Efficient environmental-protection aluminum alloy alkali ash removing method

An environmentally friendly, aluminum alloy technology, used in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of reducing the service life of the oxidation tank, easy to pollute the oxidation tank, poor environmental protection, etc., and achieve stable ash removal effect. , The effect of reducing production cost and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Taking 2024 aluminum alloy as an example, an efficient and environmentally friendly method for removing soda ash on the surface of 2024 aluminum alloy profiles includes the following steps:

[0028] A. Billet racking: put the aluminum alloy profiles on the racks according to the requirements of anodized material loading to ensure that the aluminum alloy profiles are well conductive;

[0029] B. Sulfuric acid degreasing: immerse the aluminum alloy profile in 180-220g / L sulfuric acid solution for 1-3 minutes and take it out;

[0030] C. Alkaline etching: immerse the aluminum alloy profile after sulfuric acid degreasing in 50-80g / L sodium hydroxide solution for 10-60s, and the immersion temperature is 50-60°C;

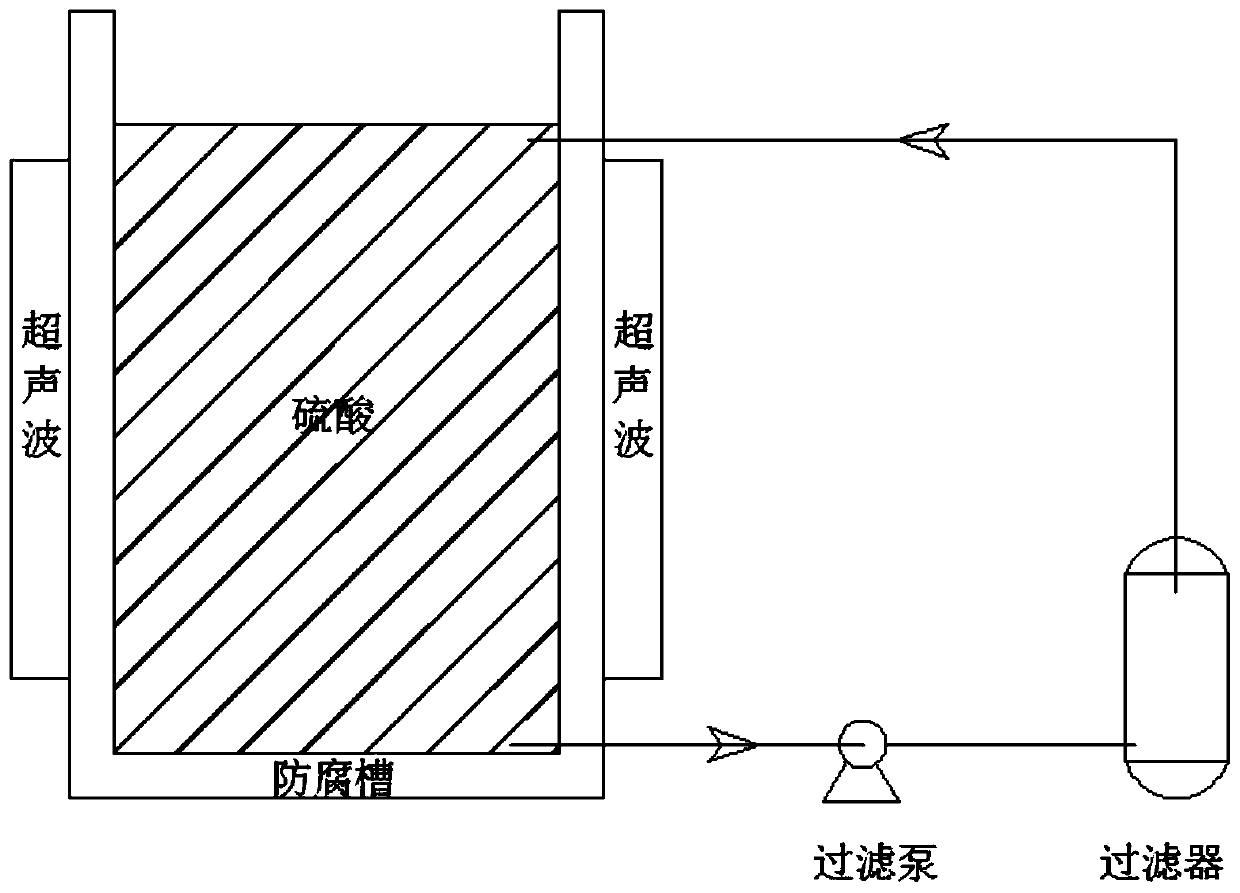

[0031] D. Ash removal: place the aluminum alloy profile after alkali etching in an anticorrosion tank with 120-160g / L sulfuric acid solution and immerse for 30-90s. The anticorrosion tank is placed in an ultrasonic vibrator, which is connected with a filter in sequ...

Embodiment 2

[0035] Taking 7015 aluminum alloy as an example, an efficient and environmentally friendly method for removing soda ash on the surface of 7015 aluminum alloy profiles includes the following steps:

[0036] A. Billet racking: put the aluminum alloy profiles on the racks according to the requirements of anodized material loading to ensure that the aluminum alloy profiles are well conductive;

[0037] B. Sulfuric acid degreasing: immerse the aluminum alloy profile in 180-220g / L sulfuric acid solution for 1-3 minutes and take it out;

[0038] C. Alkaline etching: immerse the aluminum alloy profile after sulfuric acid degreasing in 50-80g / L sodium hydroxide solution for 10-60s, and the immersion temperature is 50-60°C;

[0039] D. Ash removal: Place the aluminum alloy profiles after alkali etching in an anti-corrosion tank with 160-220g / L sulfuric acid solution and immerse them for 10-60s. The anti-corrosion tank is placed in an ultrasonic vibrator, which is connected with a filter...

Embodiment 3

[0043] Taking die-casting aluminum parts as an example, an efficient and environmentally friendly method for removing soda ash on the surface of die-casting aluminum parts includes the following steps:

[0044] A. Billet racking: put the aluminum alloy profiles on the racks according to the requirements of anodized material loading to ensure that the aluminum alloy profiles are well conductive;

[0045] B. Sulfuric acid degreasing: immerse the aluminum alloy profile in 180-220g / L sulfuric acid solution for 1-3 minutes and take it out;

[0046] C. Alkaline etching: immerse the aluminum alloy profile after sulfuric acid degreasing in 50-80g / L sodium hydroxide solution for 10-60s, and the immersion temperature is 50-60°C;

[0047] D. Ash removal: place the aluminum alloy profile after alkali etching in an anti-corrosion tank with 160-220g / L sulfuric acid solution and immerse it for 10-120s. The anti-corrosion tank is placed in an ultrasonic vibrator, which is connected with a fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com