Downward-drive type device for removing dust on inner surface of steel pipe

A steel pipe and turntable technology, applied in the field of steel pipe manufacturing, can solve the problems of large floor space, huge ash removal mechanism, low efficiency, etc., and achieve the effect of improving production efficiency and reducing preparation and auxiliary time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will further explain the down-drive type steel pipe inner surface ash removal device according to the present invention according to the specific implementation method and the accompanying drawings, but the explanation does not constitute an improper limitation of the present invention.

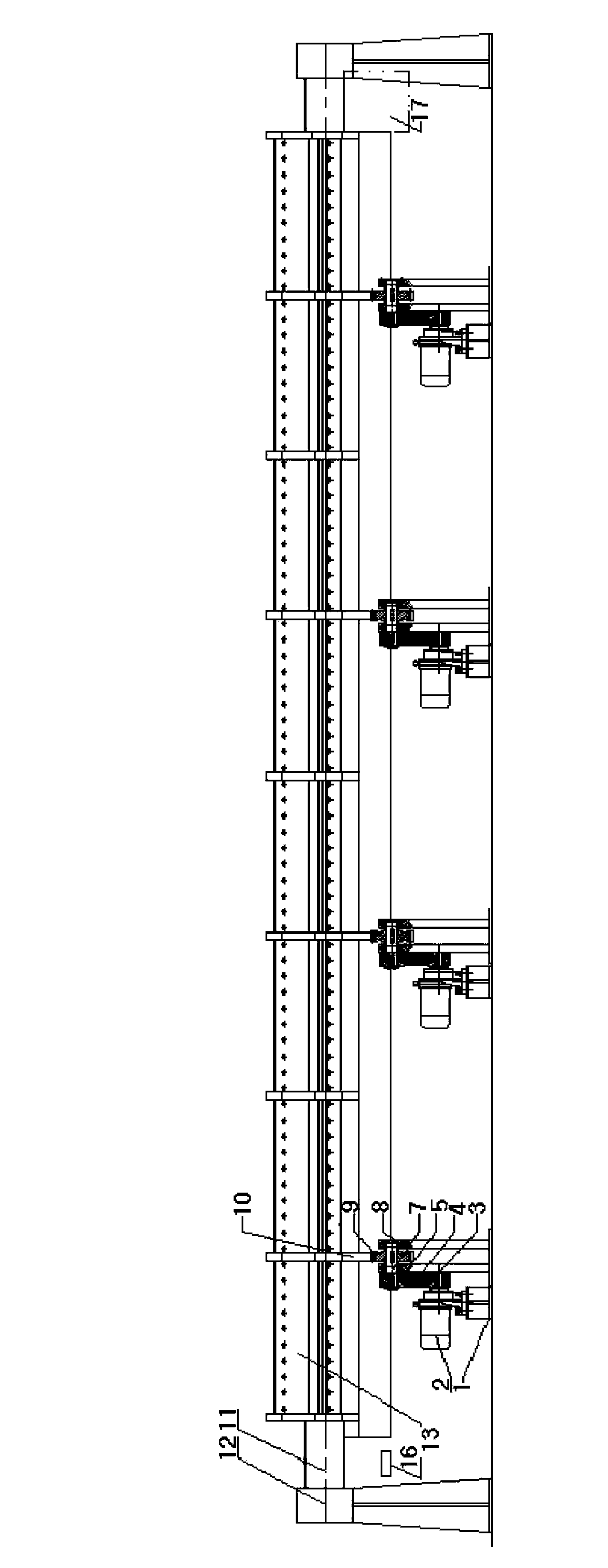

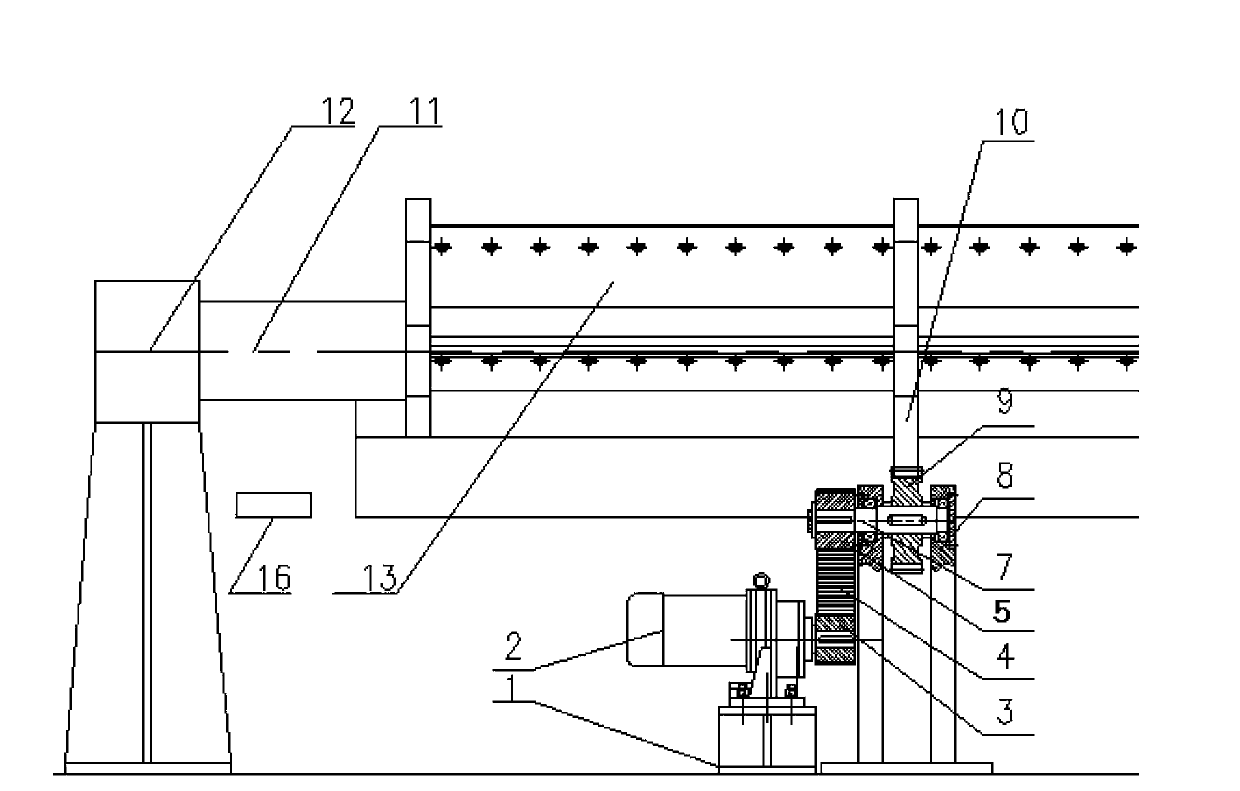

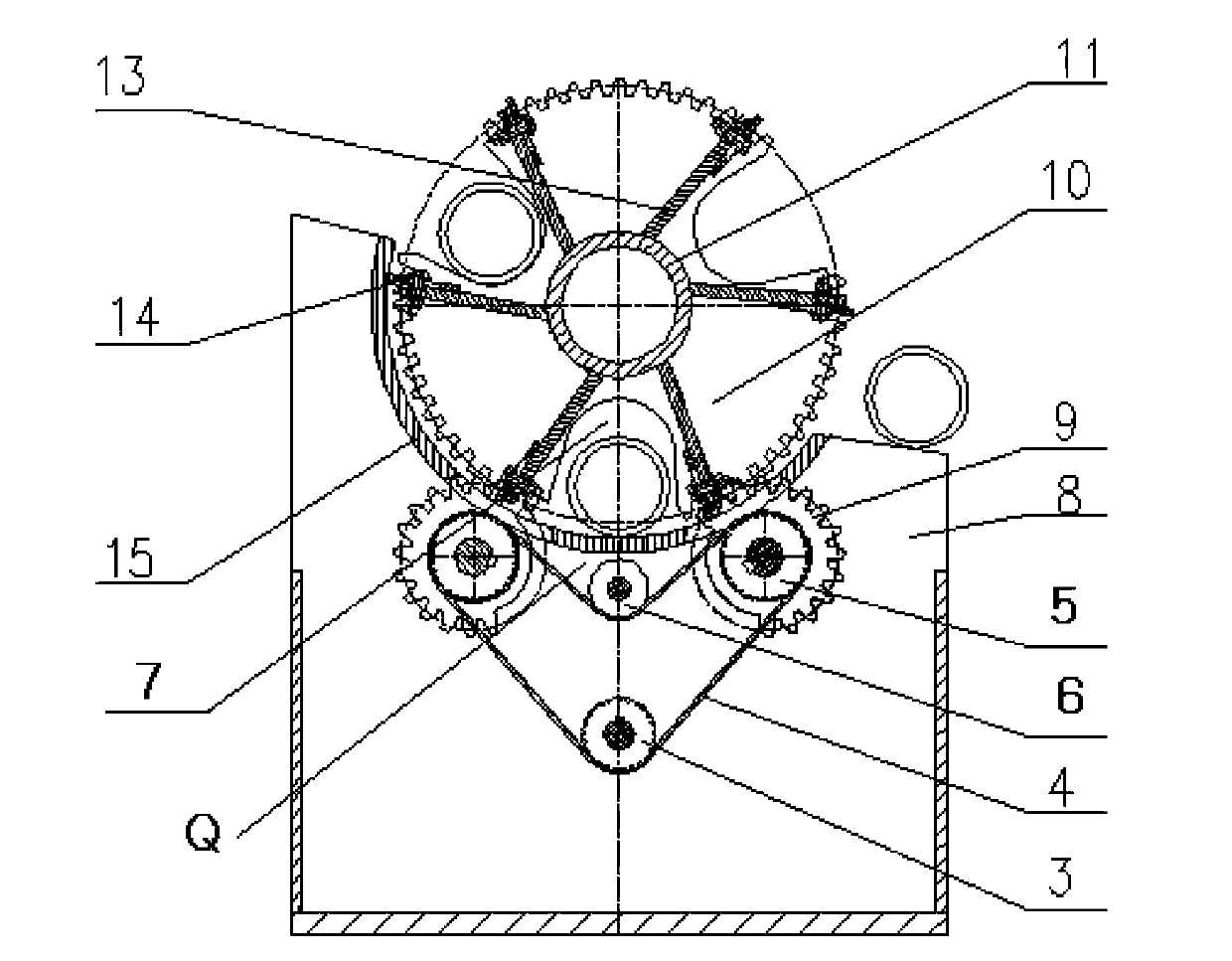

[0039] Such as Figure 1 to Figure 3 As shown, in this embodiment, the down-drive type steel pipe inner surface ash removal device includes: an air nozzle 16 at one end of the steel pipe and an air suction chamber 17 at the other end of the steel pipe, and the distance between the air nozzle 16 and the air suction chamber 17 is slightly larger than required The maximum length of the steel pipe for ash removal treatment, the air nozzle 16 and the suction chamber 17 are set at the ash removal position Q; The two ends of the multi-station turntable 10 are supported by bearings and the shaft seat 12, and three U-shaped gaps are uniformly opened on the circumference of each mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com