Three-head groove machining die for three-way pipe fitting

A technology for three-way pipe fittings and processing molds, which is applied in the field of mechanical processing, can solve the problems of slow processing speed, time-consuming, and inability to improve production efficiency of manual pressing parts, so as to achieve crack quality assurance, reduce production costs, and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

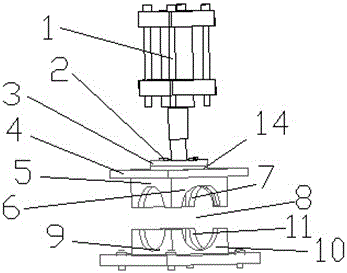

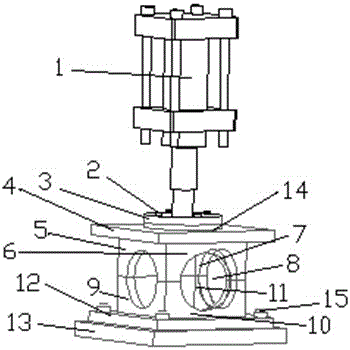

[0013] The present invention will be further described below in conjunction with the accompanying drawings of a three-way break processing mold for a three-way pipe fitting of the present invention.

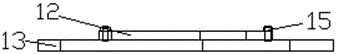

[0014] Such as figure 1 , figure 2 , image 3 As shown, a three-way break processing mold for three-way pipe fittings of the present invention includes: hydraulic oil top (1); hexagon socket head bolt (2); link plate (3); mold upper template (4); Plate 1 (5); Tee upper baffle 2 (6); Tee upper baffle 3 (7); Tee lower baffle 1 (9); Tee lower baffle 2 (10); Tee lower baffle Plate three (11); three-way upper baffle one (5), three-way upper baffle two (6), three-way upper baffle three (7) and three-way lower baffle one (9), three-way lower baffle The cavity (8) for processing the tee surrounded by the plate two (10) and the three-way lower baffle plate (11); the mold lower template (12); the notch machining platform (13); the mold link plate (14 ); lag bolts (15).

[0015] The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com