Heat-preserving material for outer wall

An external wall thermal insulation and raw material technology, which is applied in the field of external wall thermal insulation materials, can solve the problems that thermal insulation materials do not have sound insulation and radiation, low working efficiency of installers, and performance degradation of thermal insulation materials, etc., so as to eliminate fire hazards and overcome poor fire performance. , the effect of reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

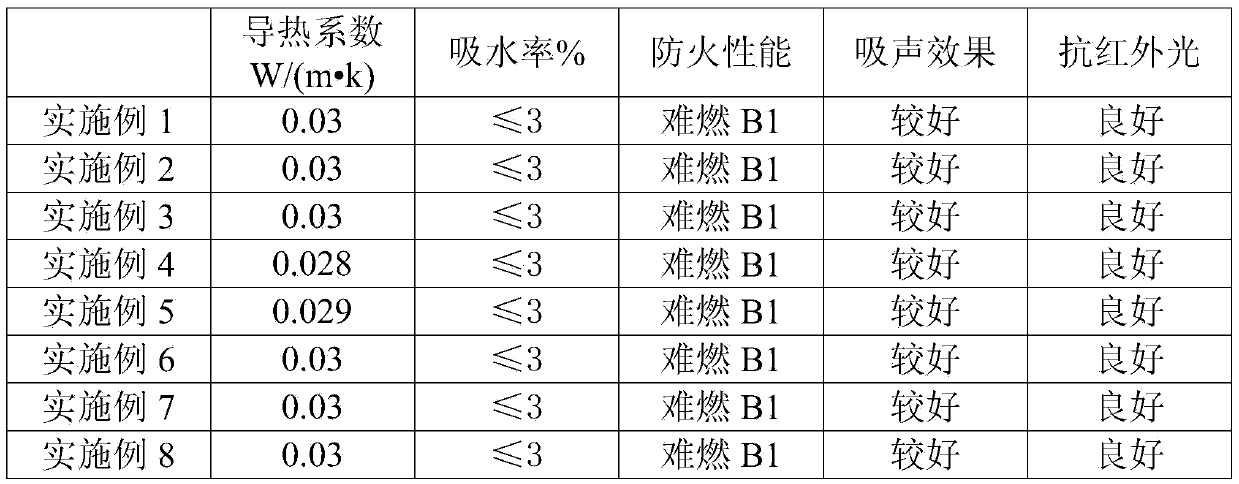

Examples

Embodiment 1

[0033] An external wall insulation material, comprising the following raw materials in parts by weight: 45 parts of fly ash Portland cement, 15 parts of white bleach beads, nano TiO 2 1.5 parts, 0.5 parts of ceramic cotton fiber, 5 parts of aluminum silicate fiber cotton, 0.2 parts of polysiloxane powder, 3 parts of elastic emulsion, 6 parts of expanded vitrified microbead thermal insulation slurry, 3.5 parts of polypropylene fiber, inorganic nano-coating 2 parts, 0.05 parts of foam silk, 0.05 parts of bamboo fiber and 10 parts of flame retardant, wherein the thermal insulation slurry of expanded vitrified microbeads is composed of expanded vitrified microbeads and thermal insulation glue powder of expanded vitrified microbeads, and the expanded vitrified microspheres Beads: expanded vitrified microbead insulation rubber powder = 1:0.5; the flame retardant is a mixture of aluminum hydroxide and magnesium hydroxide, aluminum hydroxide: magnesium hydroxide = 1:1.

[0034] The pr...

Embodiment 2

[0036] An external wall insulation material, comprising the following raw materials in parts by weight: 55 parts of fly ash portland cement, 20 parts of white bleach beads, nano TiO2 2 parts, 1.2 parts of ceramic cotton fiber, 10 parts of aluminum silicate fiber cotton, 0.6 parts of sodium methyl siliconate, 7 parts of elastic emulsion, 9 parts of expanded vitrified microbead thermal insulation slurry, 4.5 parts of polypropylene fiber, inorganic nano-coating 5 parts, 0.1 part of foam silk, 0.1 part of bamboo fiber and 15 parts of flame retardant; wherein the thermal insulation slurry of expanded vitrified microbeads is composed of expanded vitrified microbeads and expanded vitrified microbead thermal insulation glue powder, and expanded vitrified microbeads Beads: expanded vitrified microbead insulation rubber powder = 1:1; flame retardant is a mixture of aluminum hydroxide and magnesium hydroxide, aluminum hydroxide: magnesium hydroxide = 1:2.

[0037] The preparation process ...

Embodiment 3

[0039] An external wall insulation material, comprising the following raw materials in parts by weight: 55 parts of fly ash Portland cement, 16 parts of white bleach beads, nano TiO 2 2 parts, 0.8 parts of ceramic cotton fiber, 6 parts of aluminum silicate fiber cotton, 0.3 parts of polysiloxane powder, 3 parts of elastic emulsion, 8 parts of expanded vitrified microbead thermal insulation slurry, 3.7 parts of polypropylene fiber, inorganic nano-coating 3 parts, 0.07 parts of foam silk, 0.07 parts of bamboo fiber and 12 parts of flame retardant; wherein the thermal insulation slurry of expanded vitrified microbeads is composed of expanded vitrified microbeads and expanded vitrified microbead thermal insulation glue powder, and expanded vitrified microbeads Beads: expanded vitrified microbead insulation rubber powder = 1:2; flame retardant is a mixture of aluminum hydroxide and magnesium hydroxide, aluminum hydroxide: magnesium hydroxide = 1:1.5.

[0040] The preparation proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com