Small equipment for removing stone ballast below railway sleeper

A technology of small equipment and railway track, applied in the direction of road, track, track superstructure, etc., can solve the problems of high cost, inconvenient for workers to operate, and lack of versatility, etc., and achieve the effect of low cost, easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

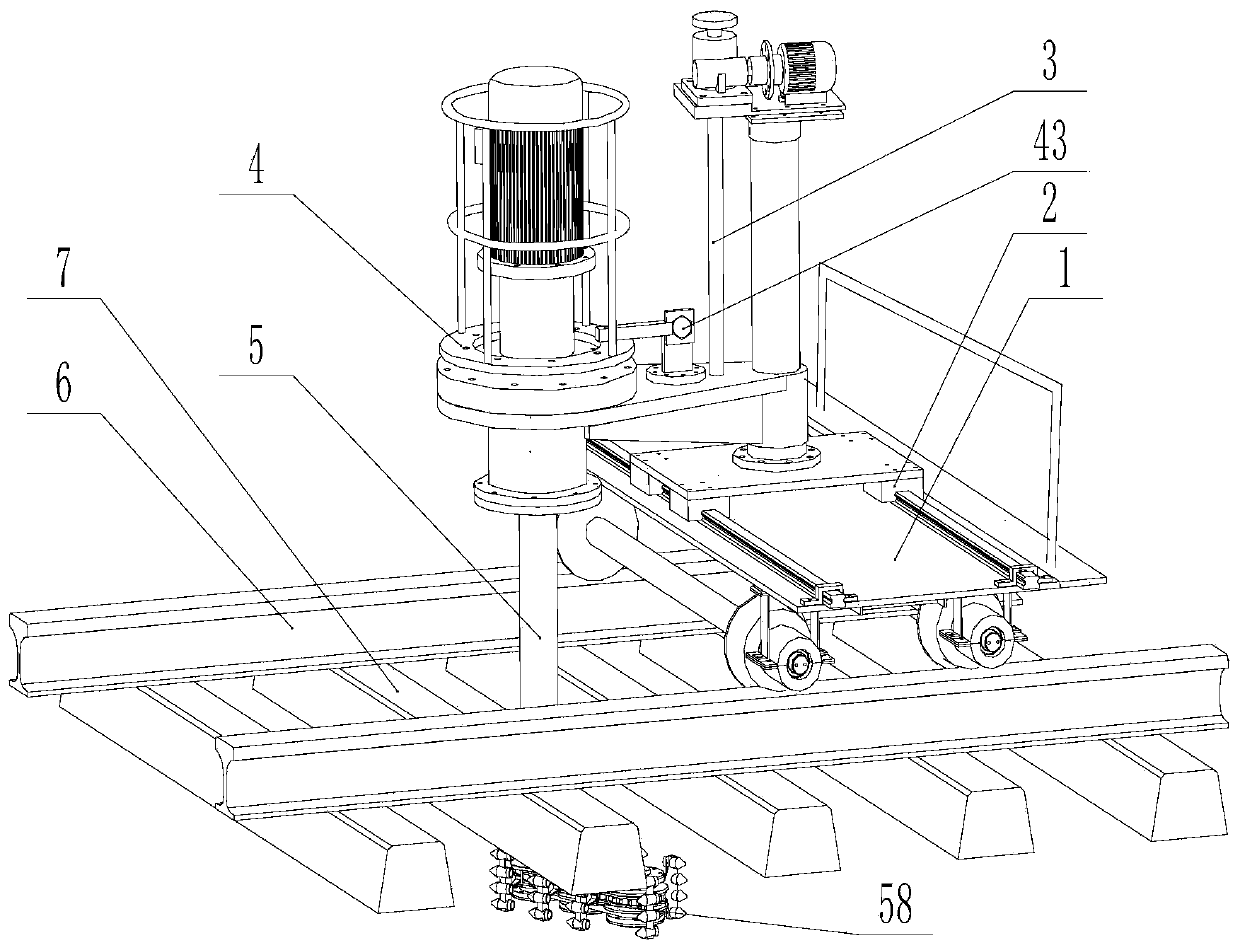

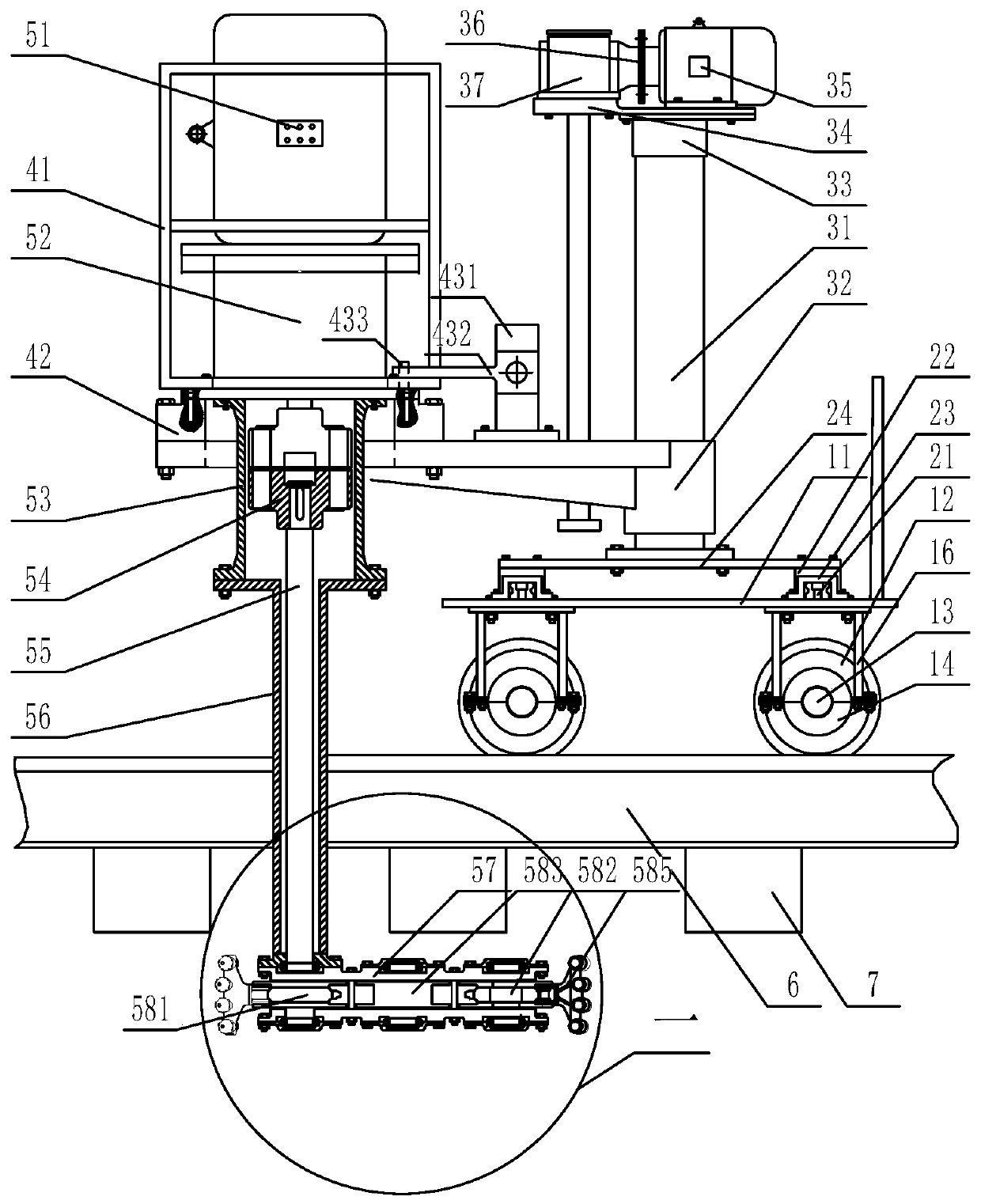

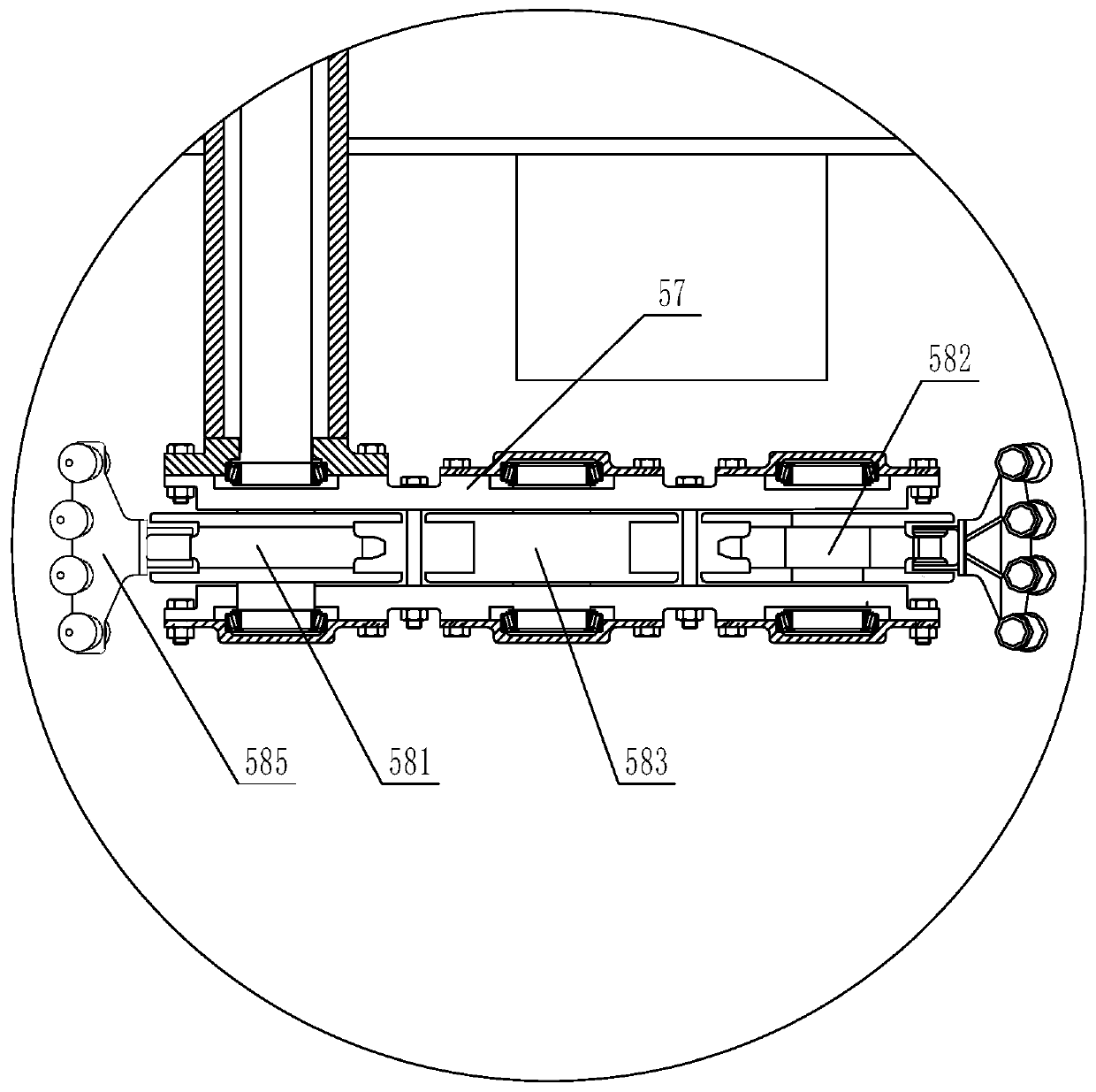

[0029] The small railway ballast cleaning equipment described in the present invention is very suitable for the "open skylight" mode in the cleaning of railway track beds in my country. First, the railway workers use shovels to clean up the ballast between the sleepers and under the sleepers on both sides of the rails. Since this part of the ballast bears little pressure from the railway, it is rarely compacted, and the space is not limited for easy cleaning. Then according to the distance to be cleaned up, several of the small-scale ballast cleaning equipment are placed on the rails to carry out the ballast cleaning operation.

[0030] The power source of the small ballast cleaning equipment of the present invention can be obtained in two ways, one way is to connect with the power distribution car in the railway screen cleaning operation process to obtain power, and the other way is to obtain power from each small ballast cleaning equipment frame 11 Install a small diesel gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com