Desulfurization wastewater recycling process and implementation device

A desulfurization wastewater and recycling technology, which is applied in descaling and water softening, gaseous effluent wastewater treatment, inorganic chemistry, etc., can solve immature problems, reduce chloride ion content, realize resource utilization, and promote volatilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

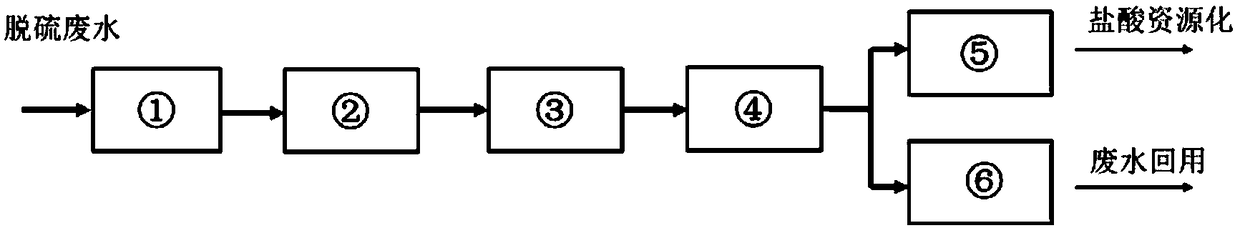

[0033] see figure 1 and figure 2 , a process for resource recycling of desulfurization wastewater in this embodiment, comprising the following steps:

[0034] ① Pretreat the desulfurization wastewater discharged from the desulfurization tower. The pretreatment method is to add chemical solution, partially soften, remove heavy metals, and separate solid and liquid;

[0035] ② Flocculation and clarification of pretreated desulfurization wastewater;

[0036] ③ Add quantitative concentrated sulfuric acid to the clarified desulfurization wastewater, and mix the desulfurization wastewater with strong acid;

[0037] ④Wastewater is treated by gas-liquid mass transfer process;

[0038] ⑤ Collect the hydrogen chloride gas produced in the gas-liquid mass transfer process and convert it into hydrochloric acid with higher purity, which can be used as a resource;

[0039] ⑥ After the gas-liquid mass transfer process, the treated wastewater is added with milk of lime to adjust the pH to...

Embodiment 2

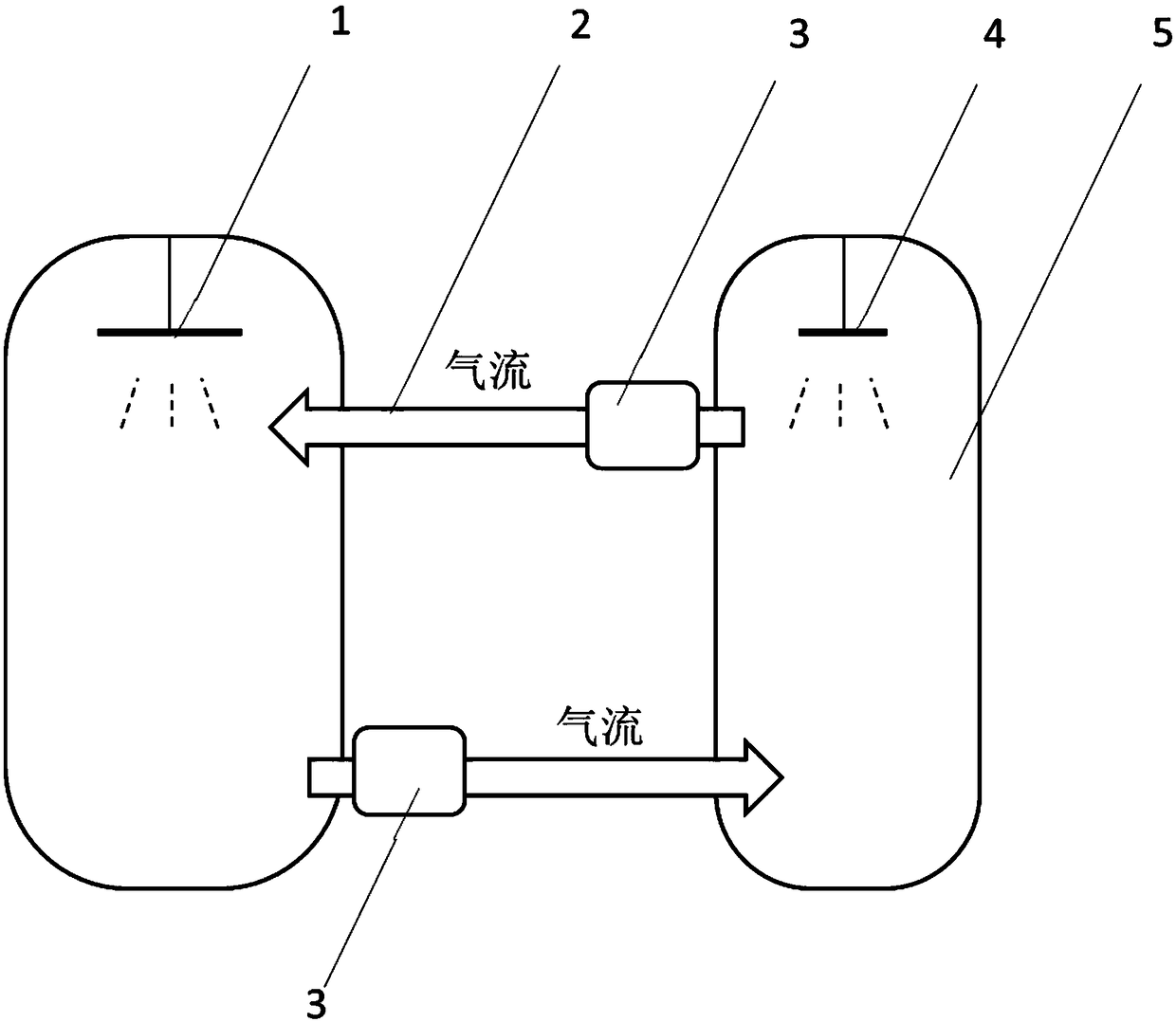

[0050]This embodiment 2 also adopts the same process as that of embodiment 1. After the waste water is clarified, its chloride ion content is measured, and a corresponding amount of concentrated sulfuric acid is added to the waste water. Further, the waste water enters the spray tower 1, and the low-quality steam or waste heat air in the factory area is blown into the tower, and the gas and liquid flow in the same direction. The gas flow loaded with hydrogen chloride enters another spray tower 5, is absorbed by the spray liquid, and the gas flow recirculates into the waste water spray tower 1 to carry out circulation treatment of gas-liquid mass transfer. Industrial water can be used for the absorption liquid, which is discharged after reaching a certain concentration and filled with new absorption liquid. Further, after the waste water circulates and stays in the spray tower 5 for a certain period of time, it is discharged and an alkaline agent is added to adjust the pH of th...

Embodiment 3

[0052] After the wastewater is clarified, a corresponding amount of concentrated nitric acid is added to the wastewater. Further, the waste water enters the spray tower 1, and air is blown into the tower, and the gas and liquid flow in the same direction. The gas flow loaded with hydrogen chloride enters another spray tower 5, is absorbed by the spray liquid, and the gas flow recirculates into the waste water spray tower 1 to carry out circulation treatment of gas-liquid mass transfer. Sodium hydroxide solution is used as the absorption liquid, and sodium hydroxide caustic soda or liquid caustic soda is added after the absorption liquid reaches a certain pH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com