Method for preparing ultra-pure coal

A coal and sub-coal technology, applied in the field of coal chemical industry, can solve the problems of high residual alkali and difficulty in slurry filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

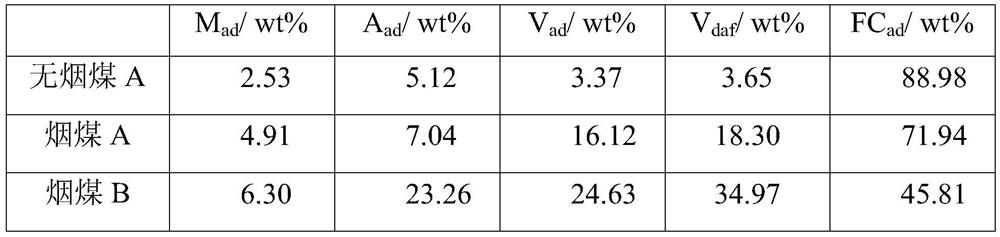

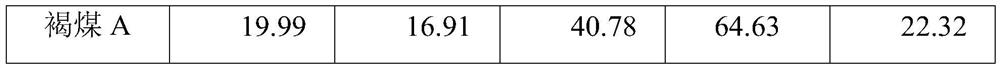

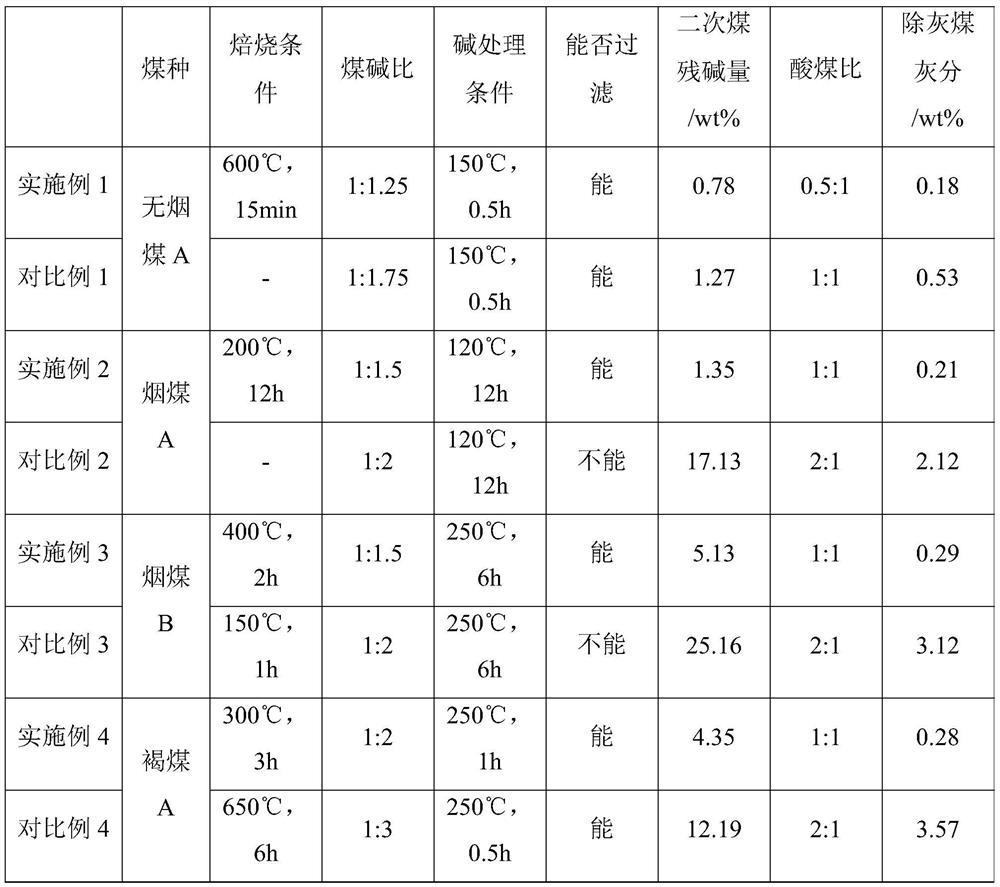

Examples

Embodiment 1

[0034] A method for preparing ultra-pure coal, the steps are as follows:

[0035] (1) Crushing the anthracite coal A to a particle size <6mm, and then roasting at 600°C for 15 minutes with nitrogen;

[0036] (2) Take 400g of roasted anthracite coal A (broken to a particle size <1mm) and 500g of sodium hydroxide, mix with 400ml of water, knead and react at 150°C for 0.5h, after cooling, add 1L of water to dilute, filter and wash 3 times, Obtaining a secondary coal filter cake with an alkali content of 0.78wt%;

[0037] (3) Add 10wt% dilute hydrochloric acid to the secondary coal filter cake according to the acid-coal ratio of 0.5:1, leach for 60min at 60°C, filter and wash and dry the filter cake to obtain ultra-pure coal with an ash content of 0.18wt%. As shown in table 2.

Embodiment 2

[0043] A method for preparing ultra-pure coal, the steps are as follows:

[0044] (1) Break the bituminous coal A to <3mm, and then roast it under nitrogen at 200°C for 12 hours;

[0045] (2) Take 100g of roasted bituminous coal A (broken to particle size <1mm), mix with 150g of potassium hydroxide and 850ml of water, stir and react at 120°C for 12h, filter after cooling, then add 1000ml of water to wash 3 times, and dry to obtain A secondary coal filter cake with an alkali content of 1.35wt%;

[0046] (3) Add 20wt% dilute sulfuric acid to the secondary coal filter cake according to the acid-coal ratio of 1:1, leach for 60min at 60°C, filter and wash the filter cake, and dry the filter cake to obtain ultra-pure coal with an ash content of 0.21wt%. As shown in table 2.

Embodiment 3

[0052] A method for preparing ultra-pure coal, the steps are as follows:

[0053] (1) Break the bituminous coal B to <1mm, and then roast it under nitrogen at 400°C for 2 hours;

[0054] (2) Take 100g of roasted bituminous coal B (broken to a particle size <1mm), mix it with 150g of sodium hydroxide and 850ml of water, stir and react at 250°C for 6h, filter after cooling, and then add 1000ml of water to wash 3 times to obtain the alkali content 5.13wt% secondary coal filter cake;

[0055] (3) Add 5wt% dilute nitric acid to the secondary coal filter cake according to the acid-coal ratio of 1:1, leach for 60min at 60°C, filter and wash the filter cake, and dry the filter cake to obtain ultra-pure coal with an ash content of 0.29wt%. As shown in table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com