Semiconductor ultraviolet detection sensor and preparation method thereof

A semiconductor and sensor technology, applied in the field of ultraviolet light detection, can solve the problems of zinc oxide nanowires exposed to the air for a long time, and achieve the effect of improving the photoresponse current value, good repeatability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

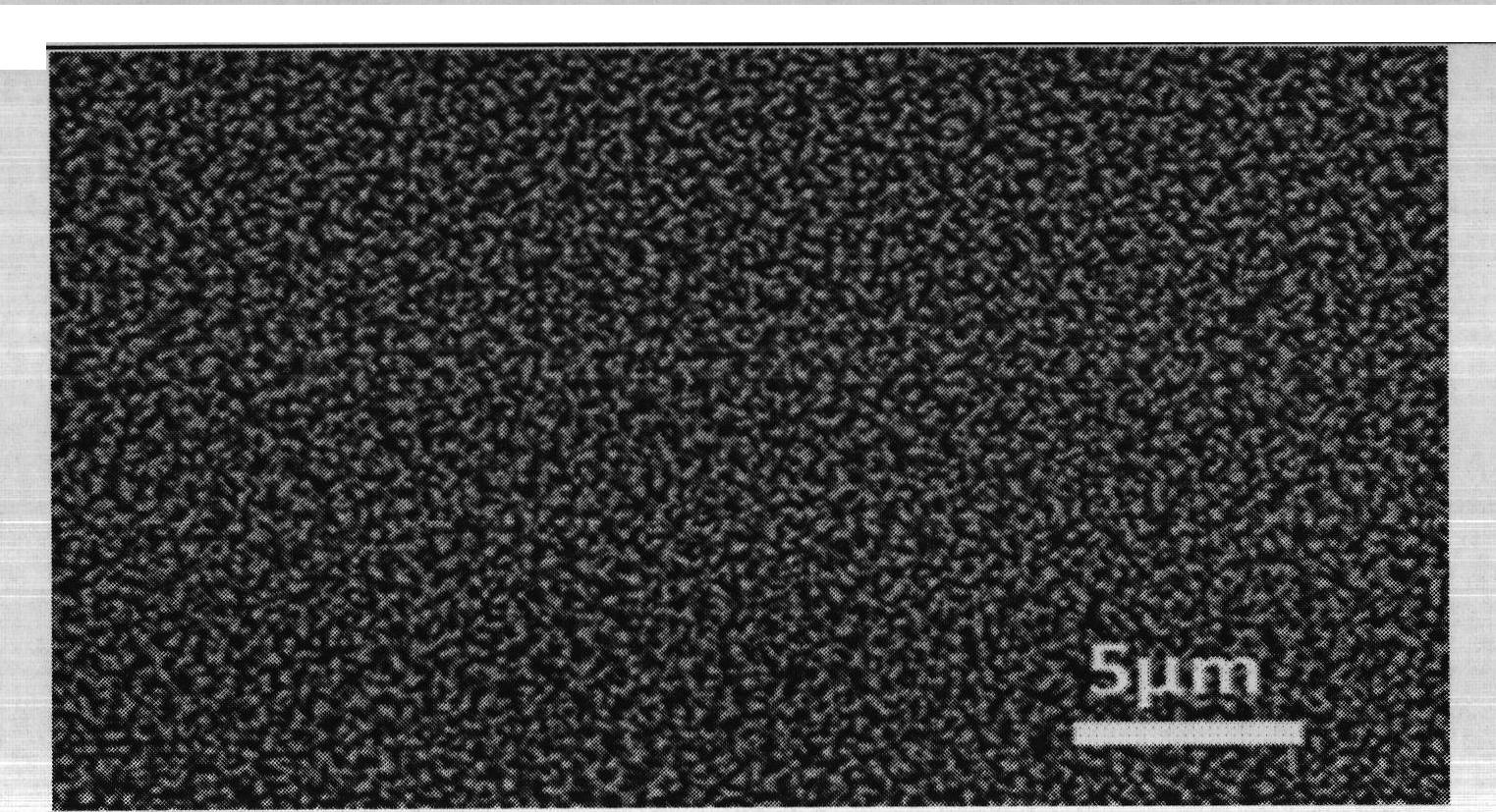

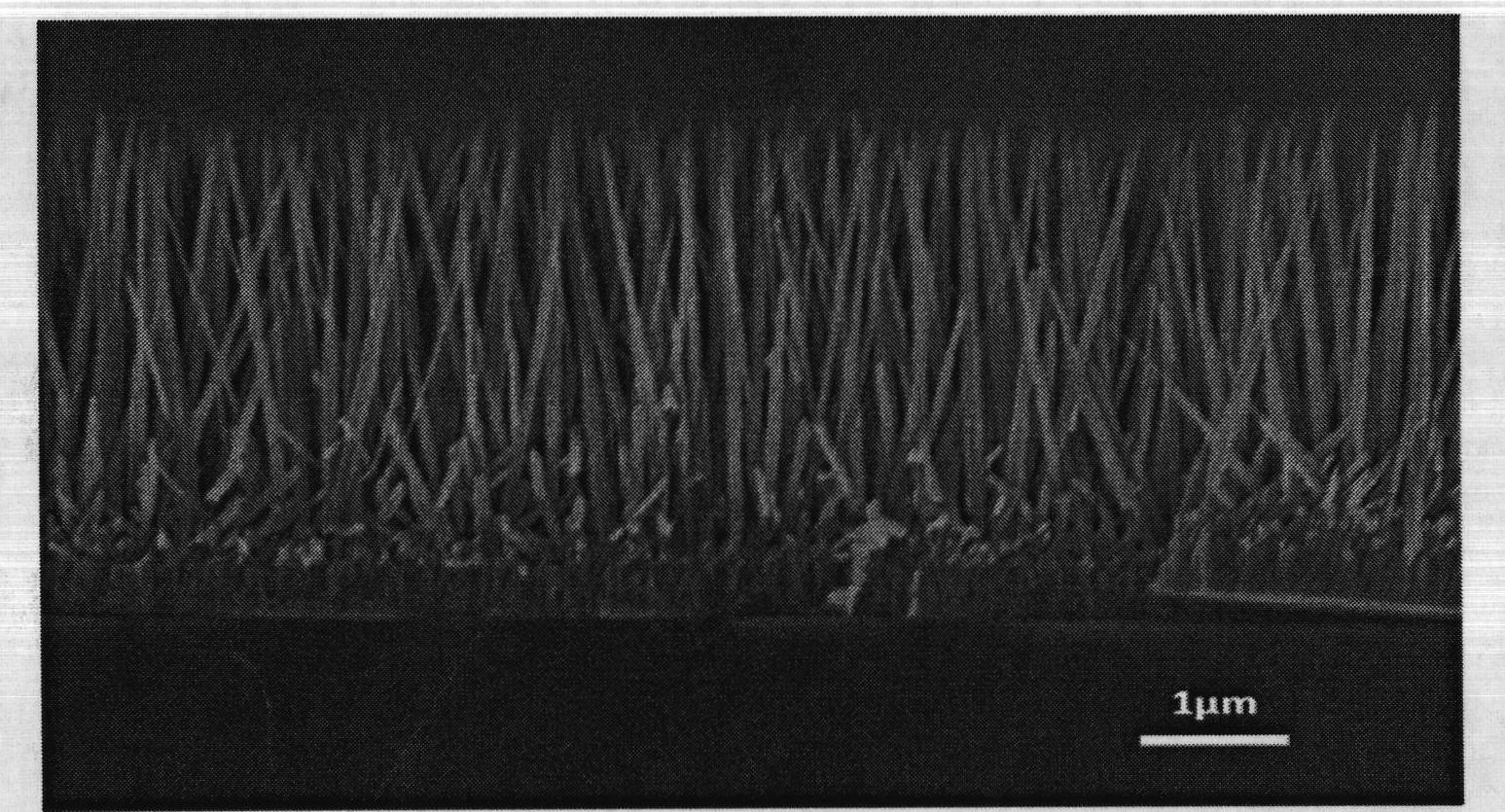

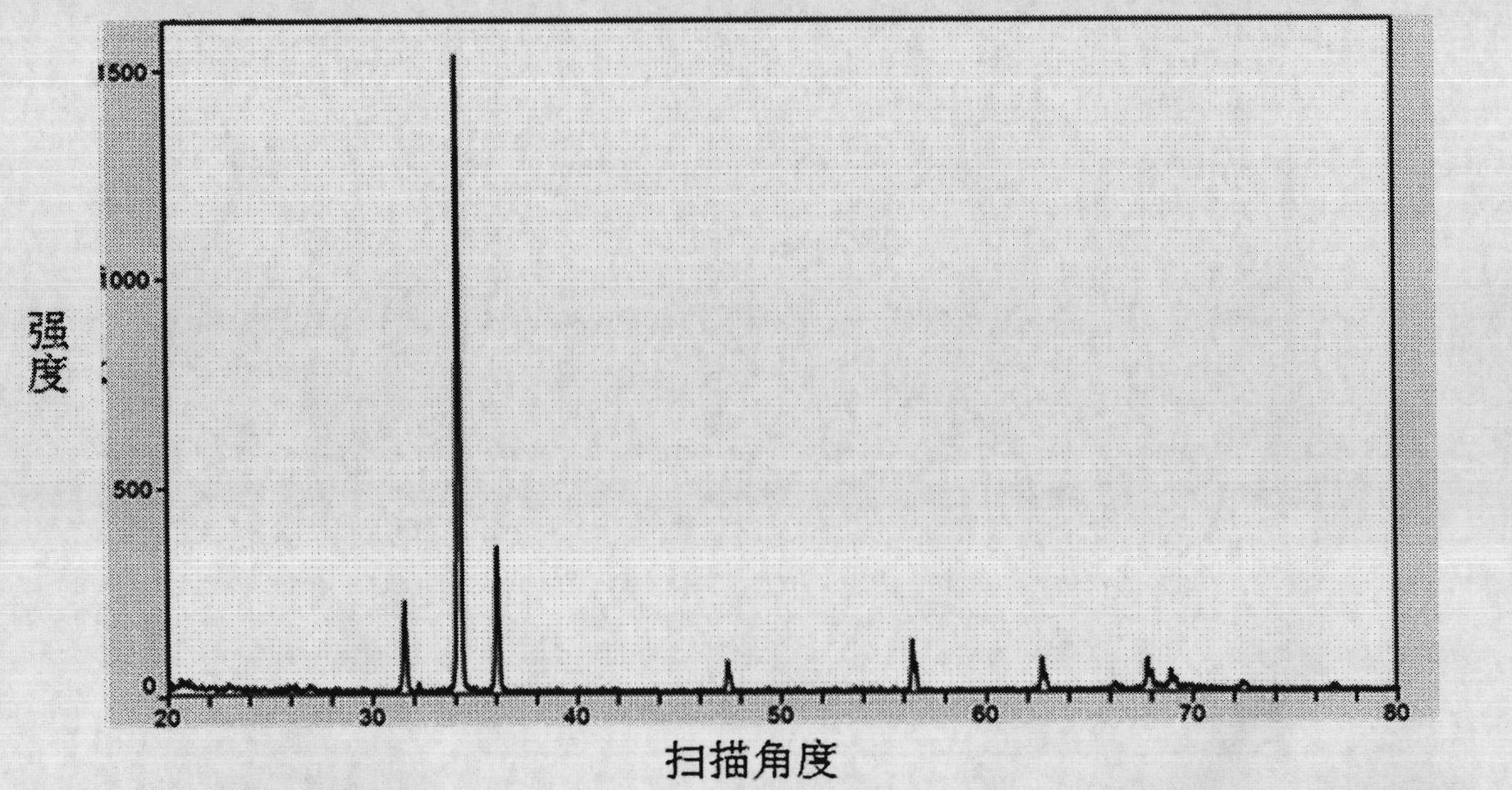

[0039] 1. At first adopt the high-temperature chemical vapor deposition method or hydrothermal method to grow the zinc oxide nanowire array perpendicular to the substrate on the substrate, the substrate used in the present invention is a silicon wafer, the zinc oxide nanowire array grown on the substrate For morphology and characterization, see the appendix figure 1 , attached figure 2 And attached image 3 .

[0040] When preparing by high temperature chemical vapor deposition, the mixture of ground 0.81g zinc oxide and 0.12g graphite powder is put into the reaction boat, and the reaction boat is put into the closed end of the single opening sleeve. Cut the silicon wafer whose polished surface is (100) crystal plane into small pieces of 0.5cm×0.8cm, ultrasonically clean them with HF, acetone, absolute ethanol and distilled water successively for 20 minutes, and blow dry the surface of the silicon wafer with nitrogen after taking it out. Bake in an oven at 175°C for 1 hour...

Embodiment 2

[0059] Example 2: Preparation of a high-response ultraviolet light sensor with non-hermetically sealed ohmic contacts

[0060] Spin-coat a layer of photoresist on the glass sheet, and the speed of the spinner is changed from slow to fast, and the final speed is 3000 rpm, and the speed is maintained for 60 seconds. Then pre-baked in an oven at 90 degrees Celsius for 40 minutes, then exposed the electrode pattern on the mask plate to the glass sheet under the microscope of the photolithography machine, and then baked it at 110 degrees Celsius for 30 minutes, and made an insertion with a width of 10 μm after development. Photolithographic pattern of half of the finger electrodes. Magnetron sputtering a layer of zinc oxide film with a thickness of about 300-4000nm, and then sputtering a layer of chromium barrier layer on the zinc oxide film (or not combined with Zn(NO 3 ) 2 Other metals that react with HMTA), the thickness is about 10-100nm. After stripping, a comb-tooth electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com