Process and system for treating electric power plant waste water

A power plant wastewater and treatment method technology, applied in the system field for realizing the process method, can solve the problems of unfavorable desulfurization wastewater reuse, failure to remove desulfurization wastewater, adverse environmental impact, etc., and achieve strong impact resistance, operational reliability and stability Strong performance and wide range of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

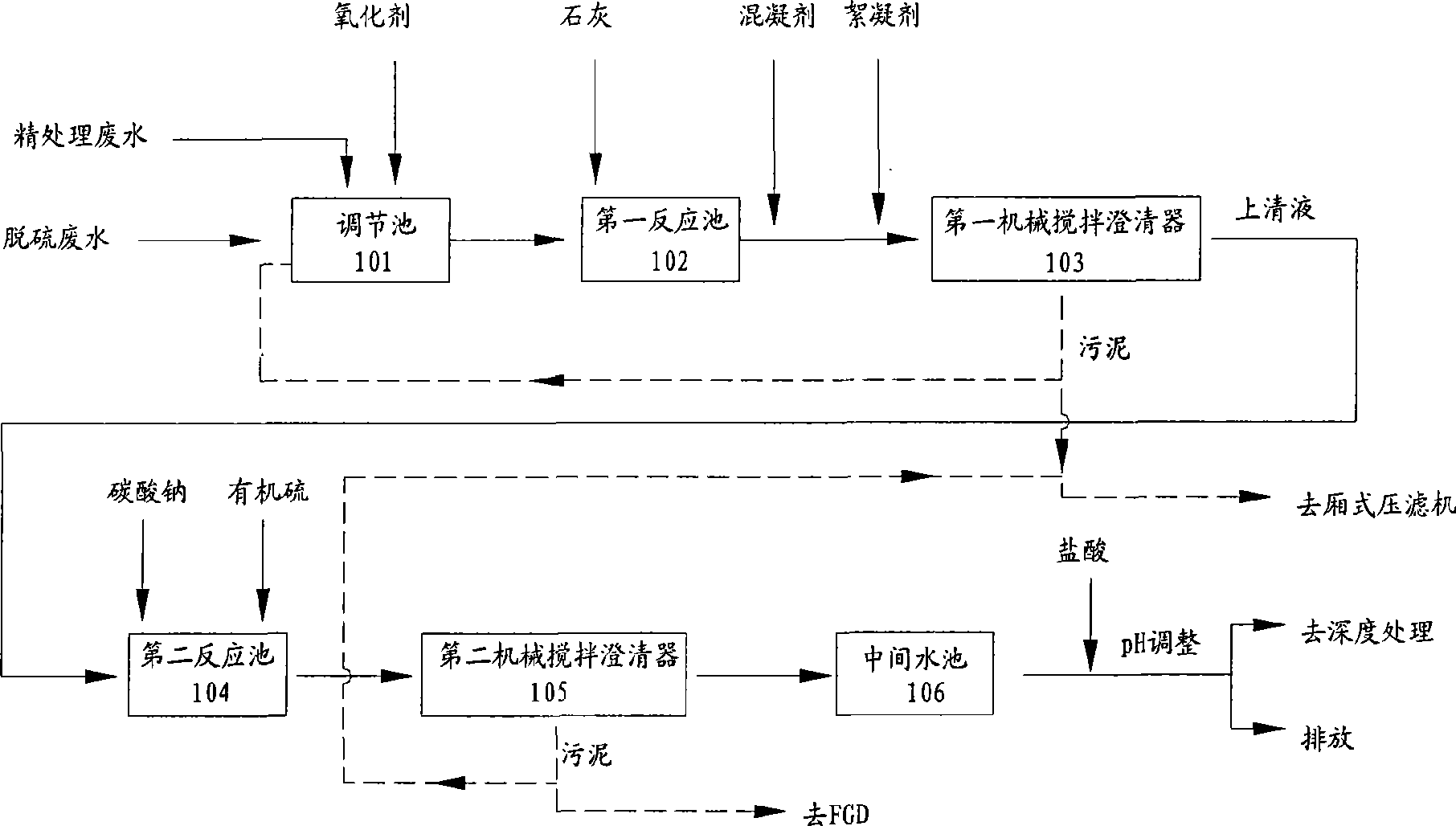

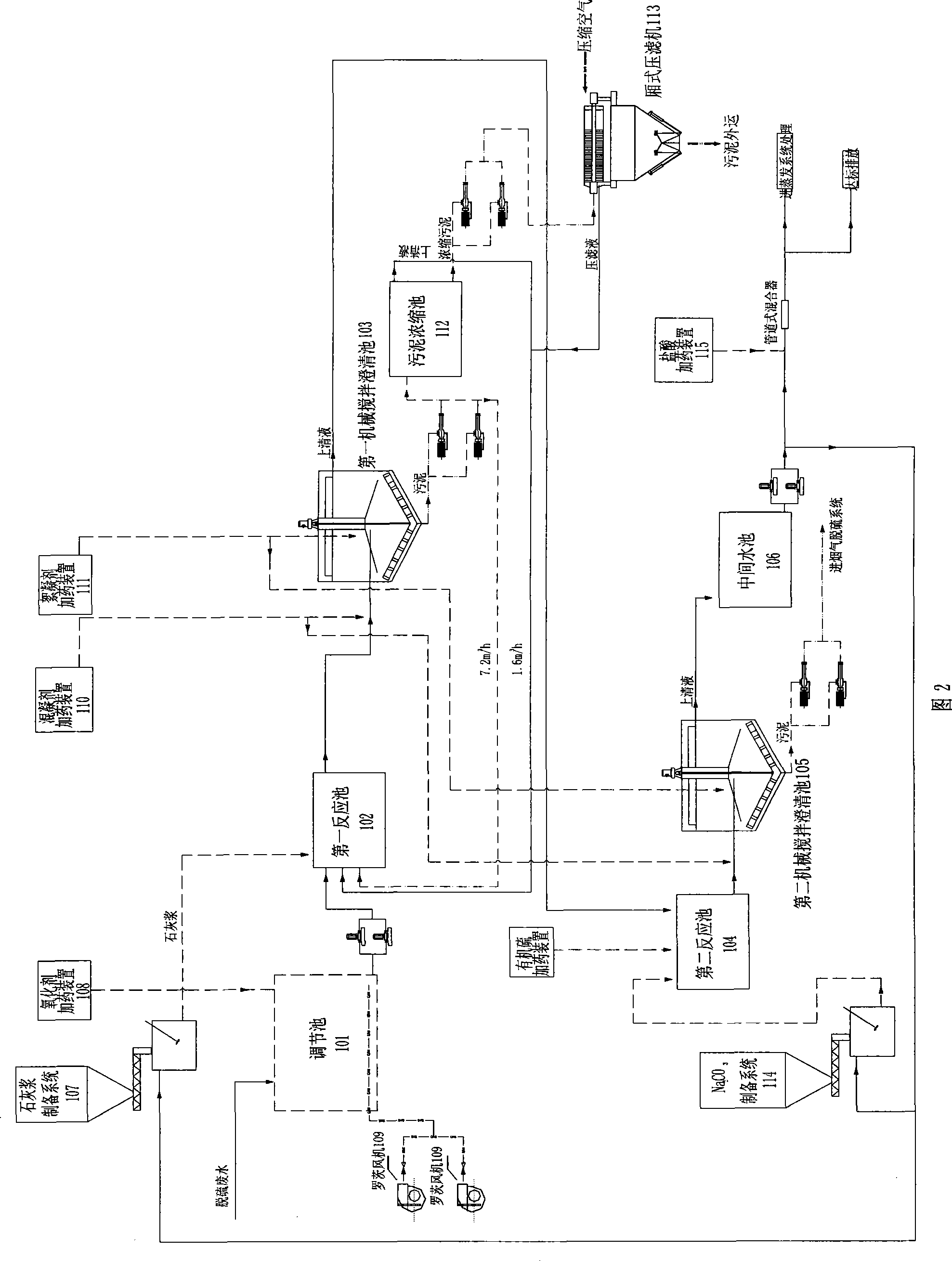

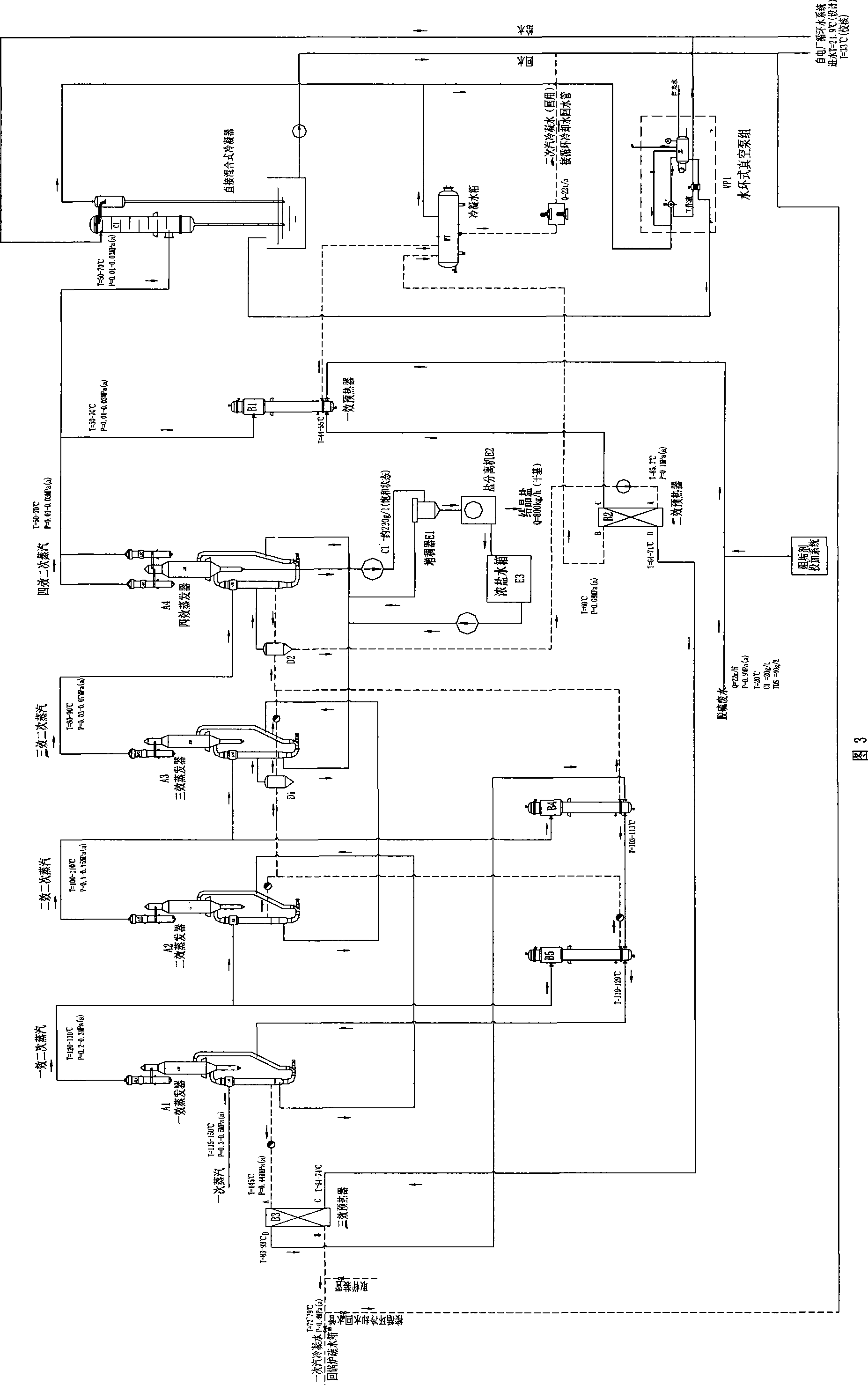

[0055] The power plant wastewater treatment system of the present invention includes a pretreatment system and an evaporation crystallization system connected. Access power plant wastewater at the inlet and outlet of the pretreatment system; first add lime (slaked lime Ca(OH) 2 and / or quicklime (CaO), after mixed reaction, add coagulants and flocculants (such as iron salt coagulants and PAM flocculants) to carry out coagulation and precipitation to remove most of SS, heavy metals, Mg in power plant wastewater 2+ , F - , and sulfate. In this process, in order to ensure that the COD and ammonia nitrogen of the wastewater can reach the standard, an oxidant can be added when necessary to remove organic pollutants and ammonia nitrogen; then, add Na 2 CO 3 , to remove excess Ca 2+ , so that the CaSO in the wastewater 4 The content is far less than its saturation concentration, reducing the formation of CaSO during evaporation 4 Possibility of fouling. Then, the pH value is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com