Antibacterial dust-adsorption-resistant composite plastic master batch and preparation method thereof

A plastic masterbatch and composite technology, which is applied in the field of plastic masterbatch, can solve the problems that it cannot completely replace spray-free, does not have dust absorption resistance, and the metal texture of glass-based pearlescent pigments is not strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

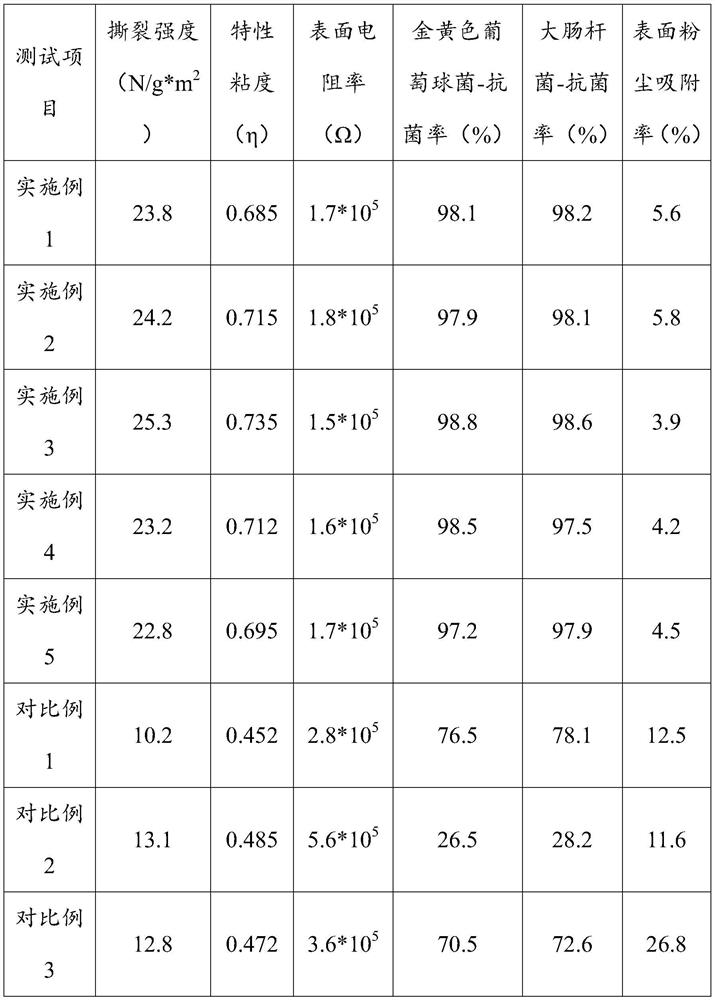

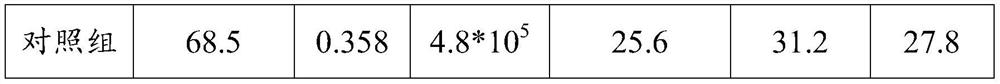

Examples

Embodiment 1

[0043] An antibacterial and dust-resistant adsorption composite plastic masterbatch, the antibacterial and dust-resistant adsorption composite plastic masterbatch is made of the following raw materials in parts by weight:

[0044] 45 parts of polypropylene, 25 parts of filler, 5 parts of plasticizer, 4 parts of lubricant, 3 parts of polyhydroxy chemical coupling agent, 3.5 parts of modification additive, 1 part of compound antioxidant, 1 part of compound antibacterial agent, compound antibacterial 1 part of electrostatic agent, 1 part of light stabilizer, 1 part of toughening agent, 2 parts of hydroxymethyl cellulose, 1 part of impact modifier, 4 parts of porous ceramic preform, 1 part of nano flame retardant, carbon nano Fiber 4 servings.

[0045] The modification aid is made from the following raw materials in parts by weight:

[0046] Diethylenetriaminopropyl trimethoxysilane 35 parts, modified triethanolamine 15 parts, maleic anhydride 10 parts, cocamidopropyl betaine 15 ...

Embodiment 2

[0072] An antibacterial and dust-resistant adsorption composite plastic masterbatch, the antibacterial and dust-resistant adsorption composite plastic masterbatch is made of the following raw materials in parts by weight:

[0073] 46 parts of polypropylene, 28 parts of filler, 5.5 parts of plasticizer, 4.5 parts of lubricant, 3.5 parts of polyhydroxy chemical coupling agent, 3.8 parts of modification additive, 1.2 parts of composite antioxidant, 1.5 parts of composite antibacterial agent, composite antibacterial 1.5 parts of electrostatic agent, 1.2 parts of light stabilizer, 1.2 parts of toughening agent, 2.5 parts of hydroxymethyl cellulose, 1.5 parts of impact modifier, 4.5 parts of porous ceramic preform, 1.5 parts of nano flame retardant, carbon nano Fiber 4.5 parts.

[0074] The modification aid is made from the following raw materials in parts by weight:

[0075] 36 parts of diethylenetriaminopropyltrimethoxysilane, 16 parts of modified triethanolamine, 12 parts of mal...

Embodiment 3

[0101] An antibacterial and dust-resistant adsorption composite plastic masterbatch, the antibacterial and dust-resistant adsorption composite plastic masterbatch is made of the following raw materials in parts by weight:

[0102] 47 parts of polypropylene, 30 parts of filler, 6 parts of plasticizer, 5 parts of lubricant, 4 parts of polyhydroxy chemical coupling agent, 4 parts of modification additive, 1.5 parts of composite antioxidant, 2 parts of composite antibacterial agent, and 2 parts of composite antibacterial agent 2 parts of electrostatic agent, 1.5 parts of light stabilizer, 1.5 parts of toughening agent, 3 parts of hydroxymethyl cellulose, 2 parts of impact modifier, 5 parts of porous ceramic preform, 2 parts of nano flame retardant, carbon nano Fiber 5 servings.

[0103] The modification aid is made from the following raw materials in parts by weight:

[0104] 40 parts of diethylenetriaminopropyltrimethoxysilane, 17 parts of modified triethanolamine, 15 parts of mal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com