Preparation method of high-throughput graphene oxide/polyimide mixed matrix membrane material

A technology of mixed matrix membrane and polyimide matrix, which is applied in the field of preparation of high-throughput graphene oxide/polyimide mixed matrix membrane materials, can solve the problems of poor temperature resistance, poor plasticization resistance, and poor separation performance. Limit and other issues, to achieve the effect of high operating temperature, stable chemical structure, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

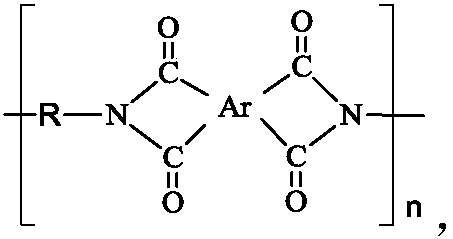

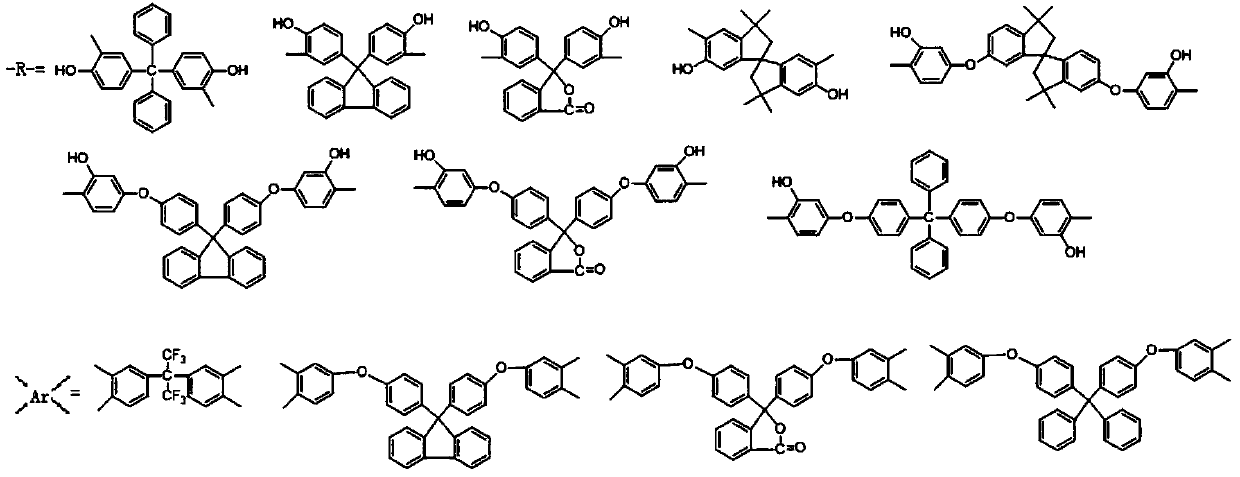

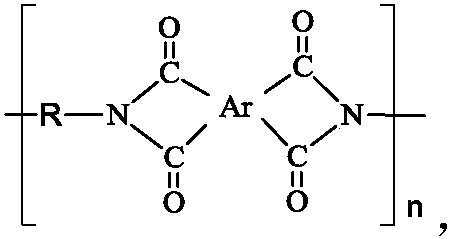

Method used

Image

Examples

Embodiment 1

[0039] First, aminated graphene was prepared according to conventional methods. Add a certain amount of aminated graphene and N,N-dimethylacetamide into a 250mL three-necked round-bottomed flask, and vibrate for 2 hours under the action of ultrasonic waves. Then, 0.01 mol of bis(3-hydroxy-4-aminophenyl)diphenylmethane was added, and reacted at 40° C. for 16 hours under mechanical stirring and nitrogen protection. After cooling down to room temperature, add 0.01mol 4,4'-(hexafluoroisopropylidene) diphthalic anhydride (6FDA), and continue to stir at room temperature for 18 hours to form a viscous aminated graphene / polyamic acid mixed solution. The solid content was 15% by weight. The solution was uniformly coated on a clean glass plate, and dried in a far-infrared drying oven at 80° C. and 150° C. for 6 hours respectively to obtain a composite material film. The content of aminated graphene in the composite film is 0.1wt%.

[0040] The composite material film containing 0.1wt...

Embodiment 2

[0042] First, aminated graphene was prepared according to conventional methods. Add a certain amount of aminated graphene and N,N-dimethylacetamide into a 250mL three-necked round-bottomed flask, and vibrate for 2 hours under the action of ultrasonic waves. Then, add 0.01mol 9,9-bis(4-aminophenyl)fluorene and 0.01mol 9,9-bis(3-amino-4-hydroxyphenyl)fluorene, and react at 70°C for 12 Hour. After cooling down to room temperature, add 0.02mol 4,4'-(hexafluoroisopropylidene) diphthalic anhydride (6FDA), and continue to stir at room temperature for 18 hours to form a viscous aminated graphene / polyamic acid mixed solution. The solid content was 15% by weight. The solution was uniformly coated on a clean glass plate, dried at 40°C for 24 hours, then removed, and then dried in a far-infrared oven at 80°C and 150°C for 6 hours to obtain a composite film. The content of aminated graphene in the composite material is 0.5wt%.

[0043] The composite material film containing 0.5wt% amin...

Embodiment 3

[0045] The preparation method of the composite material film in this embodiment is the same as in Example 2, and the difference from Example 2 is that the composite material film containing 0.5wt% aminated graphene is placed in a heating furnace, and nitrogen gas is fed into the gas flow rate. 100ml / min, the furnace temperature is raised to 250°C at 2°C / min, then raised to 550°C at 1°C / min, and maintained at this temperature for 1 hour, and the graphene oxide / polyimide mixture is obtained after natural cooling Matrix membrane material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com