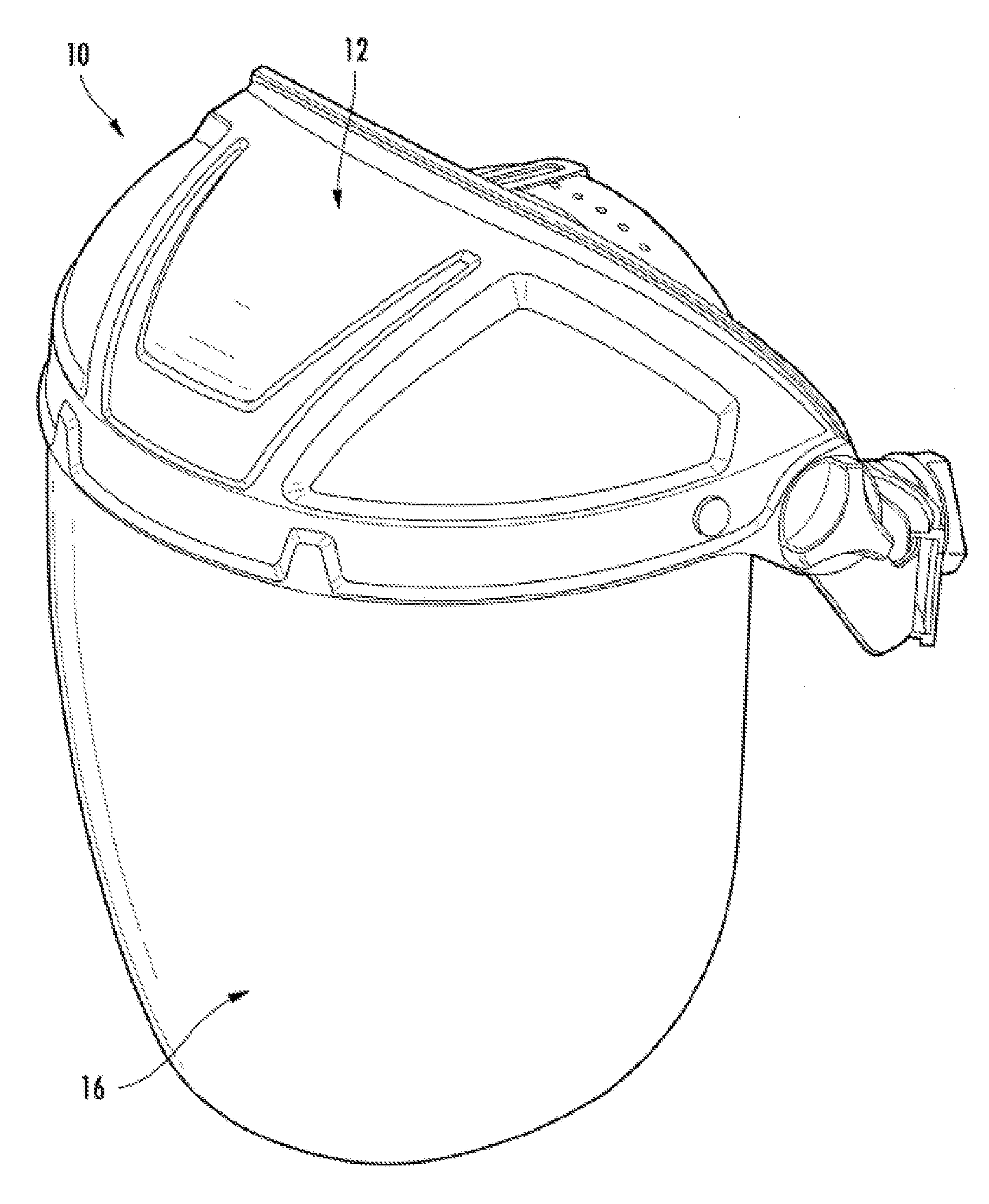

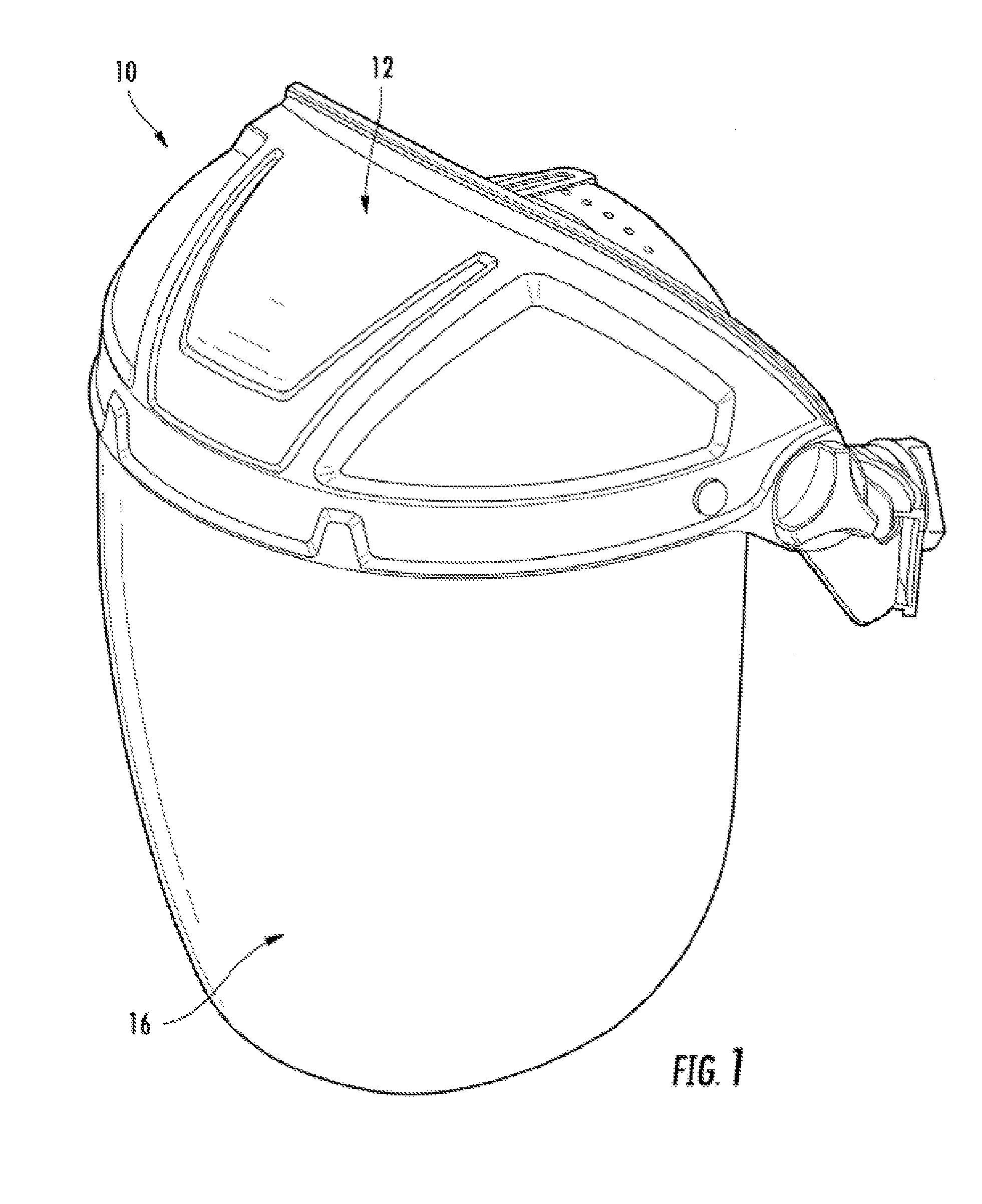

Electric-arc resistant face shield or lens including ir-blocking inorganic nanoparticles

a technology of inorganic nanoparticles and face shields, applied in the direction of coatings, mechanical equipment, capacitors, etc., can solve the problems of immediate fatal burns, electric arc flashes, electric arcs that are extremely dangerous for electric workers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0022]Cs0.33WO3 tungsten bronze powder can be prepared by homogeneously mixing an aqueous solution of soluble tungsten and cesium salts, e.g. ammonium tungstate and cesium acetate, followed by drying and high temperature treatment in a reducing / inert gas atmosphere to form the final crystalline tungsten bronze nanoparticles.

[0023]A homogenous dispersion of the tungsten nanoparticles are then prepared in a liquid solvent medium, e.g. toluene, using a wet milling method with small diameter grinding media. Typically the milling media would be zirconia-based and have a diameter of less than 0.3 mm. A horizontal wet media mill would be suitable for this application. A dispersing agent, e.g. a polyacrylate, would be typically added at this stage to improve the dispersion of the powder material and to yield a stable solvent dispersion of the nanoparticle. Other materials including inorganic particles, organic dyes, heat stabilizers and UV absorbers can be added at this stage or later.

[0024...

example 2

[0027]Even lower concentrations of tungsten oxide nanoparticles could be used for this application, for example 0.1% by weight and lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

| composition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com