Hay cutter with dust removal function

A chaff cutter and functional technology, applied in the field of hay cutters, can solve problems affecting the quality of forage, and achieve the effect of compact structure, simple operation and high ash removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

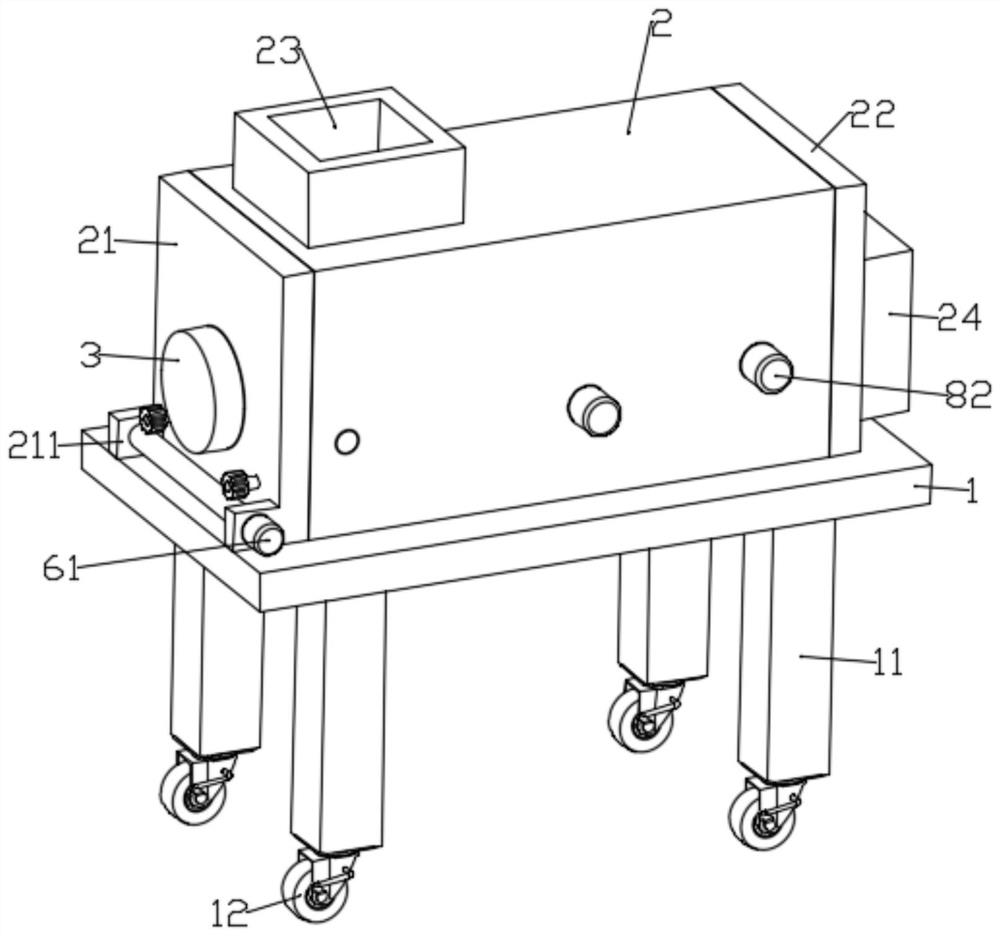

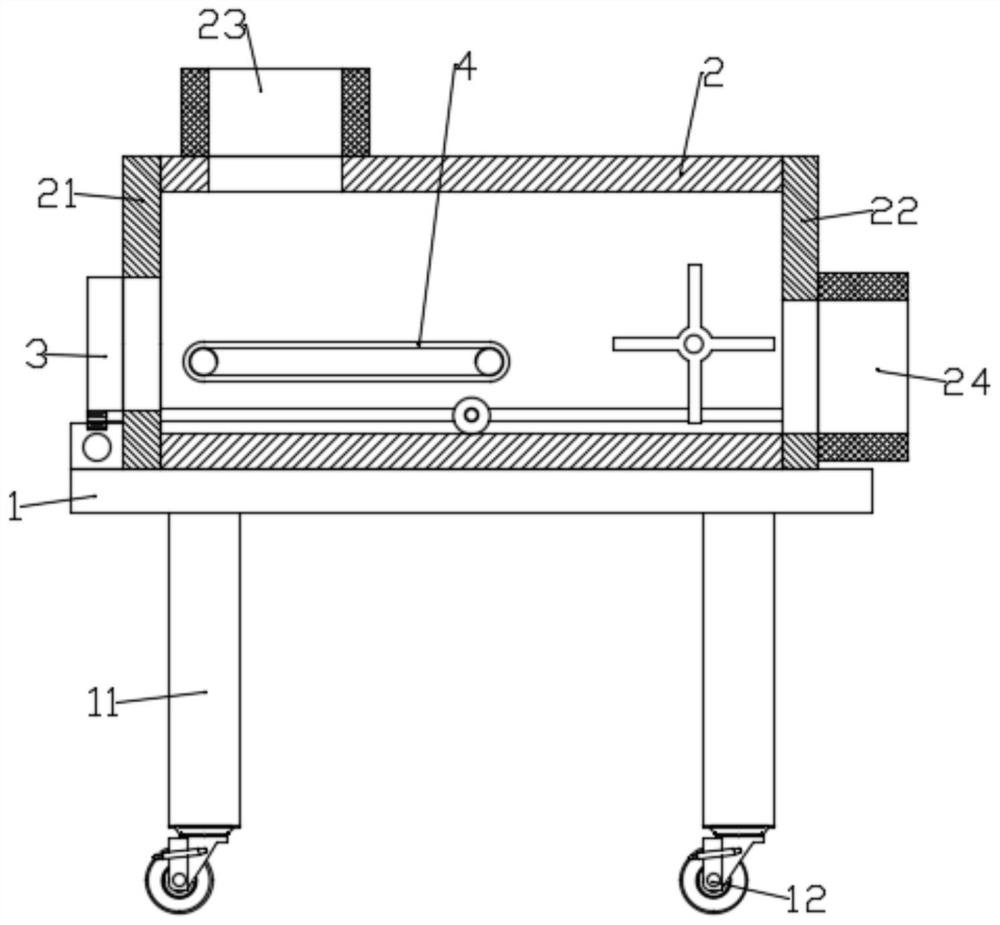

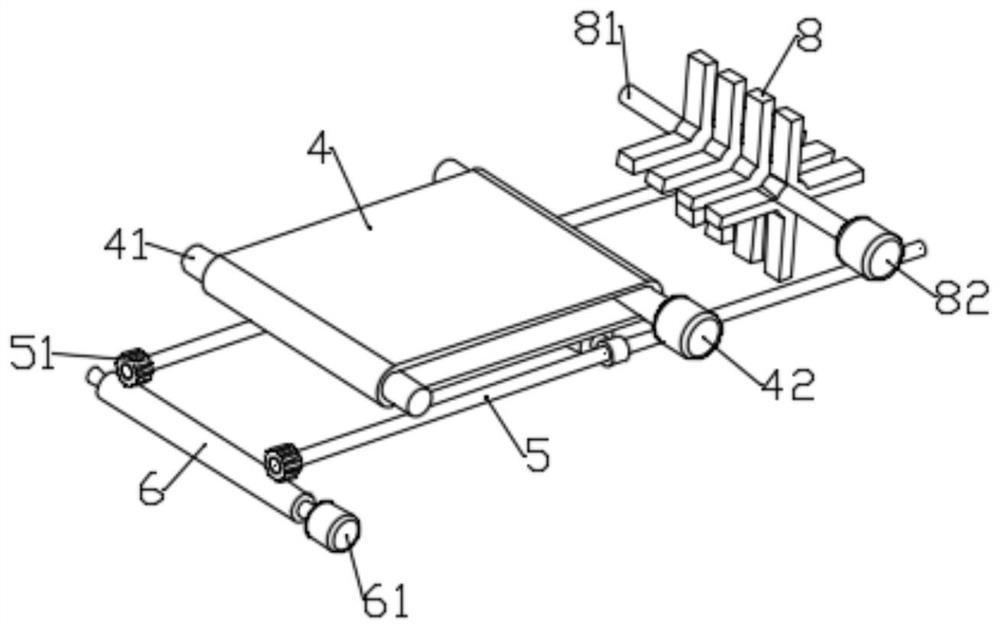

[0024] see Figure 1~4 , a hay cutter with ash removal function, comprising a support plate 1, a hay cutter casing 2 and a blower 3, a plurality of support legs 11 are fixedly installed on the lower end surface of the support board 1, and the hay cutter casing 2 Fixedly installed on the upper end surface of the support plate 1, the two ends of the mower box 2 are respectively fixedly installed with a first baffle 21 and a second baffle 22, and the second baffle 22 is far away from the bottom of the mower box 2. A discharge cylinder 24 is installed through one side, and a feed cylinder 23 is installed through the upper side of the chaff cutter box 2 close to the end of the first baffle plate 21, and a blower 3 is fixedly installed in the first baffle plate 21, so The bottom between the first baffle plate 21 and the second baffle plate 22 is provided with a brush-moving dust-cleaning mechanism, and the inside of the chaff cutter box 2 is provided with a transmission belt 4, and ...

Embodiment 2

[0030] see Figure 1~4 , a hay cutter with ash removal function. On the basis of Embodiment 1, a pair of rotating shafts 41 are installed in the casing 2 of the hay chaff, and one end of the rotating shaft 41 is connected to the output of the first motor 42. The ends are fixedly connected, the transmission belt 4 is installed on the outer surface of a pair of rotating shafts 41, and the bottom of the support leg 11 is fixedly equipped with a universal wheel 12 with a pedal brake function, which is convenient for a dust removal function. To move and fix the position of the mower, the end of the discharge cylinder 24 away from the casing 2 of the mower is inclined downward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com