Modified cable filler and preparation method thereof

A cable filling and modification technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of shortening the service life of cables, economic losses, reducing the insulation level of insulating materials, etc., to prolong the service life, save resources, and improve electrical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

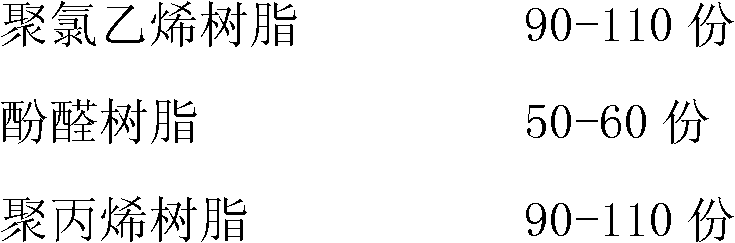

[0015] Embodiment 1: Modified cable filler, the parts by weight of its constituent raw materials are:

[0016]

[0017]

[0018] The preparation method of modified cable filler comprises the following steps:

[0019] (1) Weigh each raw material according to the weight of the constituent raw materials, mix them evenly, and load them into the extruder hopper, and the barrel temperature of the extruder is controlled at 130-190° C. to generate a molten mixture;

[0020] (2) Pour nitrogen gas into the molten mixture, take it out and pass it through a hot water tank at 75-95°C and a water tank at room temperature in sequence, and air-dry to obtain the finished product.

Embodiment 2

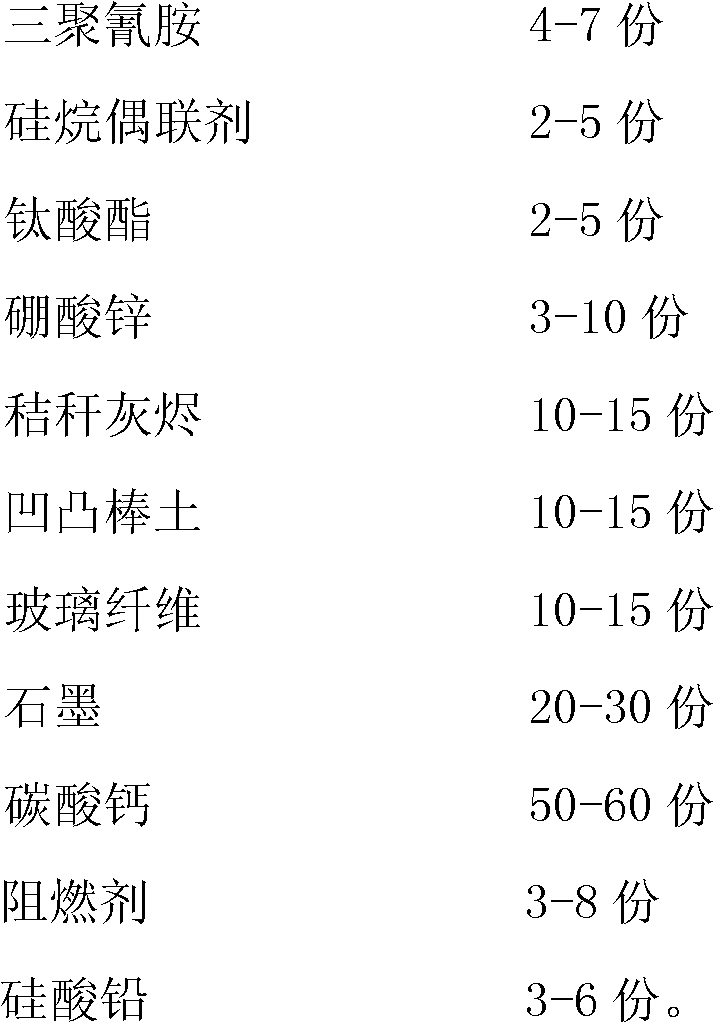

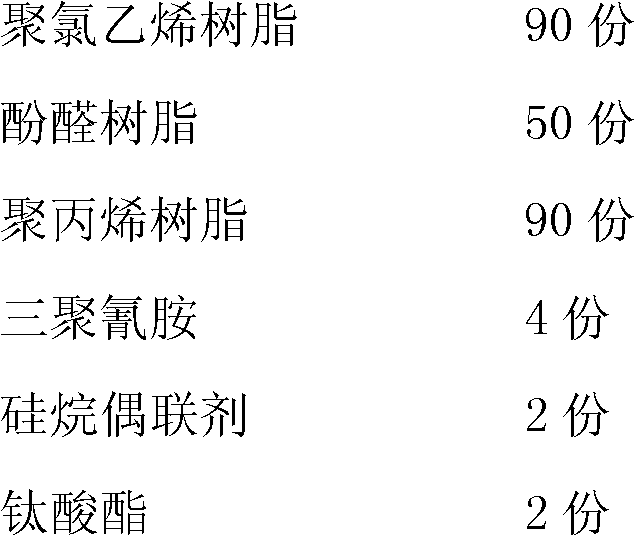

[0021] Embodiment 2: Modified cable filler, the parts by weight of its constituent raw materials are:

[0022]

[0023] The preparation method of modified cable filler comprises the following steps:

[0024] (1) Weigh each raw material according to the weight of the constituent raw materials, mix them evenly, and load them into the extruder hopper, and the barrel temperature of the extruder is controlled at 130-190° C. to generate a molten mixture;

[0025] (2) Pour nitrogen gas into the molten mixture, take it out and pass it through a hot water tank at 75-95°C and a water tank at room temperature in sequence, and air-dry to obtain the finished product.

Embodiment 3

[0026] Embodiment 3: The physical, mechanical and flame-retardant properties of the modified cable filler of the present invention are shown in Table 1 below:

[0027] Table 1:

[0028] performance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com