Antibacterial PVC artificial leather and preparation method thereof

A technology of artificial leather and antibacterial powder, which is applied in the direction of textiles, papermaking, building components, etc., can solve the problems of poor air permeability, poor comprehensive mechanical properties, easy peeling of base fabric and coating, high organic volatilization, etc., and achieve peel strength High, saving manpower and equipment costs, strong antibacterial durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

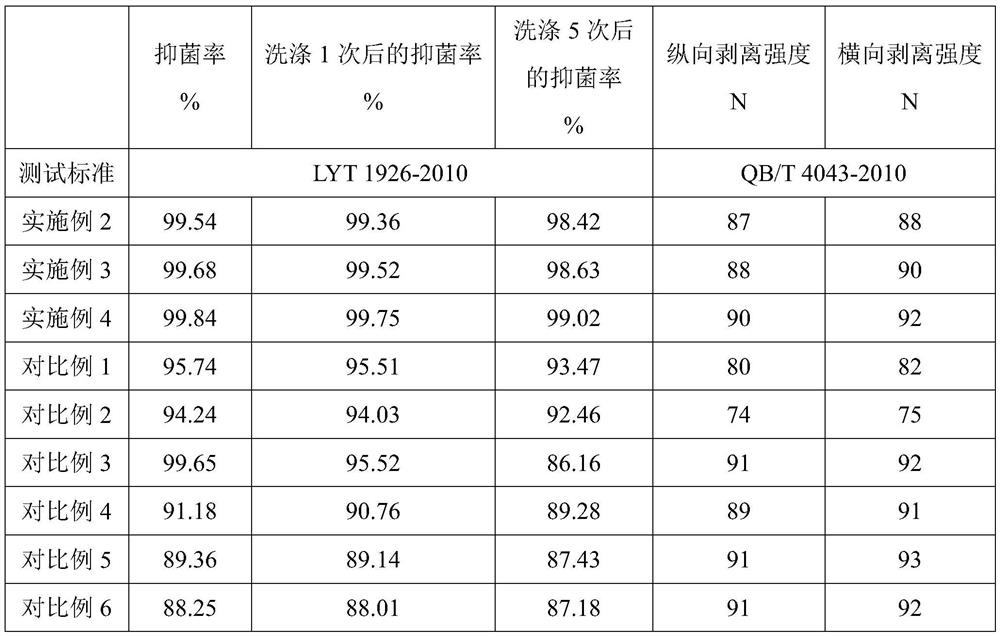

Examples

Embodiment 1

[0065] An antibacterial PVC artificial leather, the antibacterial PVC artificial leather includes a base cloth layer, the base cloth layer is sequentially provided with coating one and coating two;

[0066] Described coating one is made from the raw material that comprises following weight part:

[0067] 75-85 parts of polyvinyl chloride resin powder,

[0068] 6-9 parts of ethylene-vinyl acetate copolymer powder,

[0069] 2.6-3.2 parts of calcium salt of sulfonated naphthenate,

[0070] 3-5 parts of expanded perlite powder,

[0071] The second coating is made of raw materials comprising the following parts by weight:

[0072] 70-80 parts of polyvinyl chloride resin powder,

[0073] 10-14 parts of ethylene-vinyl acetate copolymer powder,

[0074] 2.4-3 parts of calcium salt of sulfonated naphthenate,

[0075] 1.6-2 parts of isopropyl 3,4-diethoxyphenylcarbamate,

[0076] 2 to 2.5 parts of graphene oxide,

[0077] 2.2-2.7 parts of silver ion antibacterial powder,

[0078]...

Embodiment 2

[0110] An antibacterial PVC artificial leather, the antibacterial PVC artificial leather includes a base cloth layer, the base cloth layer is sequentially provided with coating one and coating two;

[0111] Described coating one is made from the raw material that comprises following weight part:

[0112] 75 parts of polyvinyl chloride resin powder,

[0113] 6 parts of ethylene-vinyl acetate copolymer powder,

[0114] 2.6 parts of calcium salt of sulfonated naphthenate,

[0115] 3 parts expanded perlite powder,

[0116] The second coating is made of raw materials comprising the following parts by weight:

[0117] 70 parts of polyvinyl chloride resin powder,

[0118] 10 parts of ethylene-vinyl acetate copolymer powder,

[0119] 2.4 parts of calcium salt of sulfonated naphthenate,

[0120] 1.6 parts of isopropyl 3,4-diethoxyphenylcarbamate,

[0121] 2 parts of graphene oxide,

[0122] Silver ion antibacterial powder 2.2 parts,

[0123] 5 parts of expanded perlite powder,...

Embodiment 3

[0140] An antibacterial PVC artificial leather, the antibacterial PVC artificial leather includes a base cloth layer, the base cloth layer is sequentially provided with coating one and coating two;

[0141] Described coating one is made from the raw material that comprises following weight part:

[0142] 85 parts of polyvinyl chloride resin powder,

[0143] 9 parts of ethylene-vinyl acetate copolymer powder,

[0144] 3.2 parts of calcium salt of sulfonated naphthenate,

[0145] 5 parts of expanded perlite powder,

[0146] The second coating is made of raw materials comprising the following parts by weight:

[0147] 80 parts of polyvinyl chloride resin powder,

[0148] 14 parts of ethylene-vinyl acetate copolymer powder,

[0149] 3 parts of calcium salt of sulfonated naphthenate,

[0150] 2 parts of isopropyl 3,4-diethoxyphenylcarbamate,

[0151] 2.5 parts of graphene oxide,

[0152] Silver ion antibacterial powder 2.7 parts,

[0153] 7 parts of expanded perlite powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com