Boiler pulse soot-blowing method and device thereof

A soot blowing device and pulse technology, which is applied in the field of boiler pulse soot blowing methods and devices, can solve the problems of complex equipment, high cost, wear and corrosion of pipes, etc., and achieve the effects of simple and reliable adjustment, high work efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

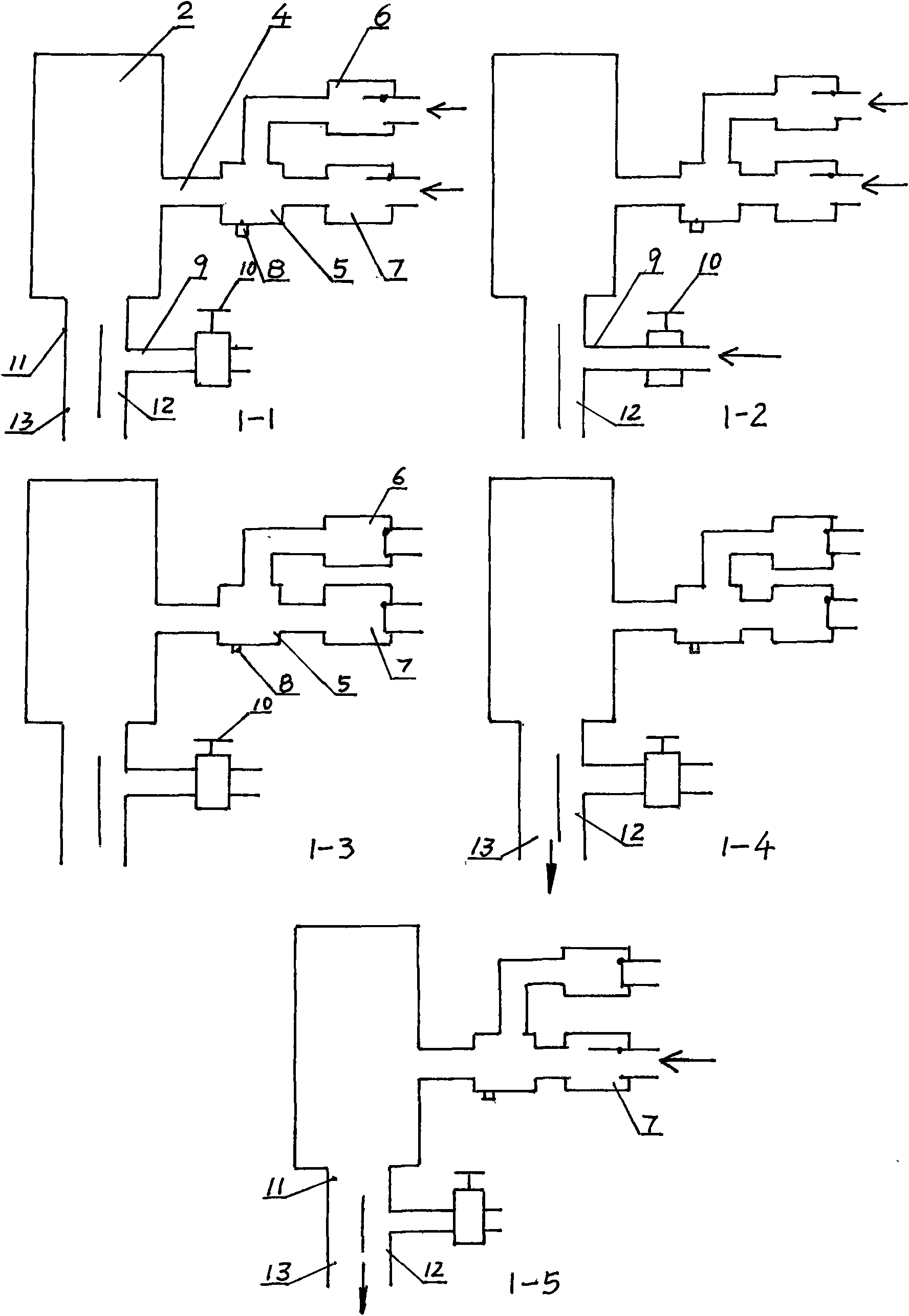

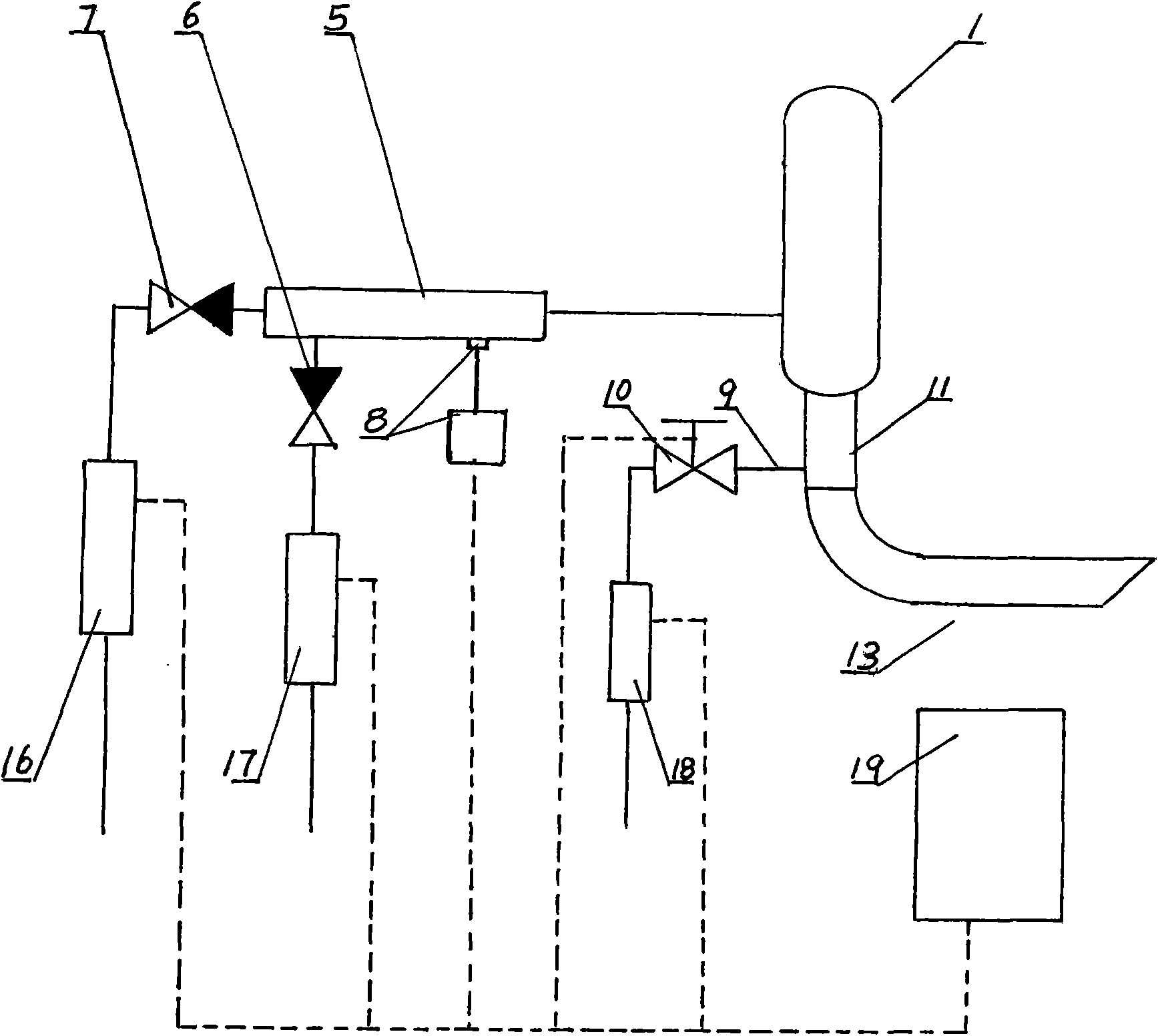

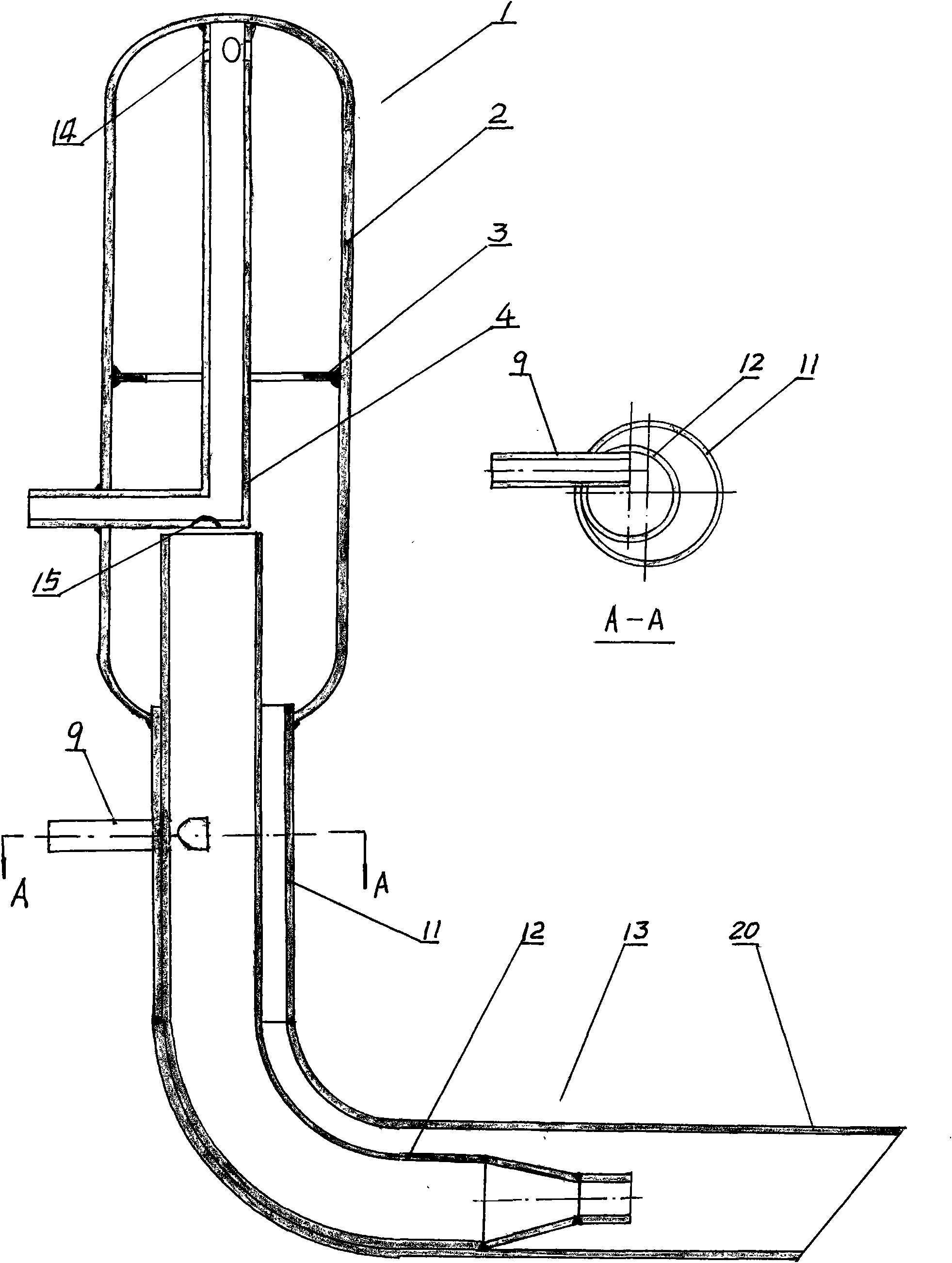

[0017] figure 1 A schematic diagram of a pulse soot blowing method for a boiler is shown. 1-1 in the figure represents the first step of the method of the present invention. Enter the tank body 2, the second step of the method of the present invention in 1-2 among the figures, the water inlet valve 10 is opened, fill water in the water jet pipe 12 in the nozzle through the water inlet pipe 9, the third step of the present invention in 1-3 among the figures , when the mixture of combustible gas and air fills the tank and the water is filled into the jet pipe, close the water inlet valve 10, the air valve 7 and the gas valve 6 are in the closed state, at this time the ignition coil and the high-energy electric nozzle 8 are energized, and the mixing The igniter 5 ignites the combustible mixture, and the flame gas causes a strong deflagration in the tank body 2 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com