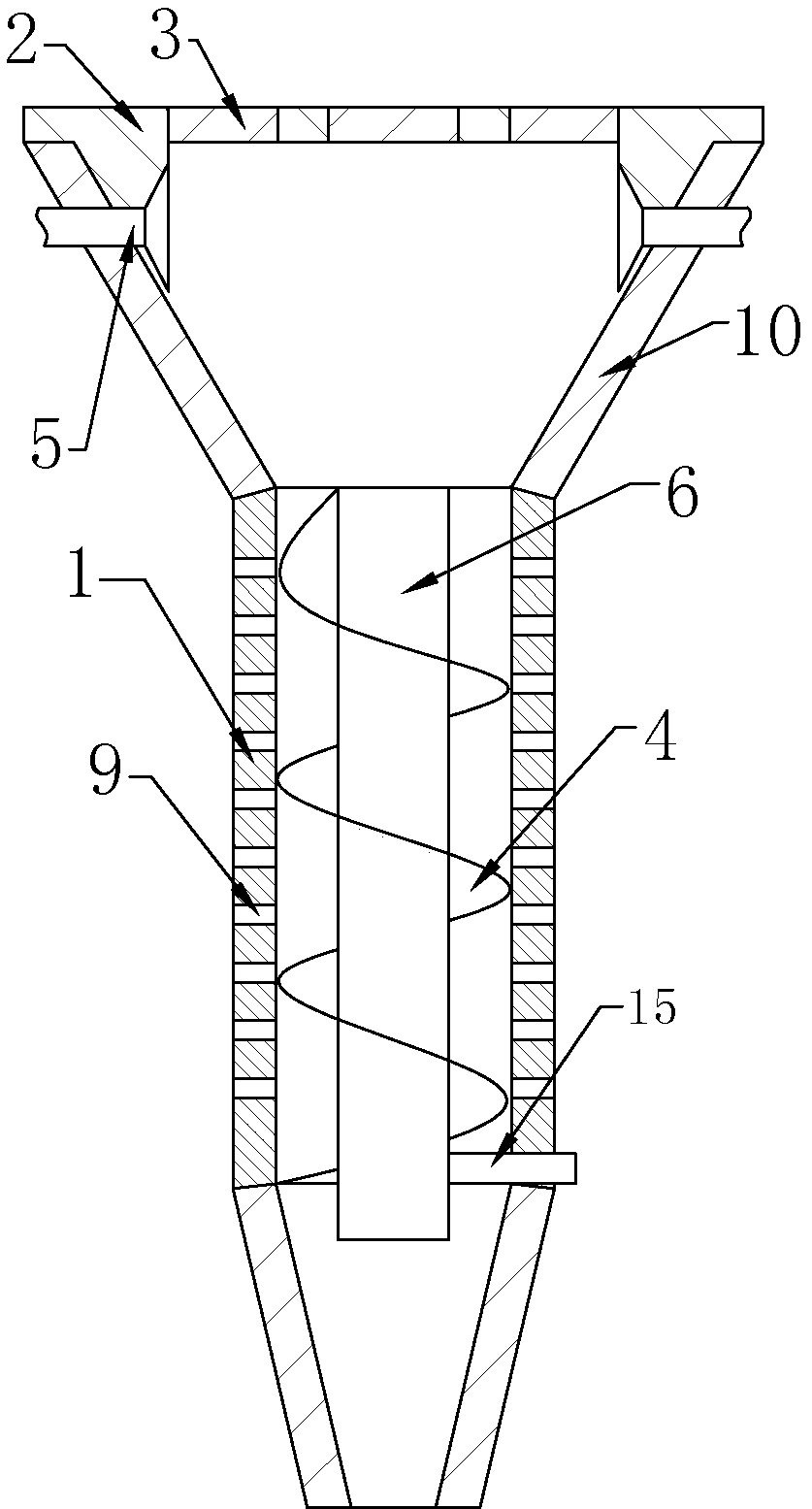

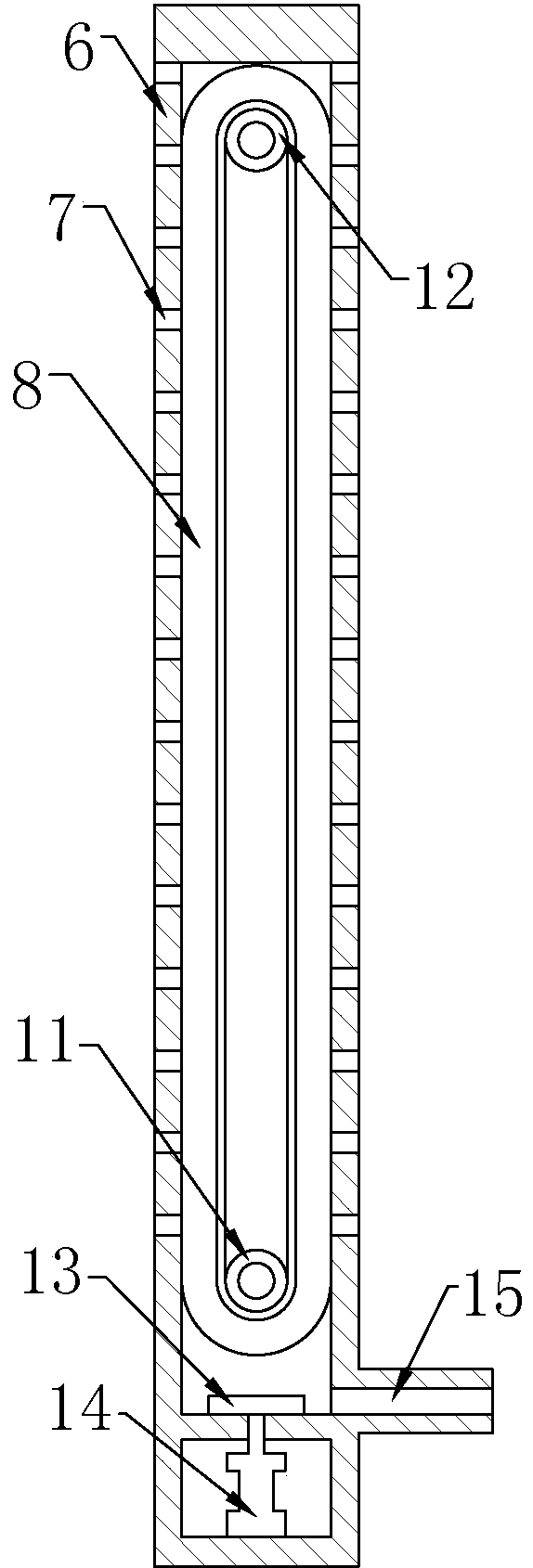

Rice dedusting device and rice dedusting process

A technology of dust removal device and processing technology, which is applied in the fields of removing smoke and dust, grain processing, chemical instruments and methods, etc., can solve the problems such as the inability of regular and uniform distribution of rice, affecting the work efficiency, and the inability to continuously remove ash in the inner cylinder, so as to improve the Dust removal efficiency, ensure dust removal effect, ensure the effect of particle quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0033] Embodiment two: on the basis of embodiment one, its difference is, rice dedusting process, comprises the following steps:

[0034] A, send rice: use the belt conveyor that the rotating speed is 140r / min to send the finished rice into the upper cylinder 10;

[0035] B. Loose rice: When the rice enters the upper cylinder 10, it needs to pass through the rice dispersing plate 2, and the rice enters the rice inlet hole. The rice will be in contact with the bar plate 3 with 20 grids, and the bar plate 3 will hold the rice. Divided into multiple sub-flows, the sub-flows increase the contact area of the rice with the air, and the hindrance of the bar plate 3 will increase the distance between the rice grains when they fall;

[0036] C. Water spraying and dedusting: After the rice has passed through the step of loosening rice, start the water spray pipe 5, the flow rate of water is 0.7L / s, the water spray pipe 5 sprays water into the atomizing nozzle, and the atomizing nozzle...

Embodiment 3

[0038] Embodiment three: on the basis of embodiment one, its difference is, rice dedusting process, comprises the following steps:

[0039] A. Sending rice: use the belt conveyor with a rotating speed of 85r / min to send the finished rice into the upper cylinder 10;

[0040] B. Loose rice: When the rice enters the upper cylinder 10, it needs to pass through the rice-loosening disc 2, and the rice enters the rice inlet hole. The rice will be in contact with the stopper disc 3 with 16 grids, and the stopper disc 3 will hold the rice Divided into multiple sub-flows, the sub-flows increase the contact area of the rice with the air, and the hindrance of the bar plate 3 will increase the distance between the rice grains when they fall;

[0041] C. Water spraying and dedusting: after the rice has gone through the step of loosening rice, start the water spray pipe 5, the flow rate of water is 0.5L / s, the water spray pipe 5 sprays water into the atomizing nozzle, and the atomizing noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com