Flexible semi-clarity strain sensor and preparation method thereof

A strain sensor, flexible polymer technology, applied in the field of sensors, to achieve the effect of simple method, fast response sensitivity, and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

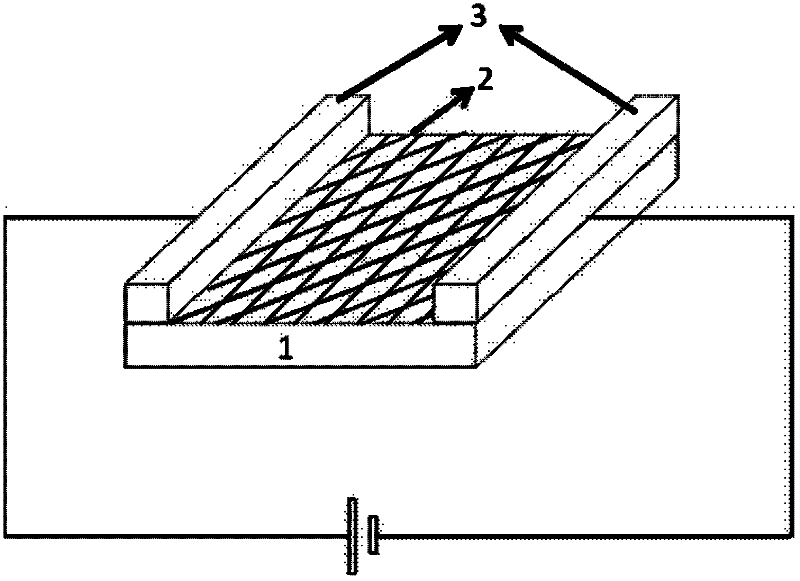

[0022] The steps of the preparation method provided by the invention are as follows:

[0023] 1. Dissolve the nanofibers in an organic solvent and stir until the solution is clear. The resulting solution was transferred to a needle for electrospinning on a substrate.

[0024] When the nanofiber is polystyrene (PS), the organic solvent is: dimethylformamide (DMF) and toluene, and each gram of PS particles needs 1-2mL DMF and 1-2mL toluene;

[0025] When the nanofiber is polyvinylpyrrolidone (PVP), the organic solvent is: ethanol, and every gram of PVP powder needs 8~12mL ethanol;

[0026] When the nanofiber is polyvinylidene fluoride (PVDF), the organic solvent is: dimethylformamide (DMF) solution and acetone, and each gram of PVDF powder needs 2-4mL DMF and 5-9mL acetone;

[0027] The production process of the substrate: mix PDMS and curing agent according to the ratio of 2:1 to 20:1 by volume, and place it in a constant temperature oven at 40-120°C for 0.5-2 hours to cure. ...

example 1

[0033] 1. Mix 10mL PDMS and 1mL curing agent, and place in a constant temperature oven at 60°C for 1 hour to cure. After curing, cut the PDMS into 1.5cm*0.5cm size for later use.

[0034] 2. Dissolve 0.7 g of PS particles in 3 mL of a mixed solution of dimethylformamide (DMF) and toluene (volume ratio 1:1), and stir for 3 hours until the solution is clear. The resulting solution was transferred to a needle tube and the PS was evenly spun onto the PDMS using a propulsion speed of 0.003 mm / s.

[0035] 3. Prepare 125mL of 0.03mol / L zinc acetate methanol solution and 65mL of 0.01mol / L potassium hydroxide methanol solution. The resulting solution needs to be stirred at 60°C; The solution was added dropwise and stirred for 2 hours; after the nanoparticle solution was prepared, the flexible polymer substrate was soaked in the solution so that the ZnO nanoparticles were attached to the nanofibers.

[0036] 4. Prepare 50 mL of 32 mol / L zinc nitrate aqueous solution and 50 mL of 32 mo...

example 2~10

[0045] Examples 2-10 According to the same process as Example 1, the strain sensor provided by the present invention can be prepared by using the process parameters and materials shown in the following table.

[0046]

[0047] *Concentration units in the table are mol / L.

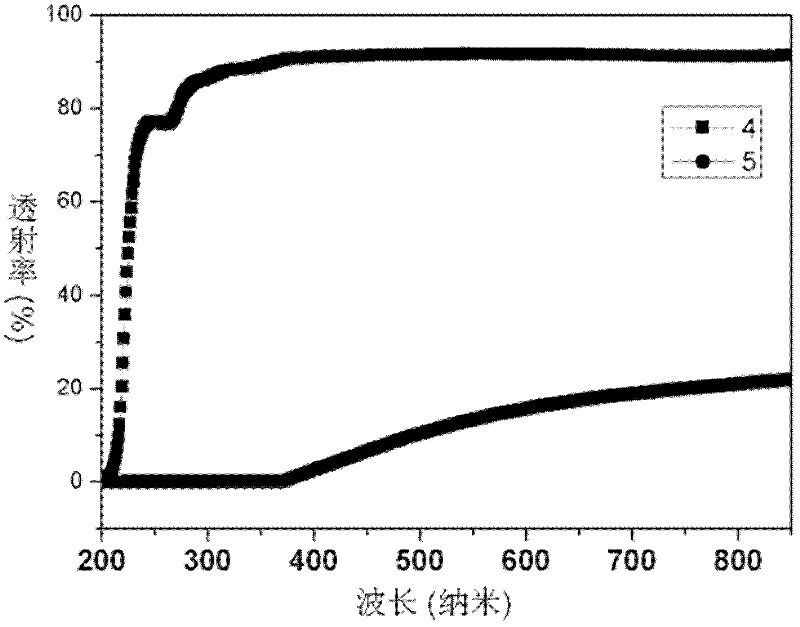

[0048] From the above analysis, it can be concluded that the present invention applies a flexible strain sensor prepared by synthesizing ZnO nanowire / nanofiber hybrid structure on a flexible polymer substrate, which has translucency, high durability, fast response and high sensitivity , can be used for precision mechanical detection, human motion monitoring and medical monitoring, and will have application prospects in future outdoor self-driving sensor systems. Any polymer that can be synthesized by electrospinning and any metal or metal oxide that can be grown by hydrothermal method can be used to fabricate flexible mechanical sensors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com