Electromagnetic induction evaporation concentrator

An electromagnetic induction and concentrator technology, applied in cascade evaporators, evaporator accessories, evaporation, etc., can solve the problems of inconvenient equipment maintenance, large compressor volume and high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

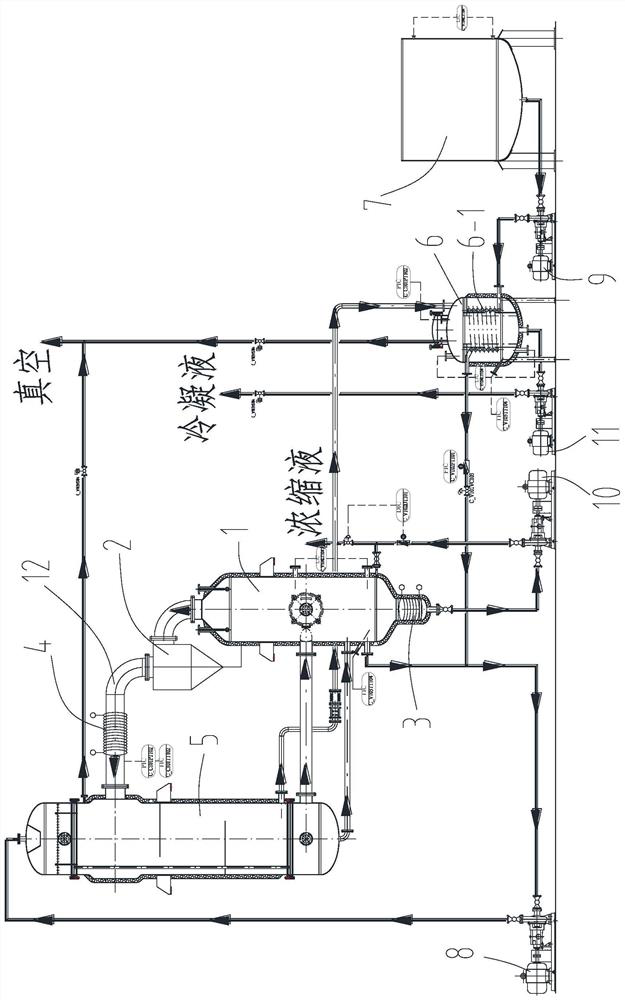

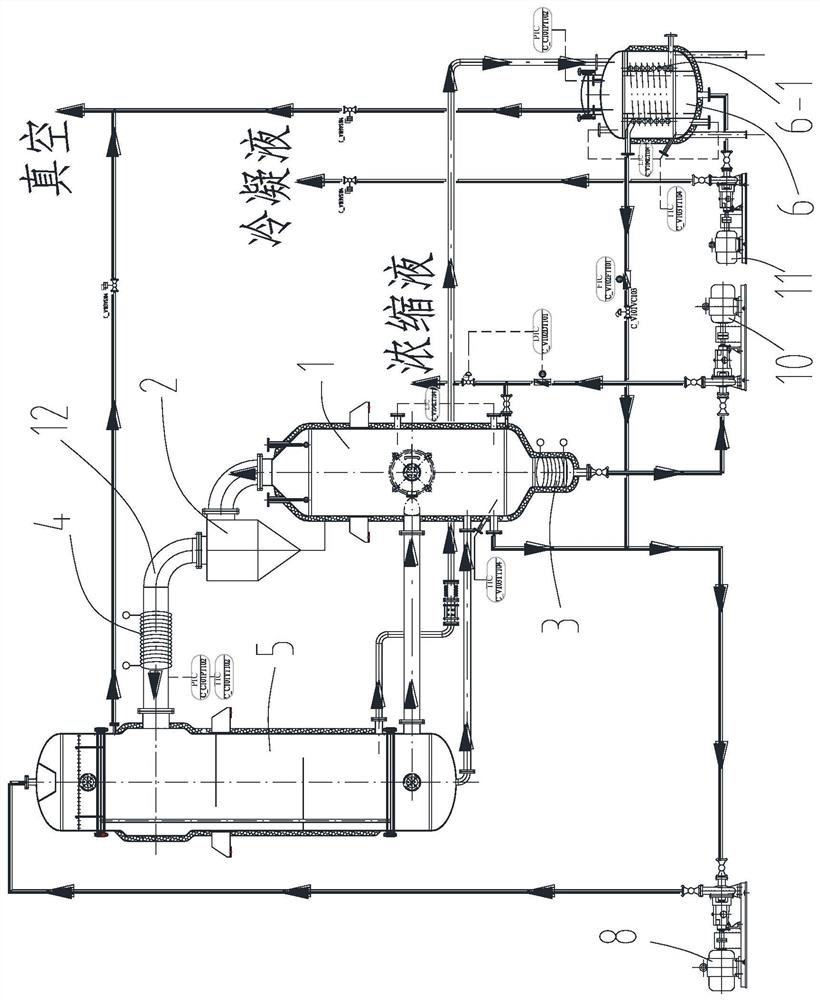

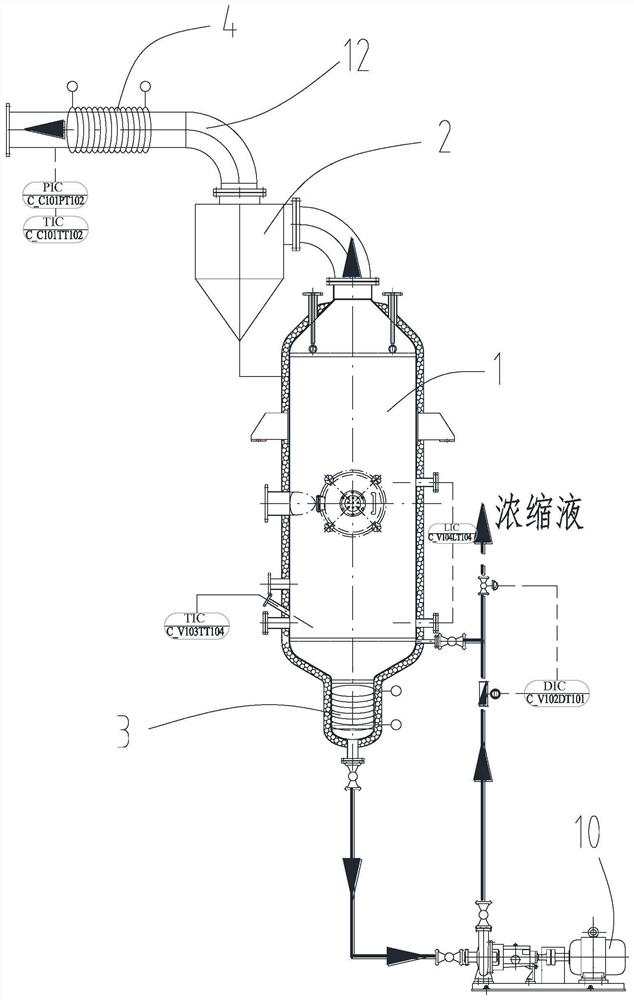

[0033] Such as Figure 1~4As shown, an electromagnetic induction evaporation concentrator includes an evaporation chamber 1, a separator 2, a first heating device 3 and a second heating device 4, and the first heating device 3 and the second heating device 4 all include magnetically conductive A round tube 3-1 and an induction coil 3-2, the induction coil 3-2 is wound on the magnetically conductive round tube 3-1, the induction coil 3-2 is electrically connected to an AC induction power supply, and the AC induction power supply is an induction coil 3-2 provides an alternating current, and the alternating current flowing through the induction coil 3-2 generates an alternating magnetic field passing through the magnetic conducting tube 3-1, and the magnetic field causes the magnetic conducting tube 3-1 to generate eddy current for heating; The magnetically conductive circular tube 3-1 of the first heating device 3 is set in the lower part of the evaporation chamber 1, and the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com