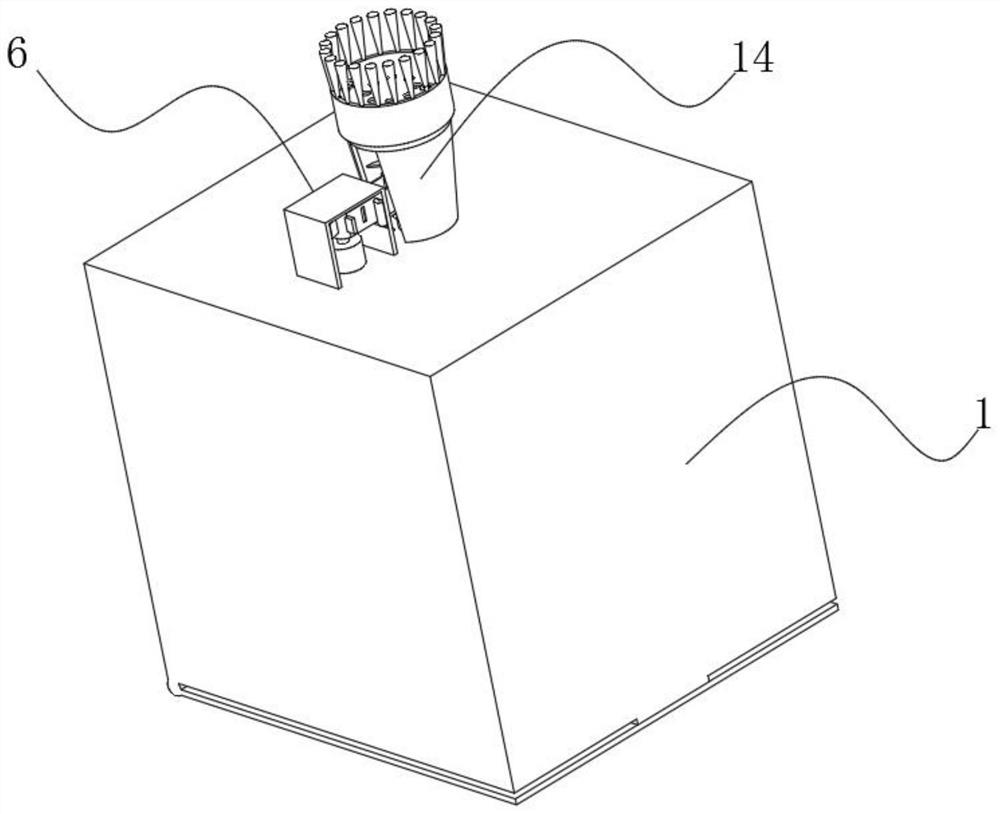

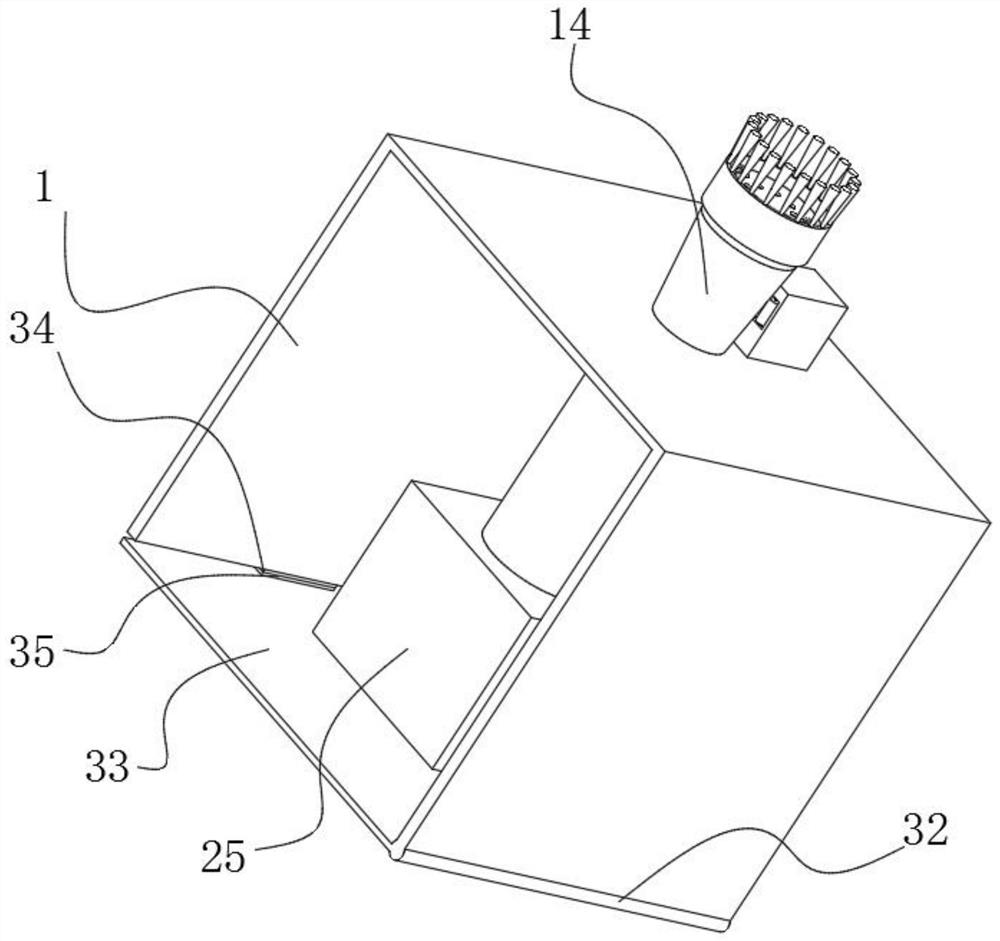

A PC mainframe dust removal box with high dust removal efficiency

ActiveCN109158376BImprove ash removal efficiencyAvoid dustCleaning using gasesDust controlAir blower

Owner:国网浙江武义县供电有限公司 +2

A kind of dedusting equipment and using method for rice finishing

ActiveCN109692722BImprove separation efficiencyReduce process stepsSievingGrain huskingFood safetyIron removal

The invention discloses a dust removal device for rice finishing and a use method thereof, comprising a housing, an agitation device inside the housing and a dust suction device outside the housing. Compared with the prior art, the invention utilizes the opening on the agitation shaft Cooperate with the dust collection device to process the material, the separation efficiency is high, the process steps are reduced, and the ash removal efficiency is improved; compared with the existing process, this process no longer uses the centrifugal principle, which will not increase the generation of broken rice The dry ice cools the material, which weakens the electrostatic adsorption effect, and the dust on the material is easier to grind down after cooling, which improves the dust removal efficiency; the magnet in the inner shell can fully attract the iron filings in the material, ensuring production and food safety, dust removal is more thorough; suitable for all aspects of rice production, a wide range of applications, and can effectively remove iron filings in the middle, iron filings are collected in the inner shell, if there are too many iron filings on the magnet, it will not Dropped into the equipment, the iron removal effect is more obvious.

Owner:江西省李梦粮油有限公司

Hay cutter with dust removal function

InactiveCN112335420AEasy dischargeCompact structureCuttersDirt cleaningAnimal scienceTransmission belt

The invention discloses a hay cutter with a dust removal function. The hay cutter comprises a supporting plate, a hay cutter box body and an air blower; a first baffle and a second baffle are fixedlyinstalled at the two ends of the hay cutter box body correspondingly, and a discharging barrel is installed at the side, away from the hay cutter box body, of the second baffle in a penetrating manner; a feeding cylinder is installed at the upper side of the end, close to the first baffle, of the hay cutter box body in a penetrating manner, the air blower is fixedly installed in the first baffle,a brushing dust removal mechanism is arranged at the bottom between the first baffle and the second baffle, and a transmission belt is arranged in the hay cutter box body; and an auxiliary dust removal and discharging mechanism is arranged at the end, close to the second baffle, in the hay cutter box body. According to the hay cutter, dust accumulated at the bottom in the hay cutter box body is brushed up through the brushing dust removal mechanism, then the brushed dust is blown to the discharging barrel through the air blower, the auxiliary dust removal and discharging mechanism is used in cooperation, so that the dust at the inner side of the discharging barrel is rapidly discharged out of the hay cutter box body, the structure is compact, operation is easy, and the dust removal efficiency is high.

Owner:双峰县湘东机械制造有限责任公司

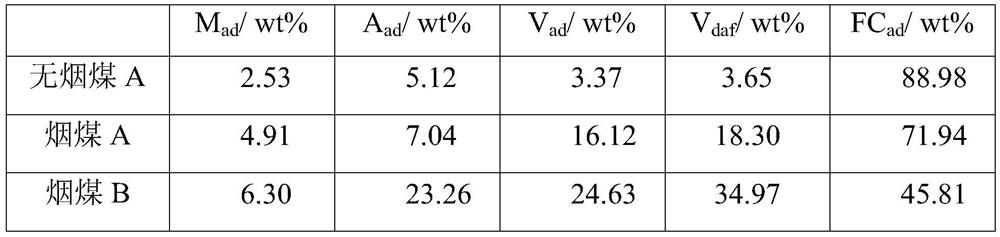

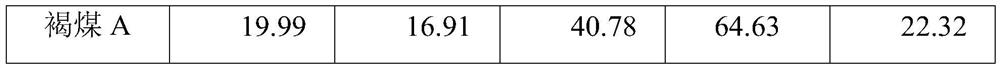

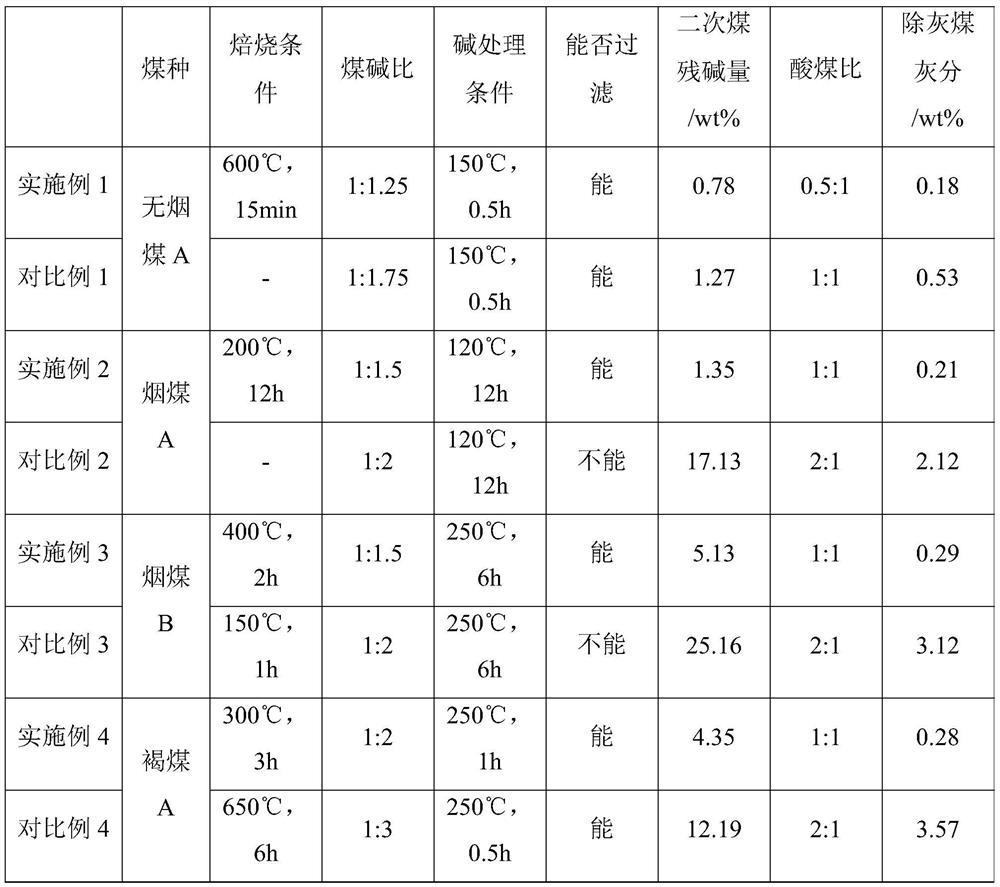

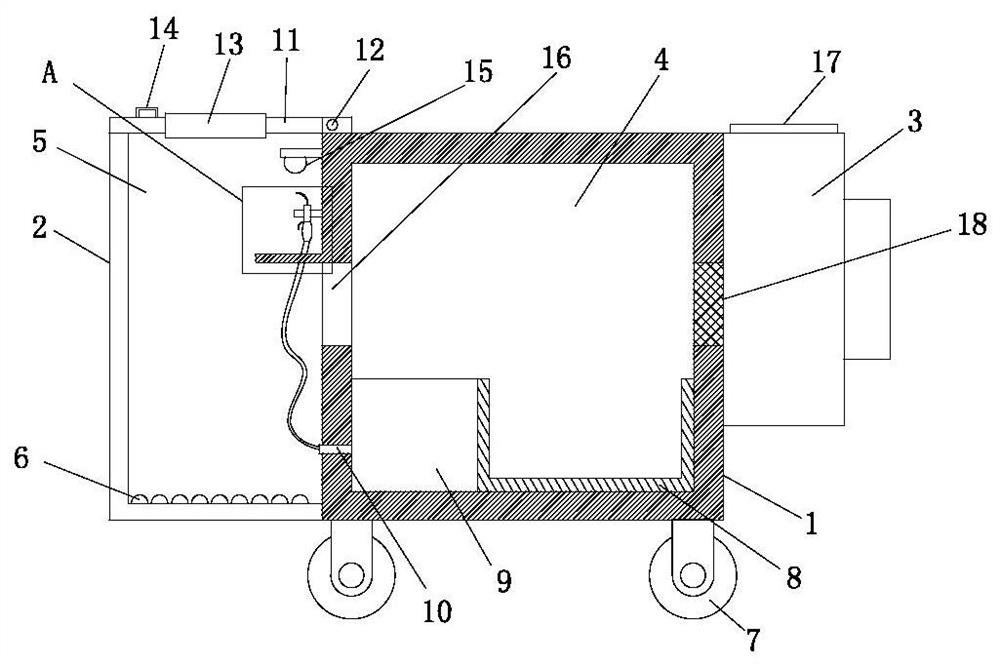

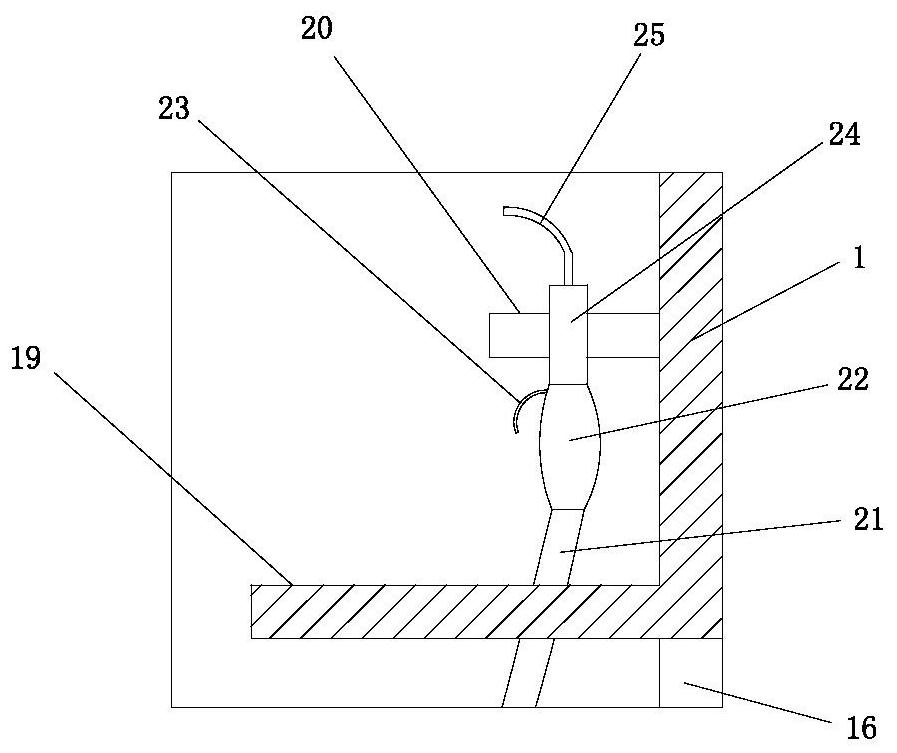

Method for preparing ultra-pure coal

ActiveCN113930268AReduce VOCImprove ash removal efficiencyBiofuelsSolid fuelsCoal chemical industryColloidal particle

The invention relates to the field of coal chemical industry, in particular to a method for preparing ultra-pure coal. The method for preparing the ultra-pure coal comprises the following steps: (1) roasting coal in protective gas; (2) carrying out alkali treatment on the roasted coal to obtain secondary coal; and (3) adding acid into the secondary coal for leaching, and conducting washing and drying to obtain the ultra-pure coal. According to the method, the coal is roasted, so that organic volatile components in the coal can be effectively reduced, the situation that a filtering channel is blocked by colloidal particles is reduced when the coal is treated by a subsequent acid-alkali method, filtering and washing are facilitated, and the content of residual alkali in the secondary coal is greatly reduced. According to the method disclosed by the invention, the ash removal efficiency of the coal, especially the coal with low coalification degree, is improved, the ash content of the obtained ultra-pure coal is less than 0.3 wt%, the use amount of acid and alkali is reduced, and the pollution and comprehensive treatment cost are reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A PC mainframe dust removal box with good dust removal effect

The present invention provides a PC host dust removing box with a sufficient dust removing effect. The PC host dust removing box includes a dust removing box, a dust bin and a compressing blower. Thedust bin is disposed between the dust removing box and the compressing blower and is communicated with the dust removing box and the compressing blower, respectively. The compressing blower is provided with an air outlet. A dust collecting drawer for collecting dust is disposed in the dust bin. A blast blower is further mounted in the dust bin and is provided with a first transmission tube. The first transmission tube is provided with an air hose in a dust removing chamber. The air hose is provided with a pneumatic gun handle. The pneumatic gun handle is equipped with a pneumatic gun hook rail. The pneumatic gun hook rail is equipped with a pneumatic gun sprayer. A pneumatic gun hook rail fixed seat for hanging the pneumatic gun hook rail is mounted on the inner wall of the dust removing box. The dust removing chamber and a dust collecting chamber are communicated via a transmission channel. The dust collecting chamber and the compressing blower are communicated via a filter screen. The PC host dust removing box can efficiently improve dust removing efficiency and quality of the PC host and realize avoiding flying dust during dust removing process.

Owner:国网浙江武义县供电有限公司 +2

Fluorescent lamp tube cleaning device

InactiveCN112006638AProportionally largeAvoid accumulationHousehold cleanersEngineeringTube cleaning

The invention discloses a fluorescent lamp tube cleaning device. The device comprises a mounting block, the mounting block is of a hollow structure, and a through hole is formed in one end of the mounting block; a convex block is arranged on the end surface of one end of the mounting block, and an external thread is arranged on the side wall of the outer side of the convex block; a pulse power supply generator is further arranged in the mounting block; a liquid storage cavity and a sliding cavity are separated in the mounting block through a vertically-arranged partition plate, and the liquidstorage cavity is filled with magnetic fluid; an annular mounting cavity is formed in the side wall of the liquid storage cavity, and an electromagnetic coil is arranged in the annular mounting cavity; and a T-shaped push rod is arranged in the magnetic fluid, the transverse end of the T-shaped push rod is slidably connected with the side wall of the liquid storage cavity, and the initial specificgravity of the T-shaped push rod is larger than the specific gravity of the magnetic fluid. According to the fluorescent lamp tube cleaning device, the tube wall of a fluorescent lamp can be automatically cleaned in the lighting process of the fluorescent lamp, and therefore the lighting effect of the fluorescent lamp tube is continuously guaranteed.

Owner:邓艳丽

Ash removal device for tail flue of fluidized boiler

ActiveCN104613485BEfficient emissionsAchieve separationSolid removalAxial flow pumpsParticulatesExhaust fumes

The invention relates to an ash removing device of the tail flue of a fluidized boiler. The ash removing device comprises a smoke inlet pipe, a cooling pipe, a separation pipe and a sedimentation pipe, wherein the axis of the columnar pipeline of the separation pipe is vertical to the ground, the open end of the columnar pipeline faces to the ground, and the smoke inlet pipe is arranged on the lateral wall of the columnar pipeline; one end of the smoke inlet pipe is communicated with the interior of the columnar pipeline, and the other end thereof is communicated with the tail flue of the fluidized boiler; the cooling pipe is mounted at the sealed end at the top of the separation pipe, the other end of the cooling pipe is communicated with the interior of the separation pipe, and a spraying component is mounted in the cooling pipe; a separator is disposed on the wall face of the separation pipe and comprises a plurality of filter plates, and the filter plates are arranged on the inner wall of the separation pipe in a zigzag and staggered manner; an exhaust pipe is arranged at the bottom of the separation pipe. The ash removing device has the advantages that smoke is absorbed through water, and separation of waste gas, particles and soluble impurities is achieved by the filtering separation mechanism.

Owner:BRIGHT THERMAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com