Full-automatic rotor measuring machine

A rotor measuring machine, fully automatic technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of misreading of measured values, manual misplacement of workpieces, etc., and achieve the effect of compact structure, high precision and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

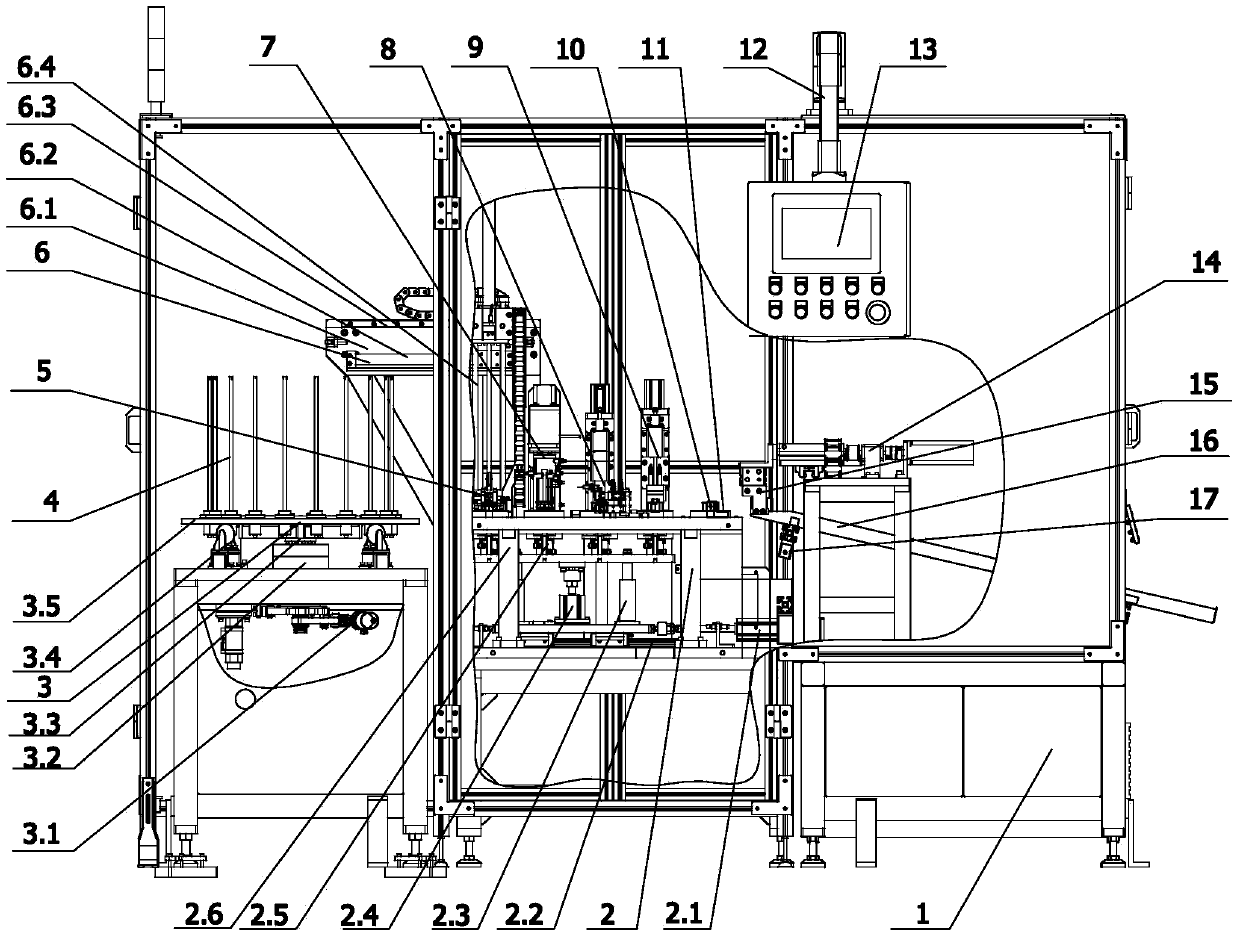

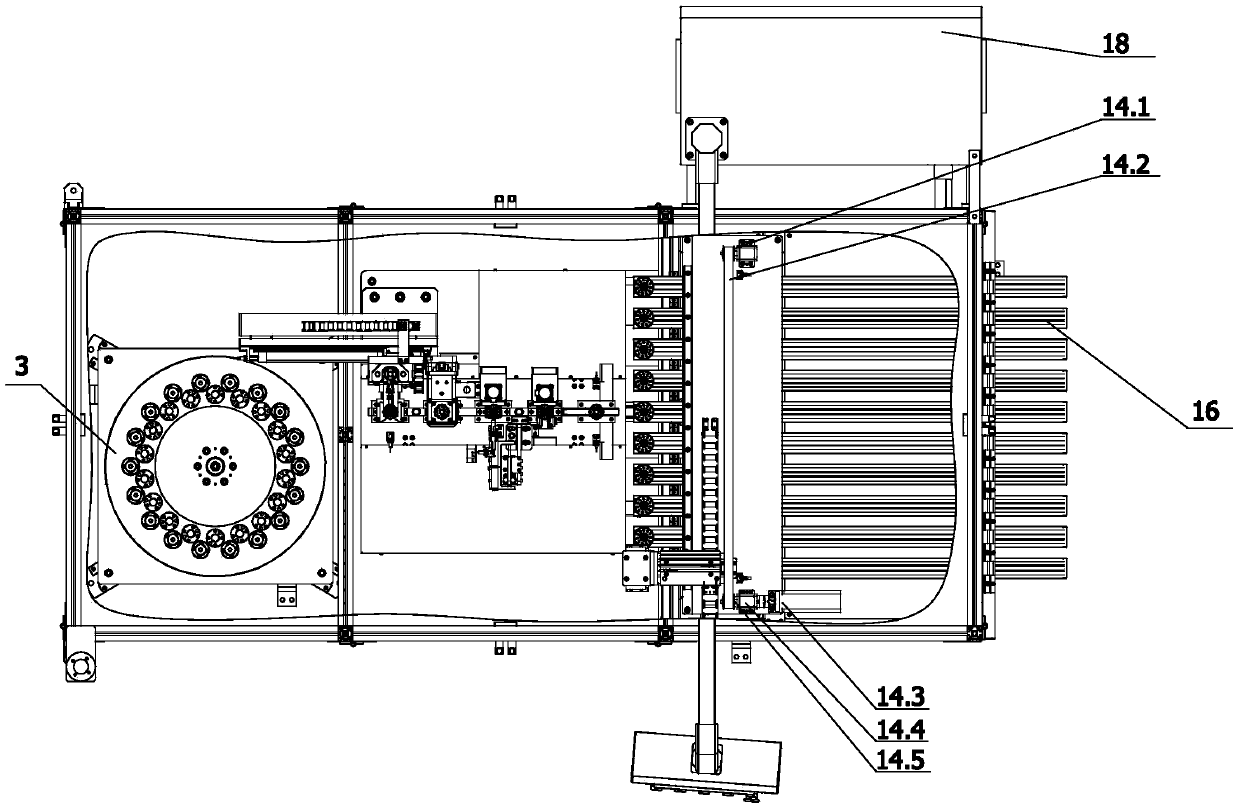

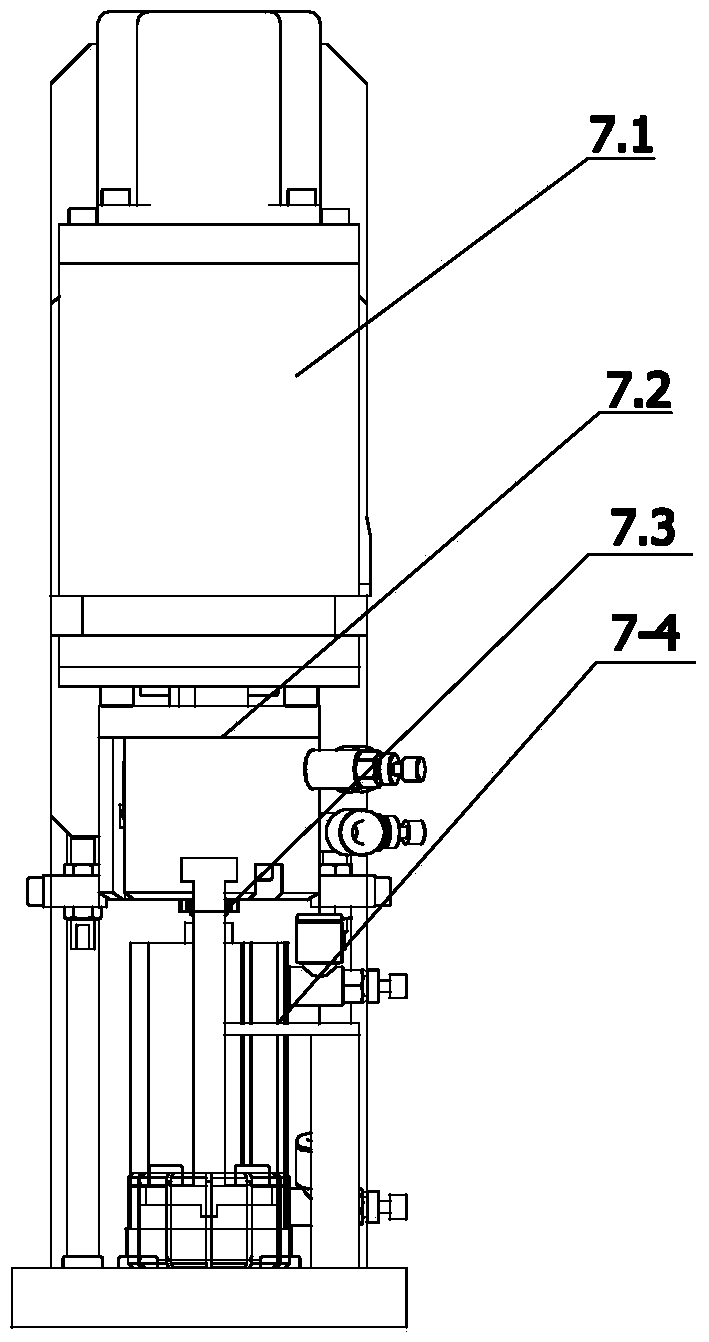

[0024] Such as Figure 1~2 As shown, the present invention mainly includes a frame 1, a feeding step mechanism 2, a stepping rotary feeding tray 3, a feeding rod 4, a feeding manipulator 5, a material shifting mechanism 6, a rotary positioning mechanism 7, and a groove width Measuring mechanism 8, thickness measuring mechanism 9, optical fiber sensor 10, unloading station 11, alarm light 12, operation box 13, servo motor moving grouping mechanism 14, unloading manipulator 15, gravity material channel 16, full material alarm switch 17 and Electric control cabinet 18.

[0025] The left part of the frame 1 is provided with a step-by-step rotary feed tray 3 for feeding, and a plurality of feeding rods 4 are connected to the step-by-step rotary feed tray 3, and a plurality of feed rods 4 are placed on the step-by-step rotary feed tray for feeding. 3 evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com