Intelligent liquid cloud feeding system for large livestock farm

A kind of farm, intelligent technology, applied in animal feeding devices, poultry industry, applications, etc., can solve the problem of feeding time, feeding amount can not be accurately controlled, feeding easily left on the machine, low feeding efficiency, etc. problems, to reduce wiring and failure rates, avoid mildew and morbidity, and reduce vehicle transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] Below in conjunction with embodiment the present invention is further described in detail.

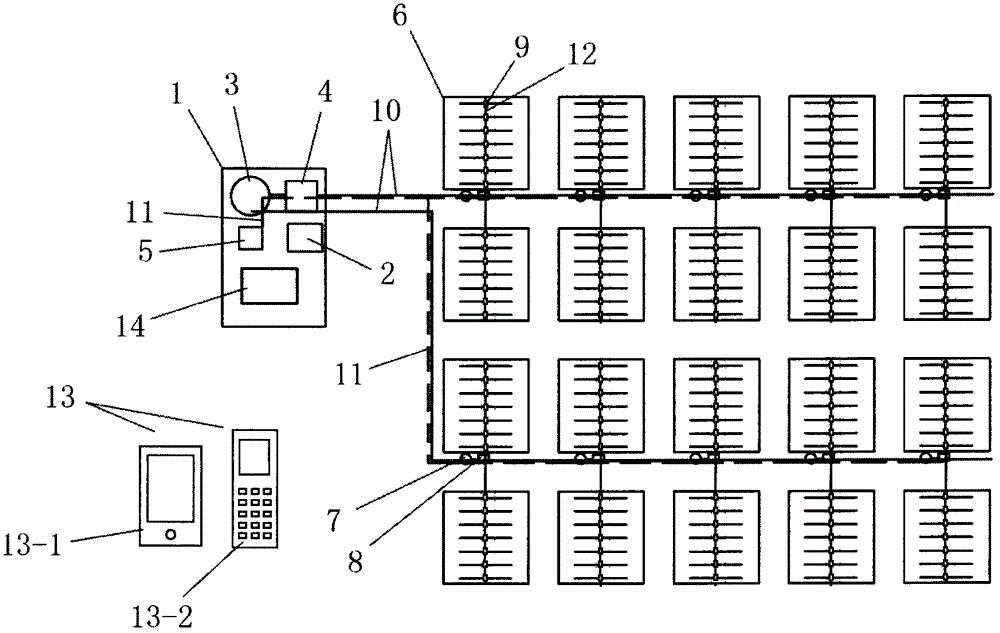

[0020] Such as figure 1 As shown, an intelligent liquid cloud feeding system for a large-scale farm includes a batching bin 1 and a pig house 6. The batching bin 1 is equipped with an intelligent central control room 2, a fully intelligent proportioning constant temperature mixing tank 3, a fully intelligent The power host 4 and the screw air compressor 5; the distribution pipeline 12 is installed in the pigsty 6, and the intelligent feeding terminal 9 is arranged on the distribution pipeline 12; the distribution mixing tank is arranged outside the pigsty 6 7 and a material distribution conveyor 8; the screw air compressor 5 is connected to the material distribution mixing tank 7 through a compressed air pipeline 11; the fully intelligent proportioning constant temperature mixing tank 3 is connected to a fully intelligent power host 4, and is conveyed through the main material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com