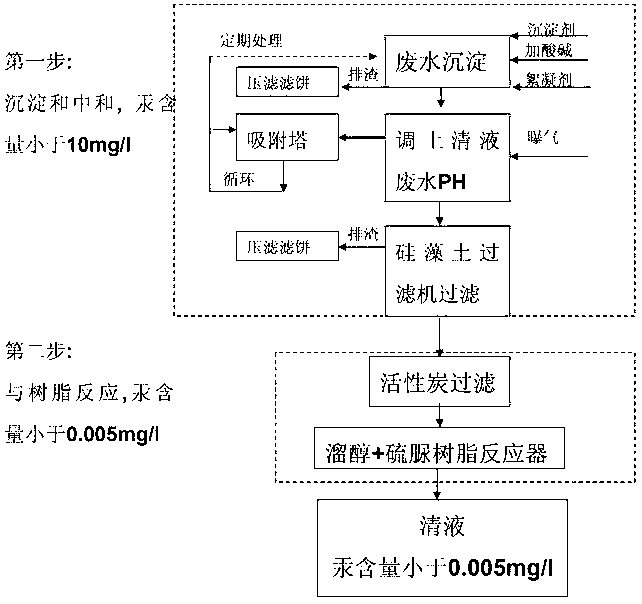

Method for treating mercury-containing wastewater during PVC (Polyvinyle Chloride) production through two-step process

A waste water and step method technology, which is applied in natural water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of high cost mercury removal technology and treatment methods, and achieve saving consumption, less power equipment, and adding less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Before the sample was processed, the mercury content was measured by cold atomic absorption method, which was alkaline wastewater with a mercury content of 3 mg / l and a pH value of 12.5. Then add 0.3% calcium chloride solution of the total amount of wastewater (calcium chloride concentration is 20%), stir for 30 minutes; then use acid to adjust the pH to 7-8, then slowly add PAC and PAM (total addition 30mg / l), after slow stirring for 30 minutes, stop, let stand for 1 hour, and discharge slag; then start aeration, and at the same time start the adsorption tower circulation pump to absorb the gas with sodium sulfide solution to entrain mercury, and stop aeration after 1 hour; use The diatomite filter will filter the treated water and send it to the next step. At this time, the mercury content of the system is measured by cold atomic absorption method and the result is <1mg / l.

[0022]The treated water is filtered by the diatomite filter and stored in the storage tank. A...

Embodiment 2

[0024] Before the sample treatment, the neutral wastewater with a mercury content of 30mg / l and a pH value of 6.5, first added the corresponding molar sodium sulfide solution according to 91% of the molar mercury content, and stirred for 30 minutes; then slowly added PAC and PAM (adding total amount of 30mg / l), stirring at a slow speed for 30 minutes, stop, let stand for 1 hour, and discharge slag; then start aeration, and start the adsorption tower circulation pump at the same time to absorb the gas with sodium sulfide solution to entrain mercury. After 1 hour, stop Aeration; use a diatomaceous earth filter to filter the treated water and send it to the next step. At this time, the mercury content in the system is measured by cold atomic absorption method and the result is <2mg / l.

[0025] The clear liquid filtered by the diatomite filter is stored in the storage tank, and the treated water passes through the activated carbon filter in series, and then through the mercaptan re...

Embodiment 3

[0027] Before the sample treatment, the acid wastewater with a mercury content of 120mg / l and a pH value of 2.5, first added the corresponding molar sodium sulfide solution according to 95% of the molar mercury content, and stirred for 30 minutes; then adjusted the pH value to 6-8, At this time, slowly add PAC and PAM (the total amount added is 30mg / l), stop stirring after 30 minutes at a slow speed, let it stand for 1 hour, and discharge the slag; then start aeration, and at the same time start the adsorption tower circulation pump to absorb gas with sodium sulfide solution After 1 hour, stop the aeration; filter the treated water with a diatomaceous earth filter and send it to the next step. At this time, the mercury content in the system is measured by cold atomic absorption method and the result is <5mg / l.

[0028] The clear liquid filtered by the diatomite filter is stored in the storage tank, and the treated water passes through the activated carbon filter in series, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com