A PC mainframe dust removal box with good dust removal effect

A technology for a dust box and a host, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve the problems of influence, unsatisfactory dust removal effect, time-consuming and laborious dust removal, etc., to avoid pollution, convenient Effects of operations, improved efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

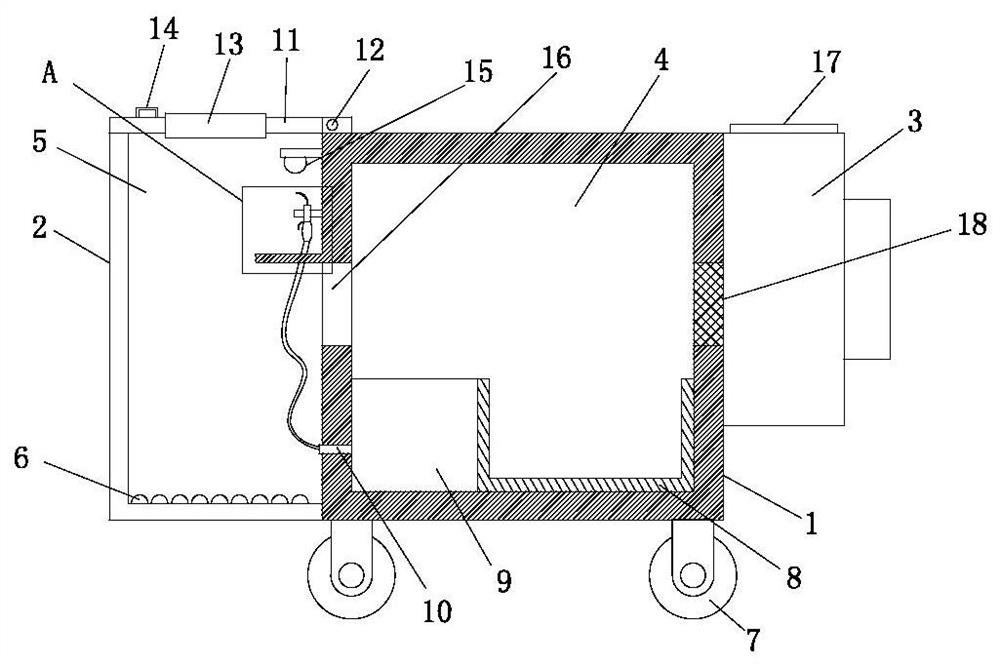

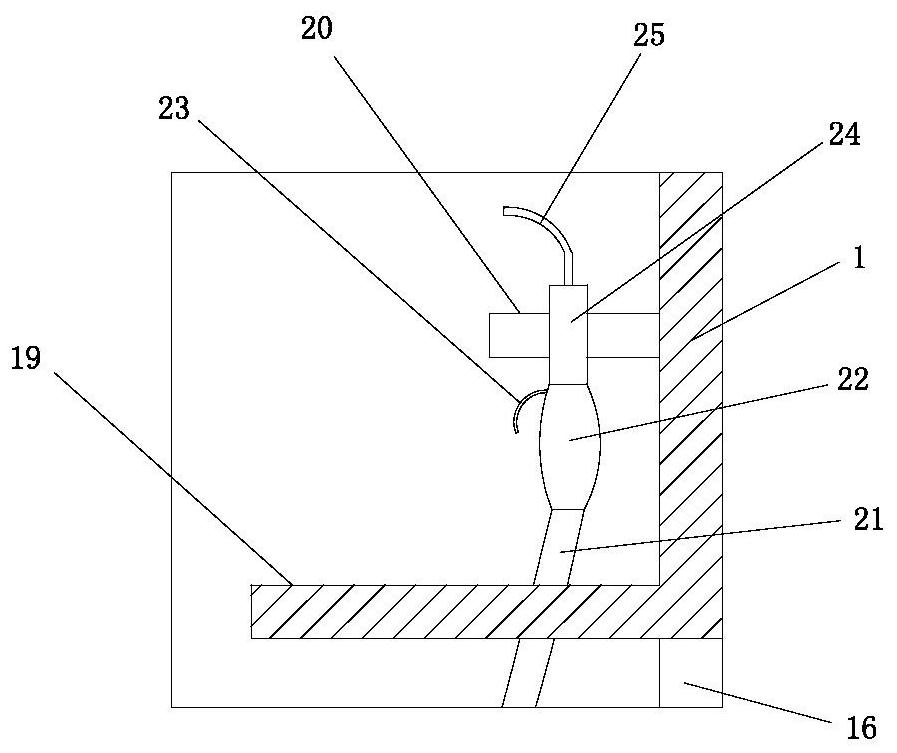

[0036] Such as Figure 1-2 As shown, the present invention provides a PC mainframe dust removal box with good dust removal effect, comprising a dust removal box 2, an ash fall bin 1 and a compression fan 3, the ash fall bin 1 is located between the dust removal box 2 and the compression fan 3, and the ash fall bin 1 is respectively communicated with the dust removal box 2 and the compressor fan 3, the compressor fan 3 is provided with an air outlet 17, the ash bin 1 is provided with a dust collection drawer 8 for collecting dust, and the ash bin 1 is also equipped with a blower 9, the blower 9 A first transmission pipe 10 is provided on the side close to the dust removal box 2, and an air supply hose 21 is installed on the first transmission pipe 10 in the dust removal chamber 5, and an air gun is installed on the side of the air supply hose 21 away from the transmission pipe 10 Handle 22, the side of air gun handle 22 away from air supply hose 21 is equipped with air gun hang...

Embodiment 2

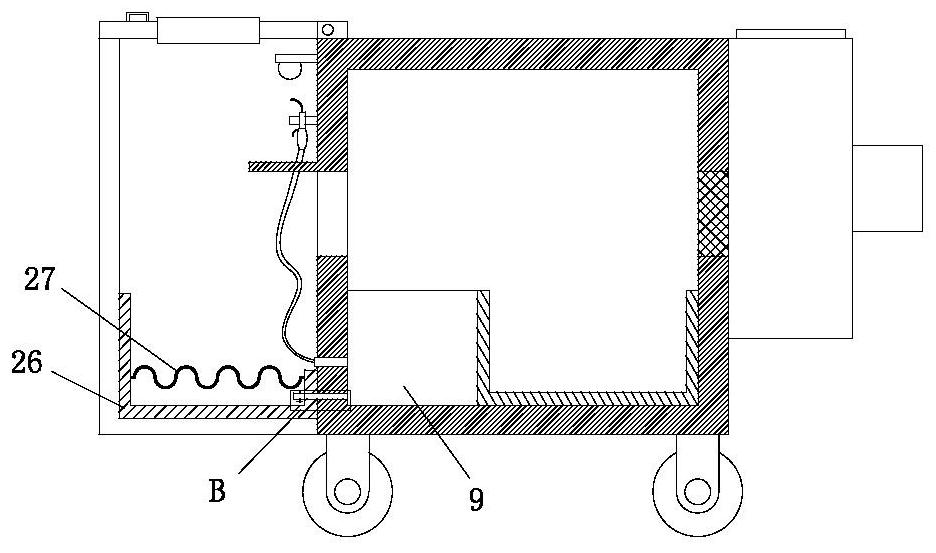

[0042] Such as Figure 3-4 The difference between the second embodiment and the first embodiment is that an equipment bearing frame 26 is installed on the inner bottom of the dust removal box 2, and a bearing platform 27 is installed in the equipment bearing frame 26, and the bearing platform 27 is a grid plate with a wave-shaped structure , the bearing platform 27 and the equipment bearing frame 26 form a cavity, and the side of the blower 9 close to the equipment bearing frame 26 is installed with a first air outlet pipe 28, the first air outlet pipe 28 runs through the ash bin 1 and the equipment bearing frame 26 and extends to the bearing In the cavity formed by the platform 27 and the equipment carrying frame 26 , a first air outlet valve 29 is provided on the first air outlet pipe 28 . By installing the equipment carrying frame 26 at the bottom of the dust removal box 2, the chassis to be dedusted is placed on a corrugated grid plate, and the chassis forms a gap with the...

Embodiment 3

[0044] Such as Figure 5-7 The difference between the third embodiment and the first embodiment is that an equipment carrying drawer 31 is placed on the inner bottom of the dust removal box 2, and a piston 32 is installed at the lower end of the equipment carrying drawer 31, and the piston 32 is installed on the side away from the equipment carrying drawer 26. Piston shaft 33 is arranged, and the side of piston shaft 33 away from equipment bearing drawer 26 is equipped with limiting plate 35, and the side of limiting plate 35 away from piston shaft 33 is equipped with roller mount 36, and roller 37 is installed on the roller mount 36. Place the chassis to be dedusted on the upper end of the equipment load drawer 31, and pull out and send the equipment load drawer 31 by the roller 37, which facilitates the placement and removal of the chassis, and in the process of dust removal, the piston 32 and the piston shaft 33 The cooperation of the roller 37 realizes the shock absorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com