A self-cleaning exhaust fan

An exhaust fan and self-cleaning technology, which is applied in the direction of mechanical equipment, non-variable pumps, machines/engines, etc., can solve problems such as difficult cleaning, achieve the effect of preventing secondary pollution and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

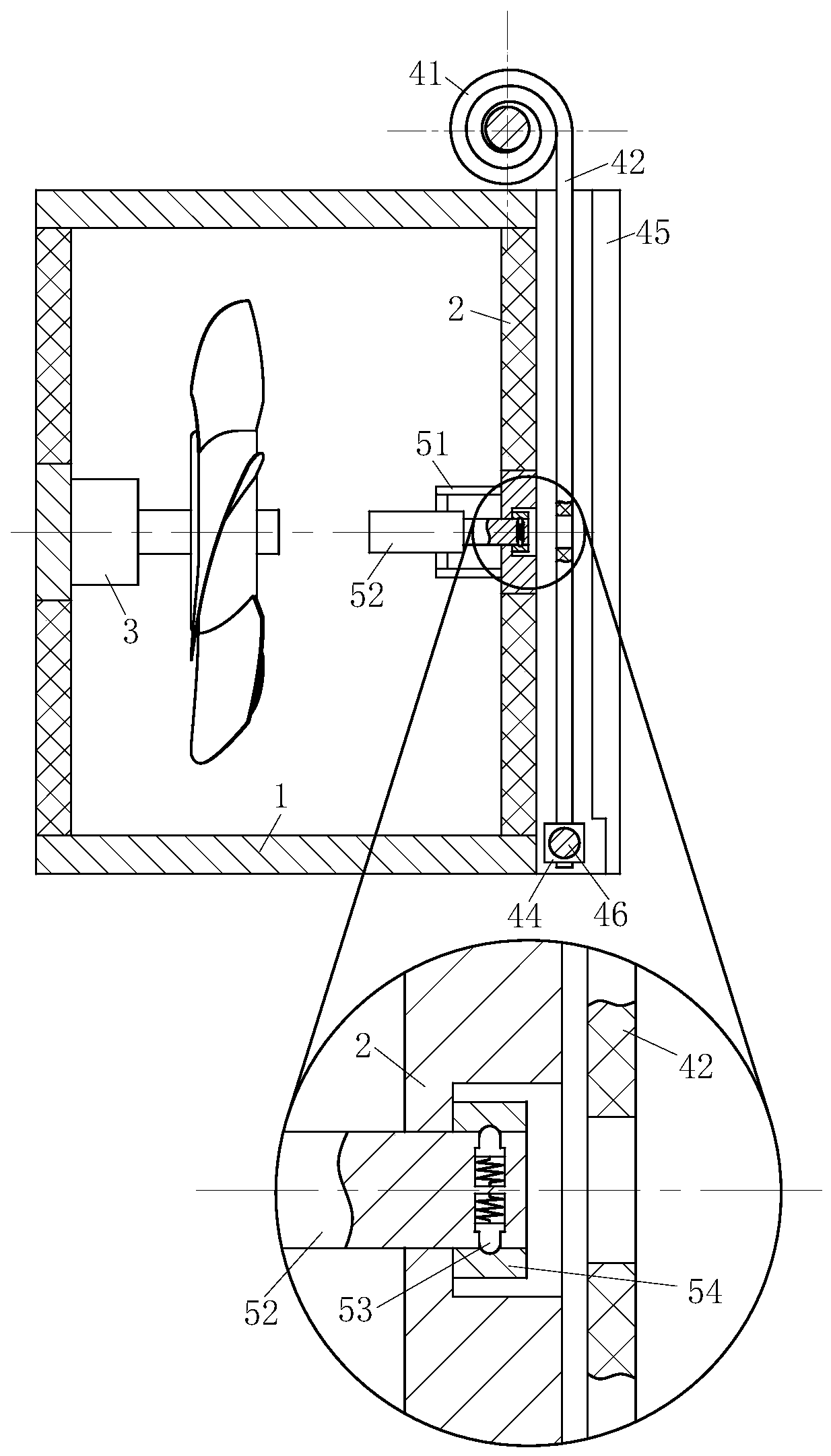

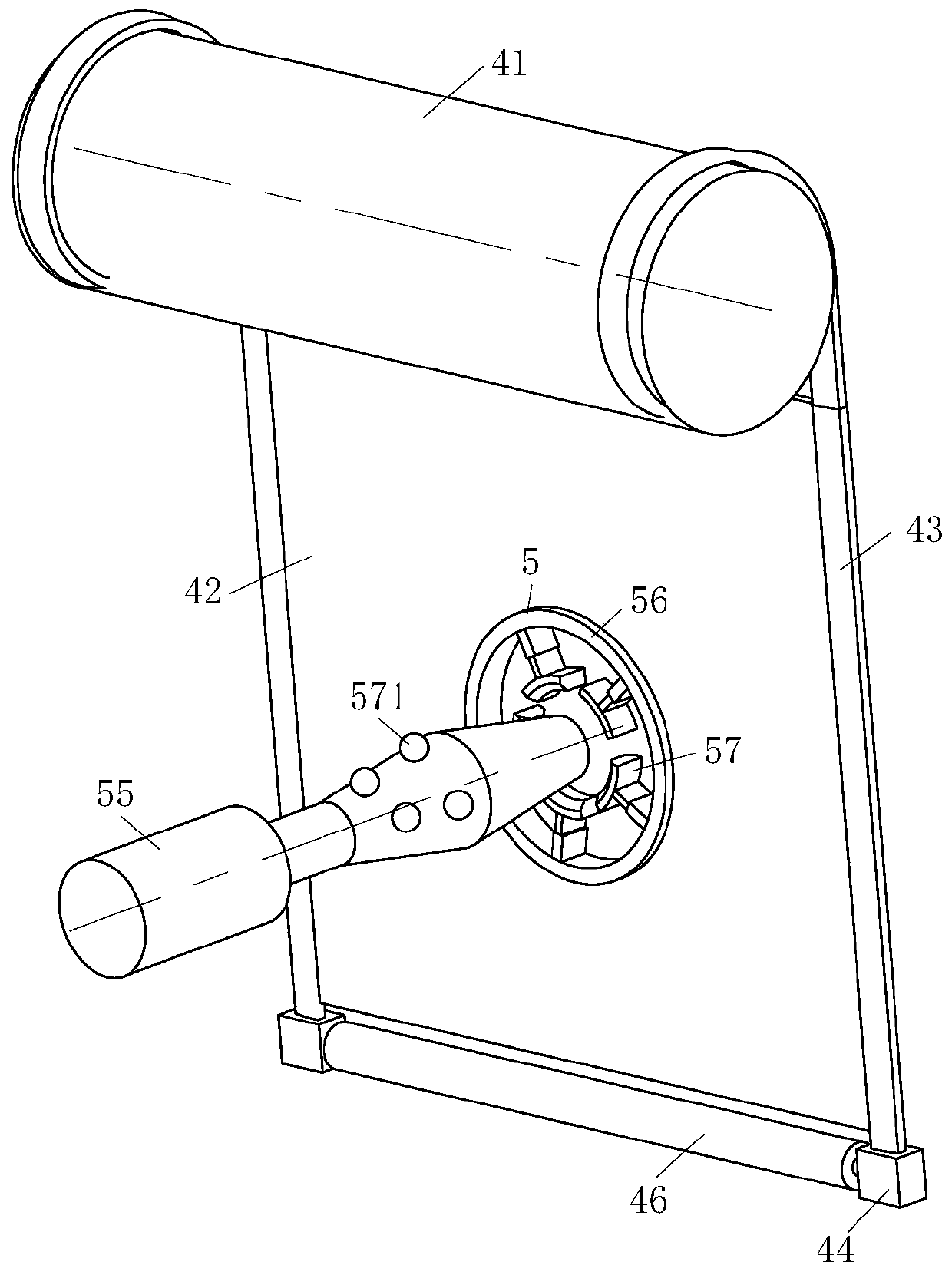

[0028] As an embodiment of the present invention, the inner arc surface of the arc-shaped plate 57 is provided with a chamfer corresponding to the conical surface of the second telescopic rod 55; A group of balls 571 is used to reduce the friction force between the arc plate 57 and the second telescopic rod 55 when the elastic film 42 rebounds, to increase the slapping force, and to shake off the dirt attached to the air inlet net cover 2; to improve the cleaning effect of the exhaust fan .

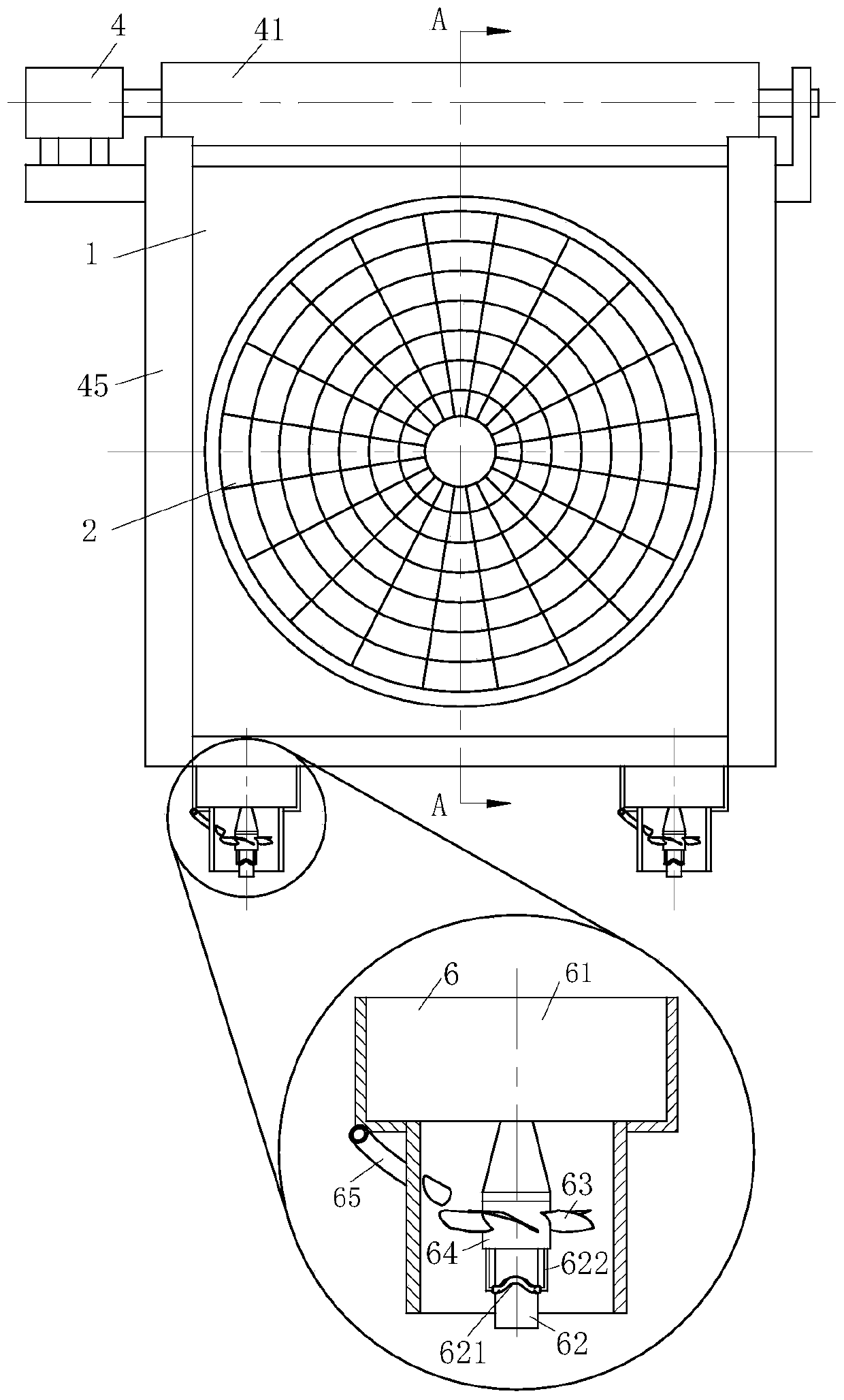

[0029] As an embodiment of the present invention, the ash discharge module 6 includes an ash discharge pipe 61, a fixed shaft 62, a blade 63, a ferrule 64 and an air intake pipe 65; Below; the middle part of the ash discharge pipe 61 is provided with a fixed shaft 62; the blade 63 is rotated and mounted on the outer ring of the fixed shaft 62 through a ferrule 64; the air inlet pipe 65 is arranged on the outer ring of the ash discharge pipe 61 with a spiral slope downward; The air intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com