Non-oxidized nano copper soldering paste for high-power chip packaging and preparation method of soldering paste

A chip packaging, high-power technology, used in welding equipment, manufacturing tools, welding media, etc., can solve the problem of poor electrical properties of nano-copper sintered body, mechanical properties of connection structures need to be improved, and nano-copper solder paste The scope of application is narrowed, etc. problems, to achieve the effect of simple and easy-to-obtain equipment, high service temperature and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method for an oxidation-free nanometer copper solder paste used as high-power chip packaging, comprising the following steps:

[0030] (1) Configure a polyol solution mixed with a certain concentration of copper source and dispersant, and heat it to a certain temperature.

[0031] (2) Configure a polyol solution with a certain concentration of reducing agent and heat it to a certain temperature.

[0032] (3) The initial copper nanoparticles were synthesized by chemical reduction method.

[0033] (4) Prepare an anhydrous ethanol solution of a certain concentration of organic acid.

[0034] (5) Soak the synthesized primary copper nanoparticles in an organic acid solution of ethanol to remove the oxide layer on the surface of the primary copper nanoparticles.

[0035] (6) Mix the prepared surface oxide-free copper nanoparticles with an organic solvent, and obtain an oxidation-free nano-copper solder paste after stirring by mechanical stirring and a small pl...

Embodiment 1

[0052] Implementation example 1 A kind of oxidation-free nano-copper solder paste used as high-power chip packaging and its preparation method

[0053] Take 1 g of copper nanoparticles prepared by the chemical reduction method, mix with 2.5% formic acid in absolute ethanol solution, let stand for 10 min until the solution is separated, and centrifuge the copper nanoparticles. The precipitated copper nanoparticles are washed several times with absolute ethanol, and after the upper liquid becomes colorless and transparent, the nanoparticles are centrifugally precipitated to obtain oxide-free copper nanoparticles.

[0054] Mix the oxide-free copper nanoparticles and ethylene glycol at a mass ratio of 1:1, mechanically stir for 40 minutes, and then fully stir with a small planetary gravity mixer. After 50 seconds, an oxidation-free nano-copper solder paste is obtained.

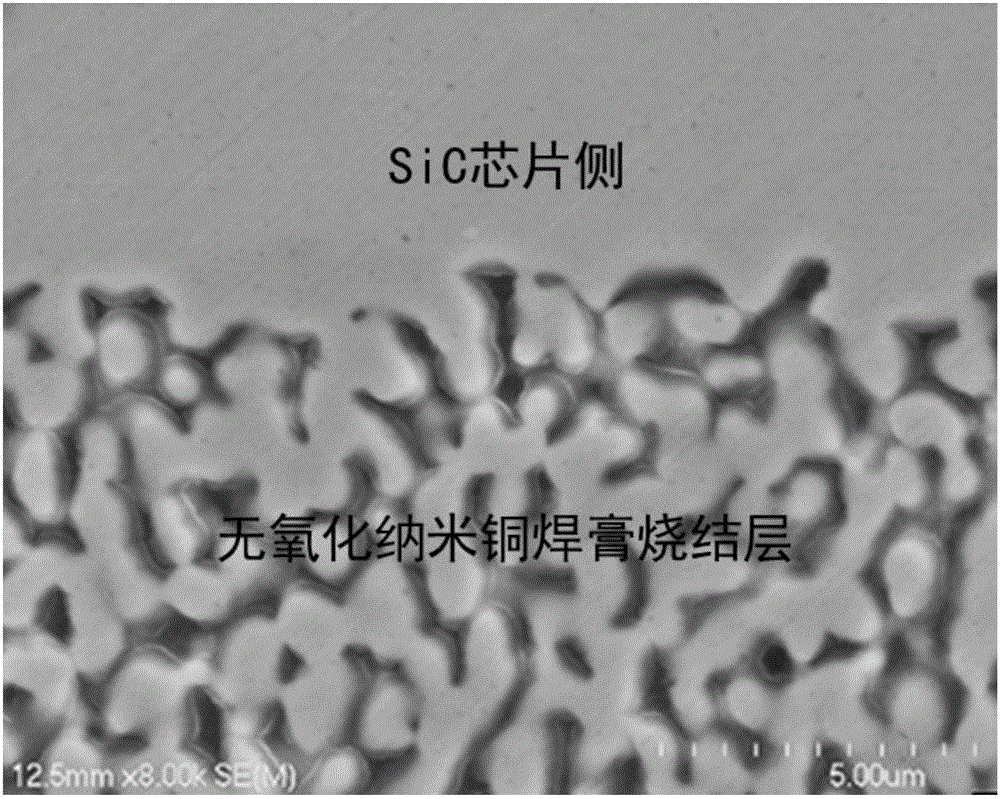

[0055] Deposit the non-oxidative nano-copper paste on the DBC substrate by stencil printing, after drying, asse...

Embodiment 2

[0056] Implementation example 2 A kind of oxidation-free nano-copper solder paste used as high-power chip packaging and its preparation method

[0057] Take 1 g of copper nanoparticles prepared by the chemical reduction method, mix with 5% formic acid in absolute ethanol solution, let stand for 10 min until the solution is separated, and centrifuge the copper nanoparticles. The precipitated copper nanoparticles are washed several times with absolute ethanol, and after the upper liquid becomes colorless and transparent, the nanoparticles are centrifugally precipitated to obtain oxide-free copper nanoparticles.

[0058] Mix the oxide-free copper nanoparticles and ethylene glycol at a mass ratio of 1:1, mechanically stir for 40 minutes, and then fully stir with a small planetary gravity mixer. After 50 seconds, an oxidation-free nano-copper solder paste is obtained.

[0059] Deposit the non-oxidative nano-copper paste on the DBC substrate by stencil printing, after drying, assemb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com