Synthetic gas washing system and washing method

A washing method and synthesis gas technology, applied in the field of washing, can solve the problems of poor washing ash removal effect and ash in the washing tower, and achieve the effect of high ash removal efficiency and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

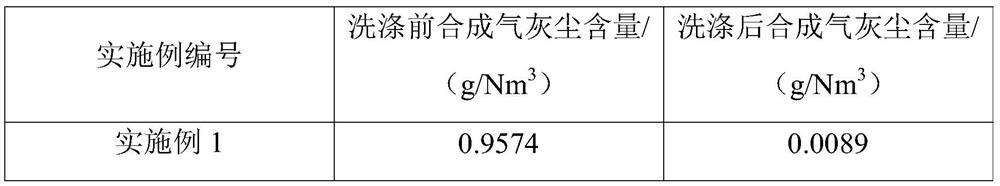

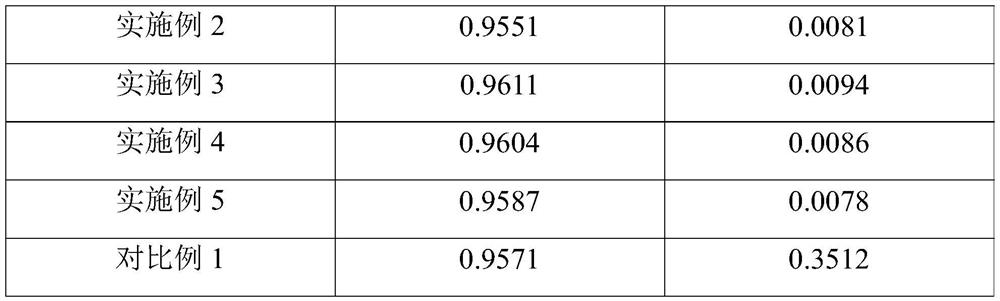

Embodiment 1-5

[0065] Embodiment 1-5 syngas scrubbing method is all implemented in the syngas scrubbing system described below:

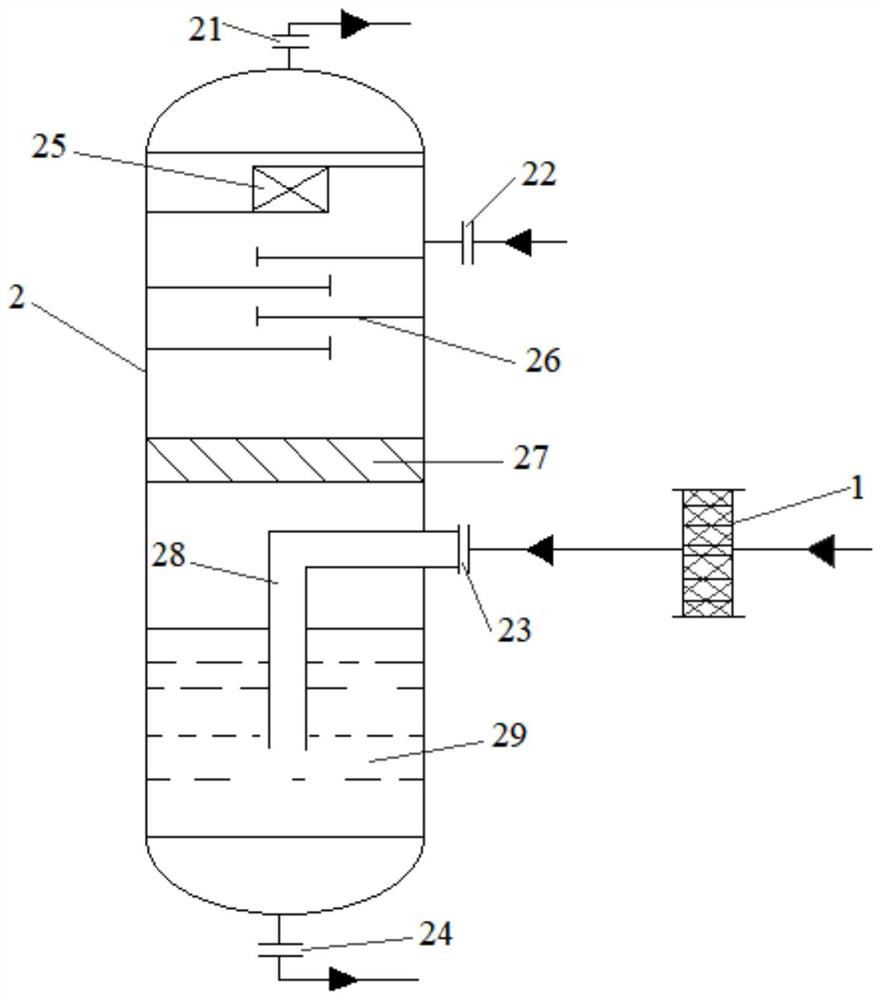

[0066] The syngas scrubbing system such as figure 1 As shown, the washing system includes a filter 1 and a washing tower 2, the air outlet of the filter 1 is connected to the air inlet 23 of the washing tower 2; the washing tower 2 is sequentially provided with air outlets from top to bottom 21, demister 25, water inlet 22, tray 26, packing layer 27, air inlet 23, water area pool 29 and water outlet 24; Described washing tower 2 also comprises inlet pipe 28, and one end of described inlet pipe 28 Connected with the air inlet 23, the other end of the air inlet pipe 28 extends into the water pool 29; the demister 25, the tray 26, the packing layer 27, and the water pool 29 are arranged in the washing tower 2 inside; the water outlet 24 is arranged at the bottom of the water pool 29; the number of the trays 26 is 4; the distance between the trays 26 is 85cm; the pac...

Embodiment 1

[0068] The synthesis gas (the pressure of the synthesis gas is 6MPa, the temperature of the synthesis gas is 243°C) is sent to the filter 1 for filtration, and then sent to the inlet 23 of the scrubber 2, and enters the water area through the inlet pipe 28 of the scrubber 2 Wash and remove dust in the pool 29, then pass through the packing layer 27 and the tray 26 successively, contact with the pure water from the water inlet 22 in reverse, wash and remove the dust, then enter the demister 25 for defoaming, and finally remove the demister from the demister 25 The upper air outlet 21 is discharged;

[0069] Wherein, the pure water enters from the water inlet 24, flows through each tray 26 below in turn, then flows through the packing layer 27, and then falls into the water area pool 29 with gravity to maintain the liquid level of the water area pool 29, and the excess pure water flows from The water outlet 24 at the bottom of the water area pool 29 is discharged;

[0070] The ...

Embodiment 2

[0072] The synthesis gas (the pressure of the synthesis gas is 6.3MPa, and the temperature of the synthesis gas is 230°C) is sent to the filter 1 for filtration, and then sent to the inlet 23 of the scrubber 2, and enters through the inlet pipe 28 of the scrubber 2 Wash and remove dust in the water area pool 29, then pass through the packing layer 27 and the tray 26 successively, contact with the pure water from the water inlet 22 in reverse, carry out washing and dust removal, then enter the demister 25 for defoaming, and finally remove the demister from the demister The air outlet 21 above the 25 is discharged;

[0073] Wherein, the pure water enters from the water inlet 24, flows through each tray 26 below in turn, then flows through the packing layer 27, and then falls into the water area pool 29 with gravity to maintain the liquid level of the water area pool 29, and the excess pure water flows from The water outlet 24 at the bottom of the water area pool 29 is discharged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com