A kind of ultrasonic heat-sealing film for preparing aircraft inner wall insulation sealing bag and preparation method thereof

An insulating sealing and thin film technology, which is applied in the field of ultrasonic heat sealing film and its preparation, can solve the problems of not being able to withstand extrusion, pressure, falling, and poor tensile resistance, and achieve stability, high chemical stability, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1: An ultrasonic heat-sealing film and its preparation method for preparing insulating and sealing bags on the inner wall of aircraft

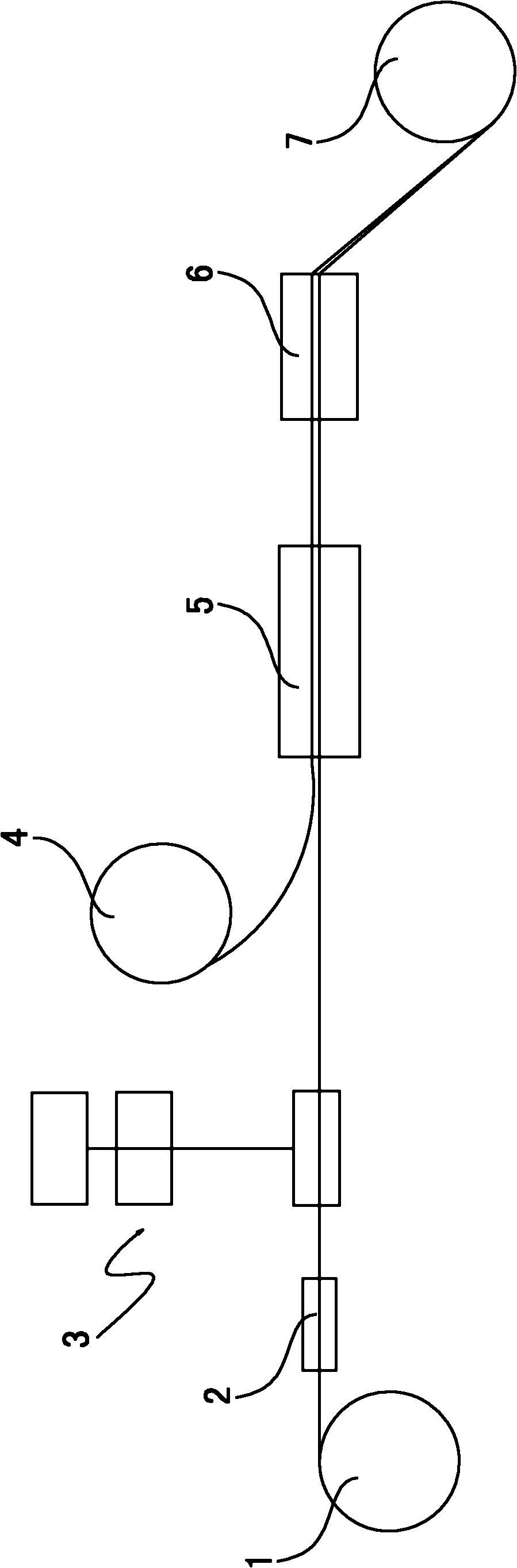

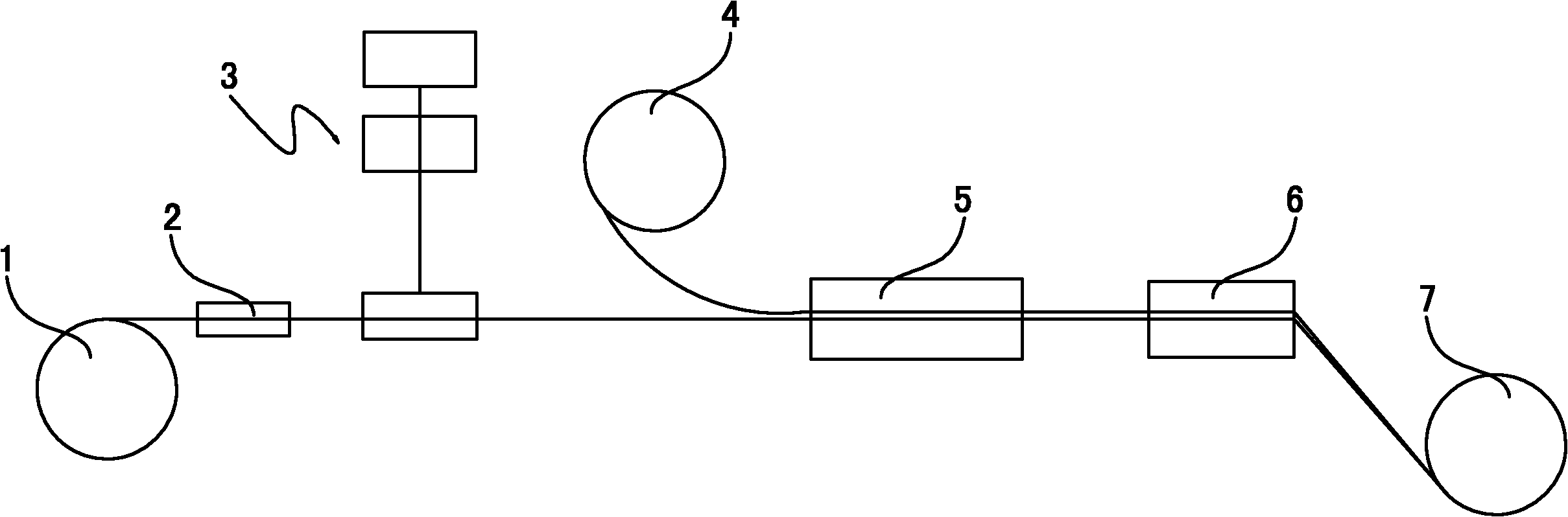

[0061] The processing device adopted in the present invention is as attached figure 1 shown. Install the polyimide film on the film substrate unwinding roller 1, the first power traction rail 2 pulls the polyimide film from the film substrate unwinding roller 1 at the speed set by the machine, and passes through the adhesive Coating device 3, the prepared ultrasonic heat-sealing polyurethane adhesive is coated on one surface of the polyimide film. The reinforced fiber web is installed on the reinforced fiber web unwinding roller 4, and the reinforced fiber web falls on the polyimide film with the ultrasonic heat-bonded polyurethane adhesive by its own weight, and is attached to the polyimide film after being wetted by the ultrasonic heat-bonded polyurethane adhesive. imide film. The polyimide film loaded with ultrasonic heat-...

Embodiment 2

[0064] Example 2: An ultrasonic heat-sealing film for preparing insulating and sealing bags on the inner wall of an aircraft and its preparation method

[0065] See attached figure 1 As shown, a polyimide film with a width of one meter and a thickness of 1 micron is installed on the film substrate unwinding roller 1, and the first power traction rail 2 will polyimide film from the film substrate unwinding roller 1 according to Pull out at a speed of 30 m / min. The coating head slit of the cast coater (adhesive coating device 3) was set to 40 microns. The solid content of the prepared ultrasonic heat-sealing polyurethane adhesive is 30%, the viscosity is 500 cps, and it flows into the trough of the coating head of the casting coating machine through the feed pump, and is coated on the polyimide film superior. The reinforced fiber web has a specific gravity of 0.011 ounces / cubic feet and is installed on the reinforced fiber web unwinding roller 4. The reinforced fiber web fall...

Embodiment 3

[0067] Example 3: An ultrasonic heat-sealing film and its preparation method for preparing insulating and sealing bags on the inner wall of aircraft

[0068] See attached figure 1 As shown, a polyimide film with a width of one meter and a thickness of 1 micron is installed on the film substrate unwinding roller 1, and the first power traction rail 2 will polyimide film from the film substrate unwinding roller 1 according to Pull out at a speed of 30 m / min. The mesh track of the texture coating machine (adhesive coating device 3) is 50 mesh, and the solid content of the prepared ultrasonic heat-sealing polyurethane adhesive is 50%, and the viscosity is 1200 cps, which is coated on the polyimide film . The reinforced fiber web has a specific gravity of 0.017 ounces / cubic feet and is installed on the reinforced fiber web unwinding roller 4. The reinforced fiber web falls on the polyimide film with ultrasonic heat-bonded polyurethane adhesive by its own weight, and is ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com