Method for forming pad structure

A pad and graphic transfer technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of time-consuming production cost and complicated process flow, and achieve the effect of simple process, good compatibility, and time-saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

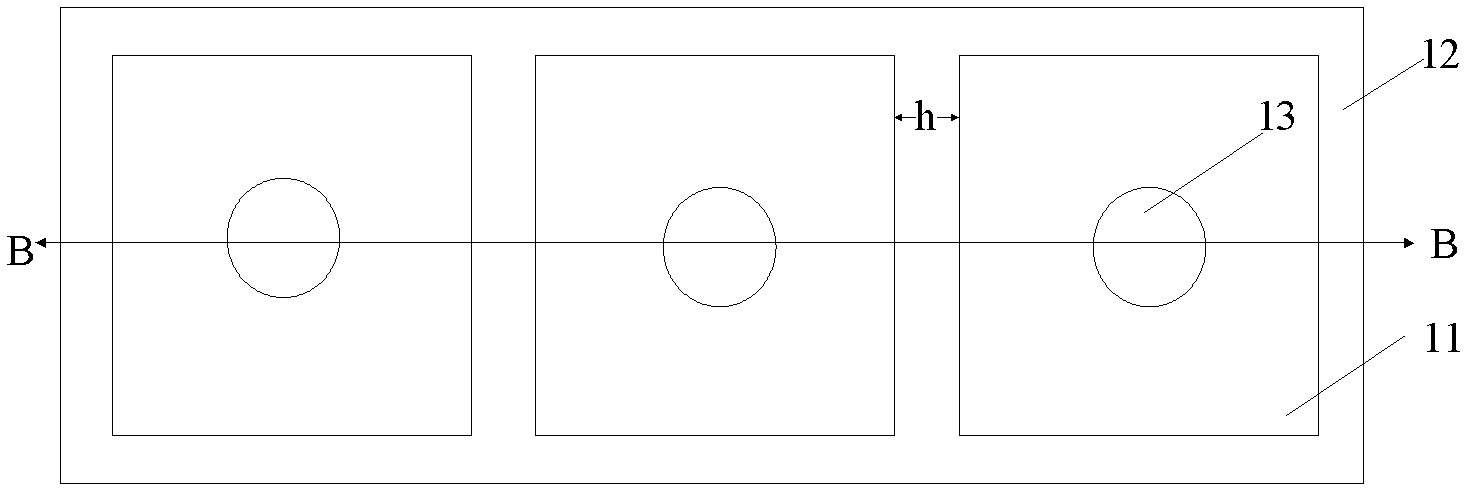

[0061] The following combination Figure 7 The flow chart of the method for forming the pad structure shown in the flowchart describes in detail how to form the pad structure provided by the first embodiment of the present invention.

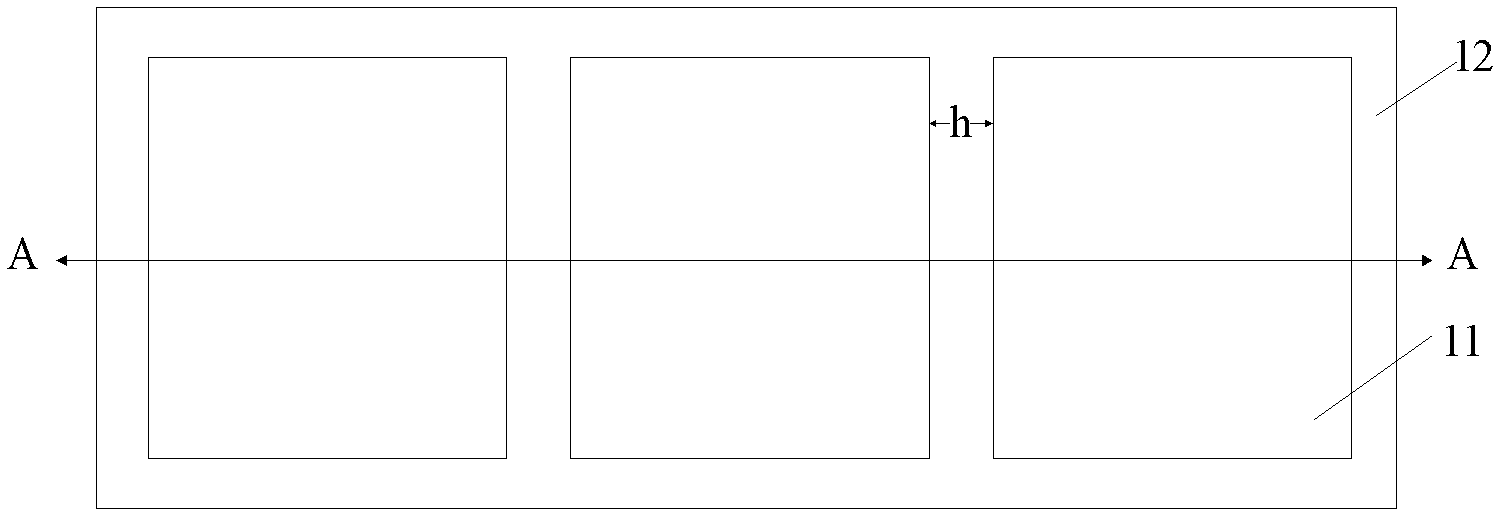

[0062] Firstly, step S21 is executed to provide a substrate 20 . Structural cross-section as Figure 8 As shown, there are three aluminum pads 21 on the substrate 20 . The substrate 20 includes a device structure, and the device structure is electrically connected to the aluminum pad 21 as required.

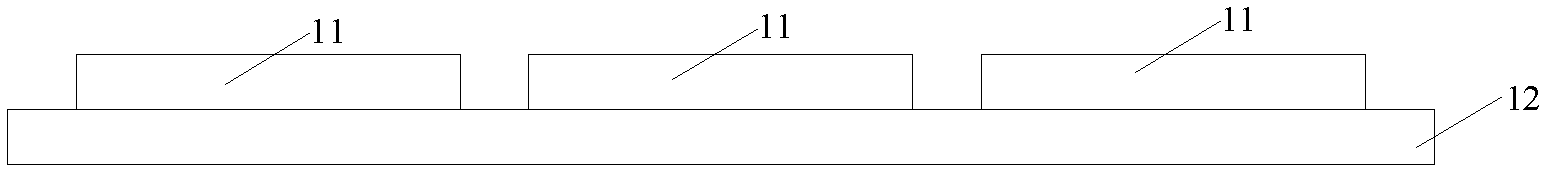

[0063] Executing step S22, forming a first protective layer 22 on the substrate 20 and the aluminum pad 21, the formed structure is as follows Figure 9 shown. The first protective layer 22 is an insulating material, which may be photoresist, such as photosensitive polyimide. Polyimide is an oily material, its hydrophobic property can isolate water vapor, and its C-N structure can absorb radiated light, so as to prevent the devices on the alum...

no. 2 example

[0085] Embodiment 2 of the present invention provides another method for forming a pad structure, the flow chart is as follows Figure 18 shown. The following pair Figure 18 The flow shown is described in detail.

[0086] Firstly, step S41 is performed to provide a substrate 20, on which there are three aluminum pads 21, the structural cross-sectional view is as follows Figure 8 shown. This step is the same as step S21 in the first embodiment.

[0087] Execute step S42, forming a protective layer 29 on the substrate 20 and the aluminum pad 21, the structural cross-sectional view is as follows Figure 9 shown. in, Figure 9 The number 22 in is the second protective layer. Since the protective layer is only formed once in the second embodiment, those skilled in the art need to understand Figure 9 The reference number 22 is replaced by 29; the formation method and material of the protective layer 29 in this step are the same as the formation method and material of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com