Water-based inorganic synthetic fluid coat, preparation method thereof and use method thereof

A liquid paint and inorganic synthesis technology, which is applied in the field of paint products in building wall decoration materials, can solve the problems of not being able to reduce construction fees and costs, traditional single construction operations, and inconvenient coloring treatment, etc., and achieve reduction Flame spread value, good breathing and UV absorption, excellent anti-mold and sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

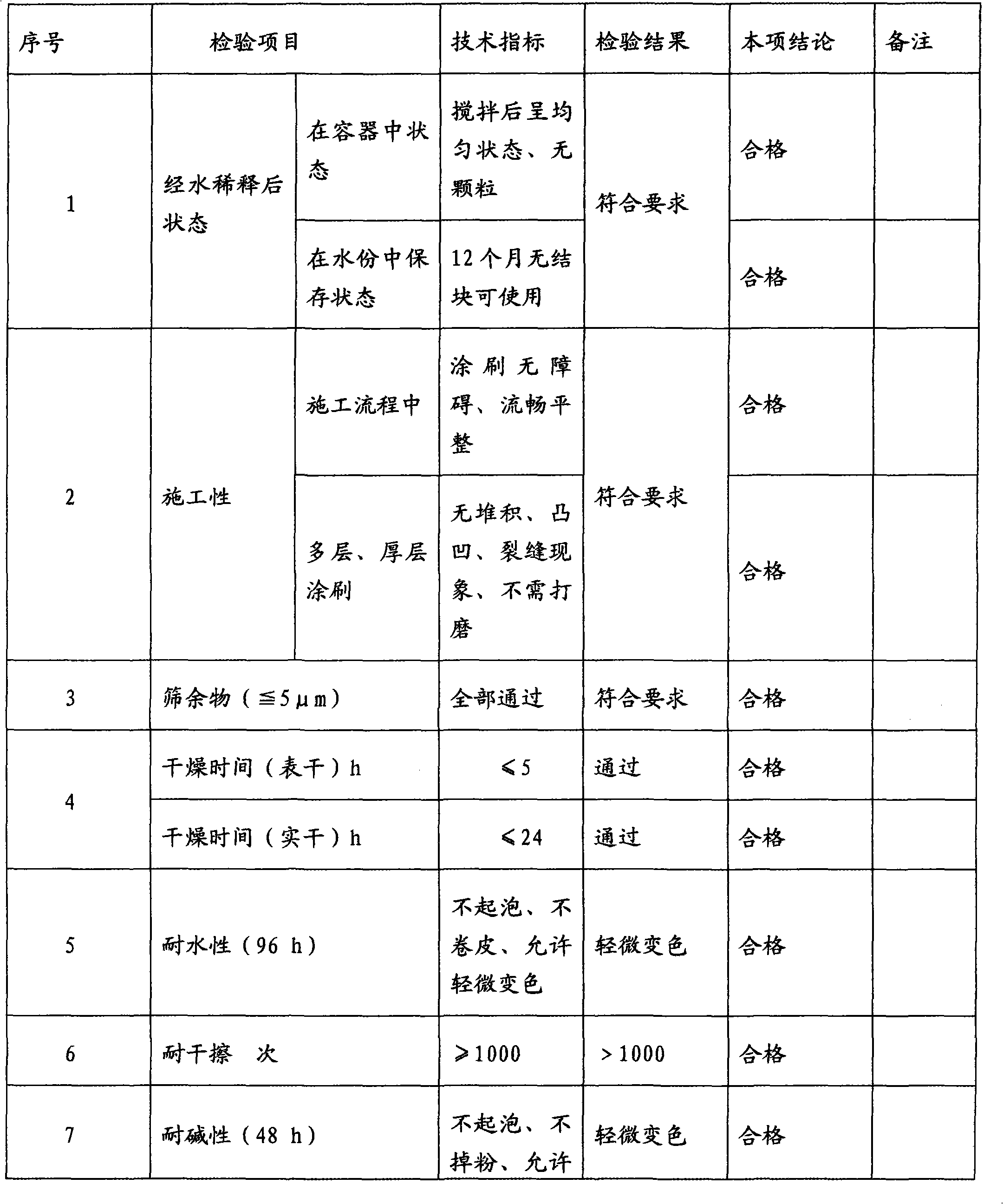

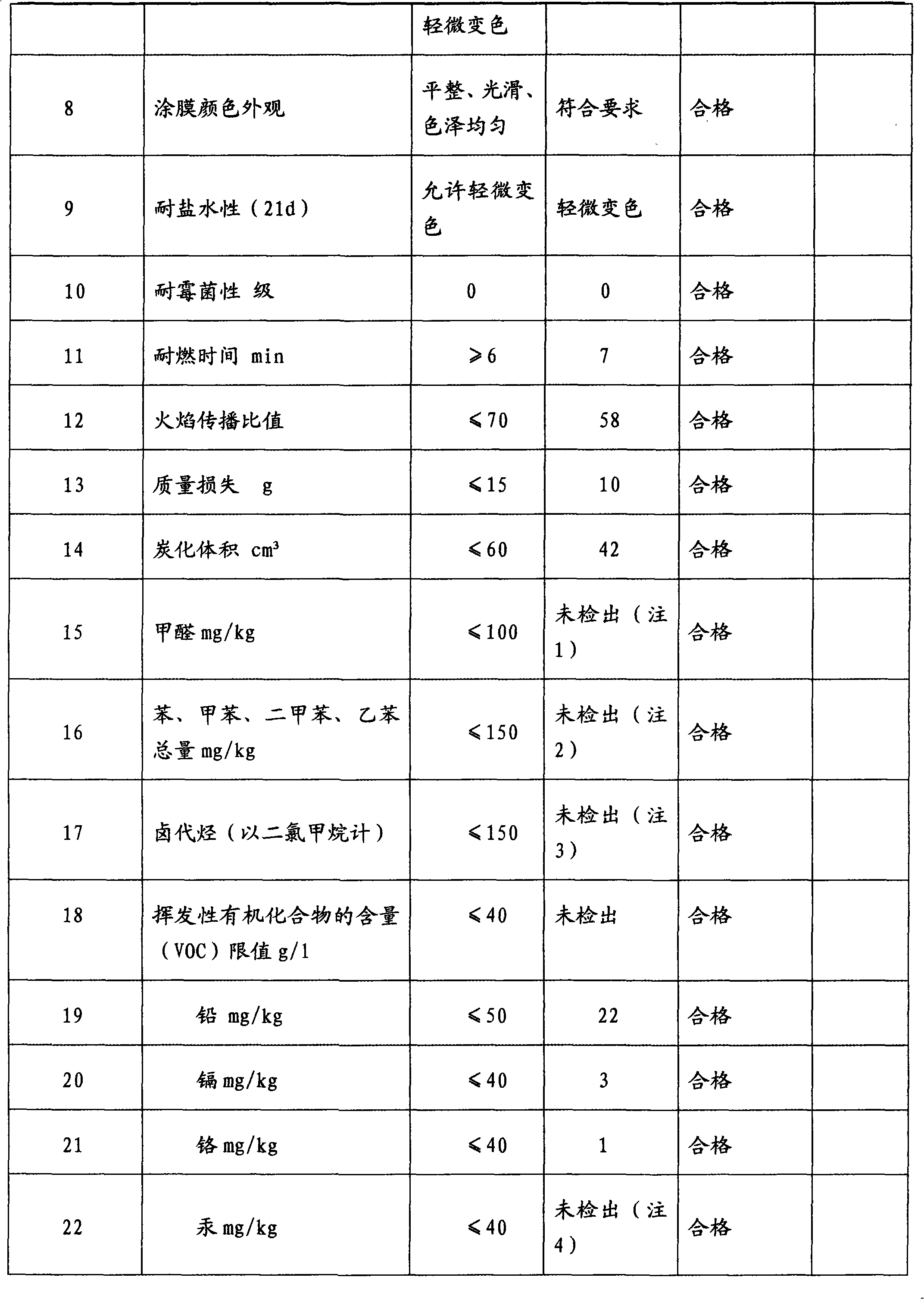

Examples

Embodiment 1

[0030] 25 parts of calcite, 13 parts of wollastonite, 5 parts of light calcium carbonate, 10 parts of ash calcium powder

[0031] Shuangfei powder 37 parts mica powder 10 parts pure water 60-80 parts methyl cellulose 0.005 parts ethyl cellulose 0.002 parts hydroxypropyl cellulose 0.001 parts water-based nanomaterials 0.002 parts polypropionyl ammonium 0.001 parts water-based defoamer and water-based silicon oxide.

Embodiment 2

[0033] 21.5 parts of calcite, 20 parts of wollastonite, 8 parts of light calcium carbonate, 10 parts of ash calcium powder

[0034] 25 parts of double fly powder, 10.5 parts of mica powder, 5 parts of anatase titanium dioxide, 65-80 parts of pure water

[0035] 0.006 part of methyl cellulose 0.002 part of ethyl cellulose 0.002 part of water-based nanomaterial 0.002 part of hydroxypropyl cellulose 0.002 part of polypropionyl ammonium Proper amount of water-based defoamer and water-based silicon oxide.

Embodiment 3

[0037] 20.5 parts of calcite, 15 parts of wollastonite, 8 parts of light calcium carbonate, 10 parts of ash calcium powder

[0038] 20 parts of gypsum powder, 21.5 parts of Shuangfei powder, 5 parts of zinc white powder, 85-90 parts of pure water

[0039] 0.006 part of methyl cellulose, 0.002 part of ethyl cellulose, 0.003 part of water-based nanomaterial, 0.002 part of polypropionyl ammonium, 0.003 part of hydroxypropyl cellulose, appropriate amount of water-based defoamer and water-based silicon oxide.

[0040] The present invention is further set forth below according to above-mentioned example.

[0041]In the present invention, although calcite, light calcium carbonate, gray calcium powder, double fly powder, anatase white powder, wollastonite, and mica powder are still used as the main calcium-containing aggregates of the water-based inorganic synthetic liquid coating, but simultaneously Water methyl cellulose, ethyl cellulose, hydroxypropyl methyl cellulose, polypropion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com