Dust removal device used for rice fine processing and usage method

A kind of dust removal equipment and rice technology, applied in the direction of dust removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of harmful production personnel's health, affecting the environment of processing sites, flying dust in processing sites, etc., and achieve the effect of iron removal Obvious, weaken the electrostatic adsorption effect, improve the effect of ash removal efficiency

Active Publication Date: 2019-04-30

江西省李梦粮油有限公司

View PDF9 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] During the husking process, some fine dust will be produced by crushing chaff, but the static electricity generated by friction will make most of the dust adhere to the surface of brown rice, and carry dust in every subsequent process, which is not conducive to the production process. Finishing of rice

After the rice is processed to form rice, there are many fine husks and rice dust inside the rice, and the rice formed after the rice is rolled is complete or fragmentary, and it is difficult to distinguish after mixing together. The rice that has been mechanically processed The heat is relatively large, and the heat is not easy to dissipate after the rice is piled up. The existing machinery needs to use multiple mechanical devices to process the freshly rolled rice, such as screening, dust removal, and cooling, and it can only be completed after multiple steps. Not only time-consuming, but also labor-intensive

[0004] At present, there is no dedusting method for the dust on the surface, which leads to the situation of flying dust in the processing site, which seriously affects the environment of the processing site, and will be harmful to the health of production personnel if it continues for a long time.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0039] Take 100 catties of husked brown rice and put it into the equipment for dust removal.

Embodiment 2

[0041] Take 150 catties of husked brown rice and put it into the equipment for dust removal.

Embodiment 3

[0043] Take 100 catties of rice after rolling and put it into the equipment for dust removal operation.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

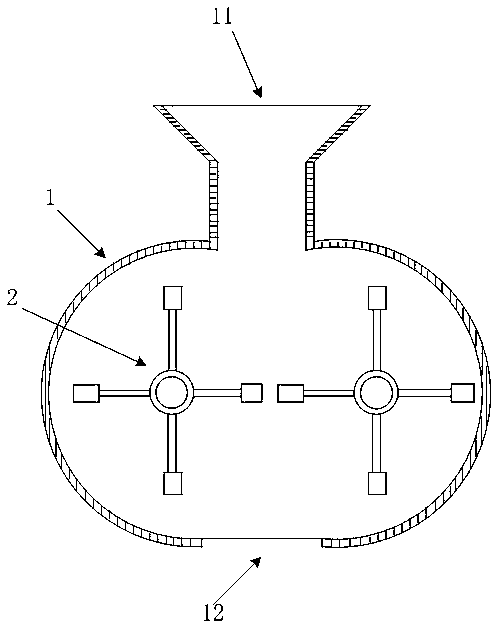

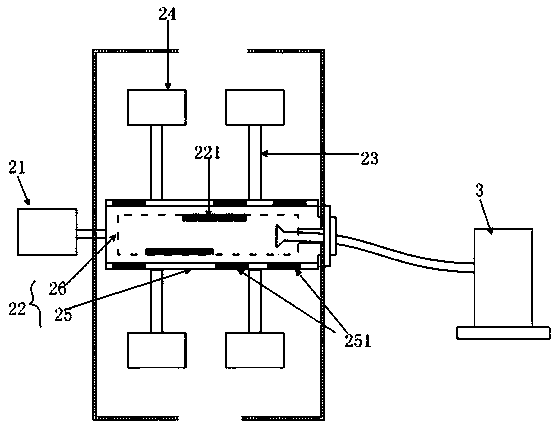

The invention discloses a dust removal device used for rice fine processing and a usage method. The device includes a shell body, a stirring device located in the shell body, and a dust suction deviceoutside the shell body. Compared with the prior art, the device utilizes openings on a stirring shaft to cooperate with the dust suction device to process materials, the separation efficiency is high, and process steps are reduced, thereby improving the ash removing efficiency; compared with a conventional process, the process no longer adopts a centrifugal principle, does not increase generationof broken rice, and cooperates with dry ice to cool the interior of the materials, the electrostatic adsorption effect is decreased, after the temperature is lowered, dust on the materials is polished down more easily, and the dust removal efficiency is improved; magnets are disposed inside an inner shell and can fully attract iron scraps, and the like in the materials, and so, production and food safety is ensured, and dust removal is more thorough; and the device is suitable for all links of unhusked rice production, has a wide range of applications, and can effectively remove the iron scraps in the materials, the iron scraps are collected in the inner shell, if the iron scraps contained in the magnets are too much, the iron scraps cannot fall into the device, and the iron removal effect is more obvious.

Description

technical field [0001] The invention relates to the technical field of rice processing, in particular to a dust removal device for rice finishing and a use method. Background technique [0002] Rice is the finished product of paddy after cleaning, husking, rice milling, finishing and other processes. The cleaning process is to use appropriate equipment, through appropriate technological processes and proper operation methods, to remove all kinds of impurities mixed in the rice, so as to improve the quality of the finished rice, and to use magnets to remove iron nails and iron filings in the rice. To ensure production safety. The hulling process is to use a rubber roller huller or an emery huller to remove the chaff of the rice and separate the chaff from the brown rice. The rice milling process is to use a rice mill to grind and rub the brown rice to separate the cortex and endosperm, and then to brush the rice, remove the bran, crush the rice, and dry the rice, so that th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B02B3/00B02B7/00B02B7/02B08B15/04B03C1/26B03C1/30B07B1/04

CPCB02B3/00B02B7/00B02B7/02B03C1/26B03C1/30B07B1/04B08B15/04

Inventor 刘志东

Owner 江西省李梦粮油有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com