Heat-resistant spandex fiber and preparation method thereof

A spandex fiber, heat-resistant technology, applied in fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve problems such as heat resistance, limit the application of spandex, reduce elasticity, etc., and achieve excellent heat resistance and stable chemical structure , The effect of increasing the heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

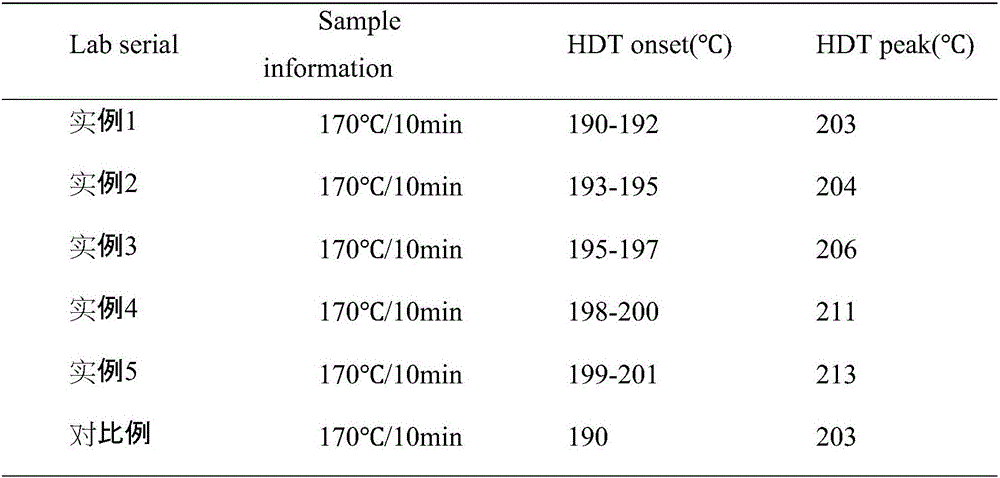

Examples

Embodiment 1

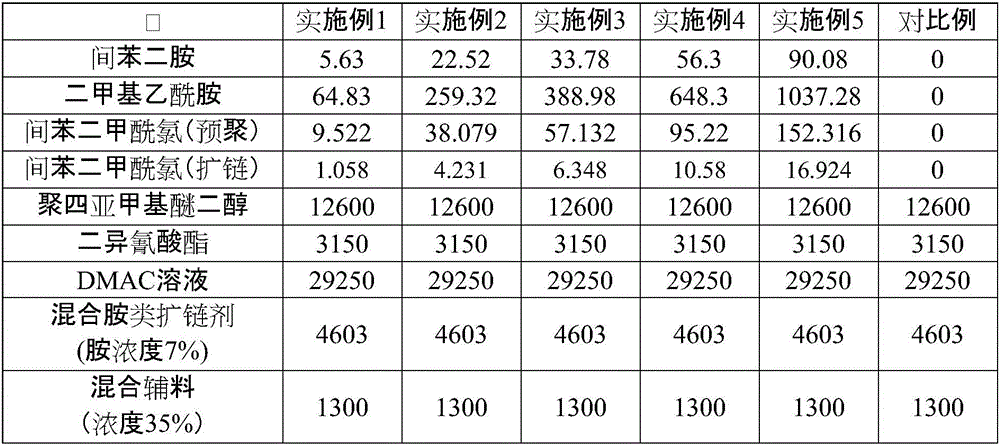

[0027] Embodiment 1: According to the data ratio in the scale table

[0028] Add m-phenylenediamine to dimethylacetamide at a concentration of 8%, lower the temperature to 0°C, and gradually add isophthaloyl chloride to react, and isophthaloyl chloride accounts for 90% of the total mass to obtain a prepolymer solution; add ammonia to the prepolymer solution to neutralize the hydrogen chloride therein to generate ammonium chloride solid insoluble in the solution; filter and remove the ammonium chloride to obtain a transparent prepolymer filtrate; then add the remaining spacer to the prepolymer filtrate Phthaloyl chloride, continue chain extension to obtain polymer solution; add neutralizing agent dibutylamine to the polymer solution, adjust the pH value of the polymer solution to neutrality, obtain the meta-aramid fiber spinning stock solution of the polymer The content is 20%.

[0029] React polytetramethylene ether glycol and diisocyanate at a molar ratio of 1:2 to obtain a ...

Embodiment 2

[0030] Embodiment 2: According to the ratio in the ratio table, the same method as described in Embodiment 1 is used to prepare novel heat-resistant spandex fibers, wherein the addition amount of the meta-aramid spinning stock solution is 2% of the solid content of the polyurethane polymer.

Embodiment 3

[0031] Embodiment 3: According to the ratio in the ratio table, the same method as described in Embodiment 3 is used to prepare novel heat-resistant spandex fibers, wherein the addition amount of the meta-aramid spinning stock solution is 3% of the solid content of the polyurethane polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com