Device and method for pre-removing coarse particle ash in front of SCR denitration device

A coarse particle and denitrification technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as ingress, and achieve the effect of reducing investment and high ash removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail below in conjunction with accompanying drawing:

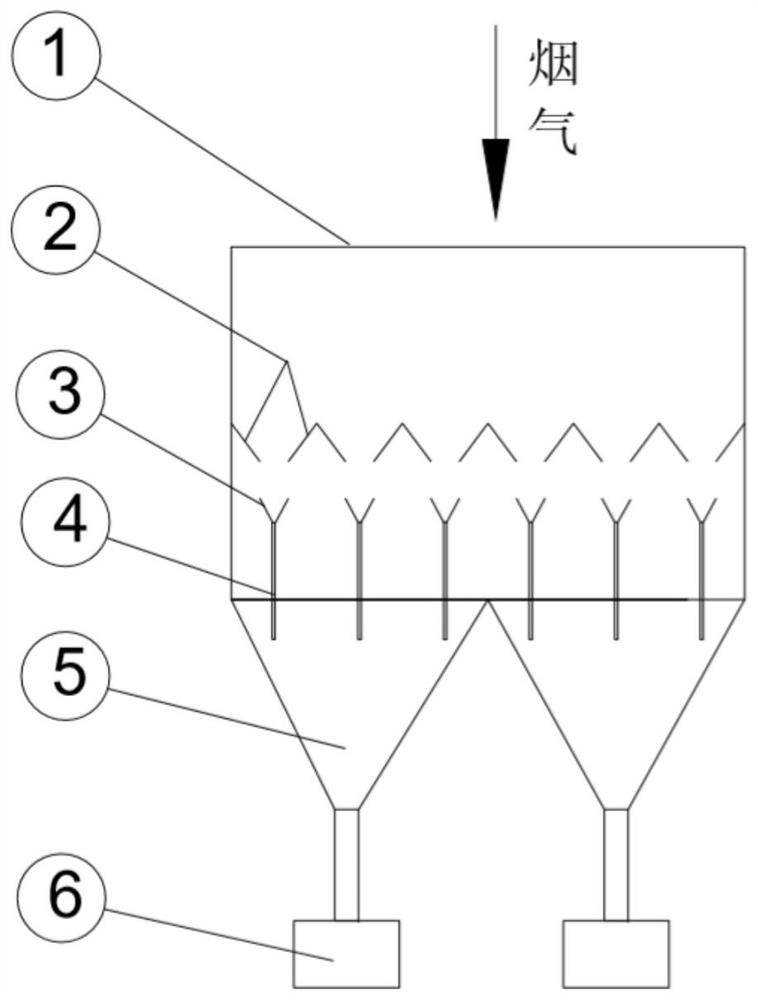

[0014] refer to figure 1 The device for pre-removing coarse particle ash before the SCR denitrification device according to the present invention includes an economizer outlet flue 1, an economizer ash hopper 5, several baffles 2, several ash collecting hoppers 3 and several ash falling pipes 4 ; The top of the economizer outlet flue 1 is provided with a flue gas inlet, each baffle 2 is distributed in the economizer outlet flue 1 in turn, and the outermost baffle 2 is fixed on the economizer outlet flue 1 On the outer wall, the outermost baffles 2 are obliquely distributed, and the rest of the baffles 2 have a herringbone structure or other structures that can enrich the dust and lead it into the ash hopper 3, while the smoke continues through the gaps between the baffles 2. In the structural form of the subsequent flue, there are gaps between adjacent baffles 2, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com