Preparation method of graphene, graphene and application of graphene

A graphene and graphite technology, applied in the field of carbon material preparation, to achieve the effects of excellent thermal conductivity, uniform thickness and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The graphene oxide is prepared by the Hummers method to obtain a graphene oxide-sulfuric acid solution, wherein the mass ratio of graphene oxide to 65 wt.% sulfuric acid is 1:300. Add reduced iron powder to the solution (the mass ratio of reduced iron powder to graphene oxide is (6:1), and react for 6 hours at 25°C. After the reaction is complete, wash with deionized water for several times to neutral, and dry under normal pressure for 12 hours. Partially reduced graphene oxide powder is obtained. The obtained powder is placed in a 700W microwave emitting device and reacted for 10 seconds to obtain graphene.

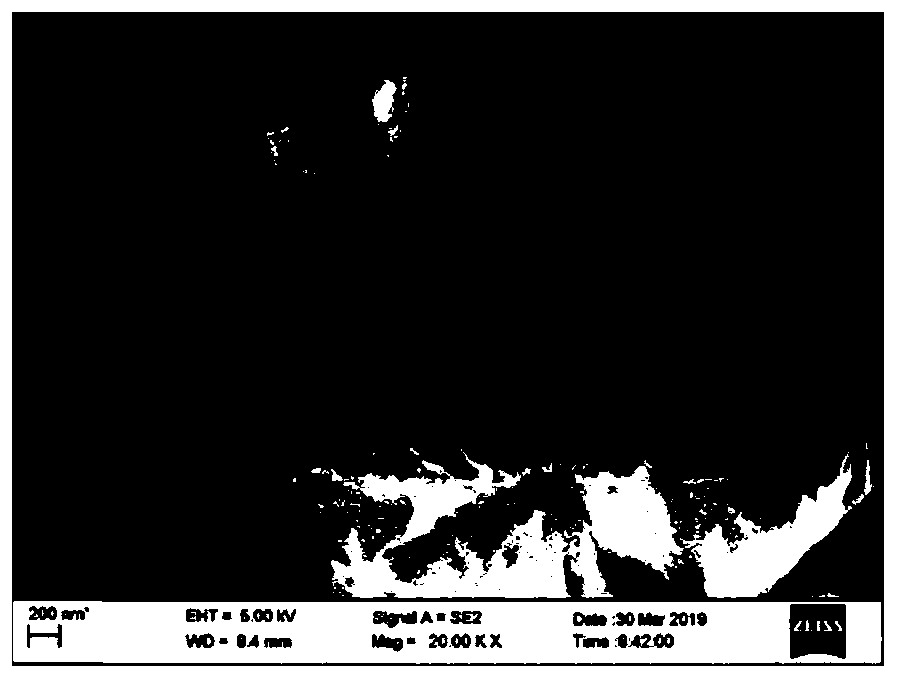

[0033] Such as figure 1 As shown, the prepared graphene is 2nm thick.

[0034] Further tests show that the radial thermal conductivity of the prepared graphene measured by laser flash method is 1531W / m·K; the prepared graphite has a conductivity of 134S / m measured by a comprehensive physical property measuring instrument.

Embodiment 2

[0036] Graphene oxide is prepared by Brodies method to obtain graphene oxide-nitric acid solution, wherein the mass ratio of graphene oxide to 50w.t% nitric acid is 1:20. Add reduced iron powder (the mass ratio of reduced iron powder to graphene oxide is 4:1) into the solution, and react for 4 hours at 20°C. After the reaction is completed, it is washed several times with deionized water to neutrality, and freeze-dried for 24 hours to obtain partially reduced graphene oxide powder. Place the obtained powder in a 500W microwave emitting device and react for 30 seconds to obtain graphene.

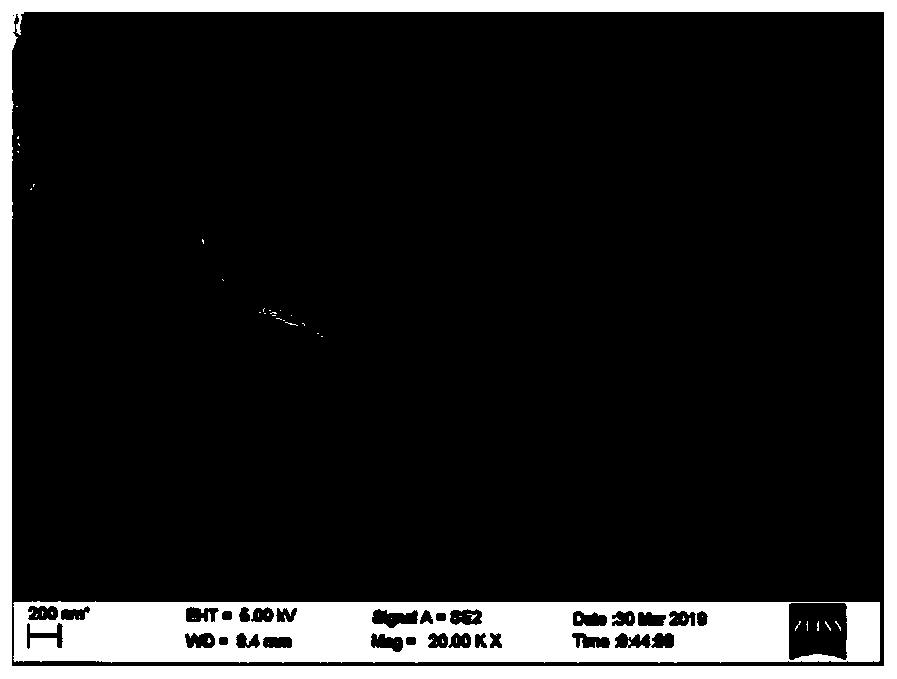

[0037] Such as figure 2 As shown, the thickness of the prepared graphite nanosheet is 1.5 nm.

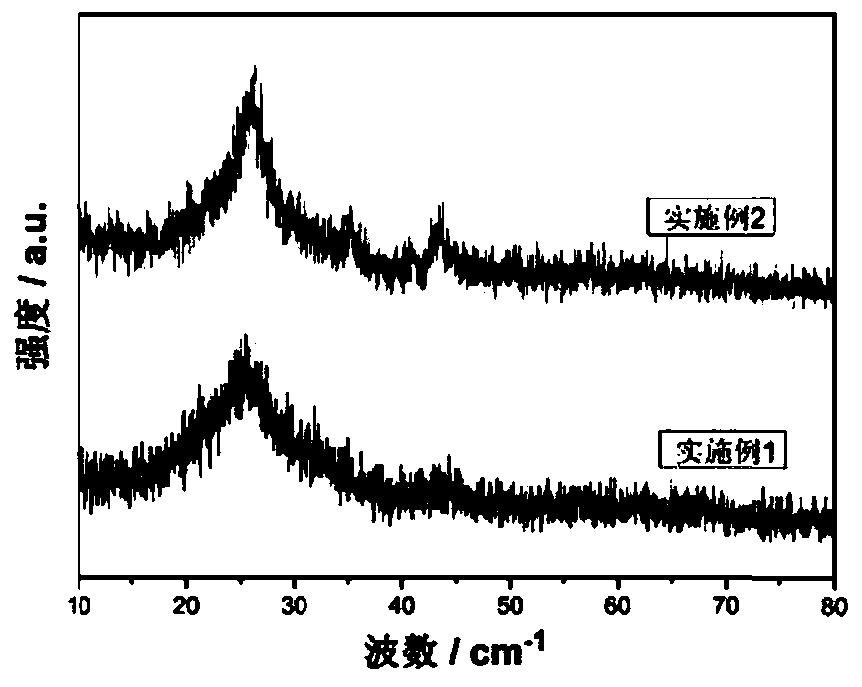

[0038] Such as image 3 As shown, the XRD diffraction spectra of the graphene prepared in Examples 1 to 2 show that the (002) plane diffraction peak of graphene appears at 2θ=25°, which proves that graphene oxide is successfully reduced to graphene, which has the characteristics of graphene.

[0039] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com