Pickling tank

A technology of pickling tank and tank body, applied in the field of pickling tank, can solve problems such as safety hazards and production accidents, and achieve the effect of reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

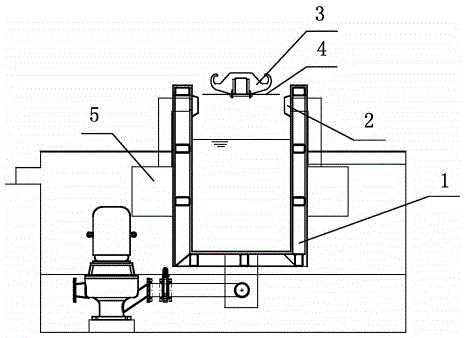

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

[0013] The invention provides a pickling tank, comprising a tank body and a hook, the tank body is provided with a notch, the opening of the notch faces upward, the hook is provided with a tank cover, and the side wall of the tank body is With suction port. Compared with the prior art, when pickling copper rods, the copper rods are hoisted to the tank through the hook under the driving, and the staff often forget to cover the tank cover, due to the open tank ,There are security risks. In the present invention, by installing the tank cover on the hook, after the staff hoist the bar to the tank body through the hook, the tank cover on the hook can play a protective role without removing the hook, reducing potential safety hazards . At the same time, the tank cover also plays the role of drainage, leading the acid mist to the side wall of the tank body, so that the acid mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com