Synthesis method of zinc oxide nano wire harness array/foam graphene composite material and application thereof

A zinc oxide nanowire, foamed graphene technology, applied in the direction of zinc oxide/zinc hydroxide, graphene, nano carbon, etc., can solve the problems of high detection limit, low sensitivity, etc. The effect of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

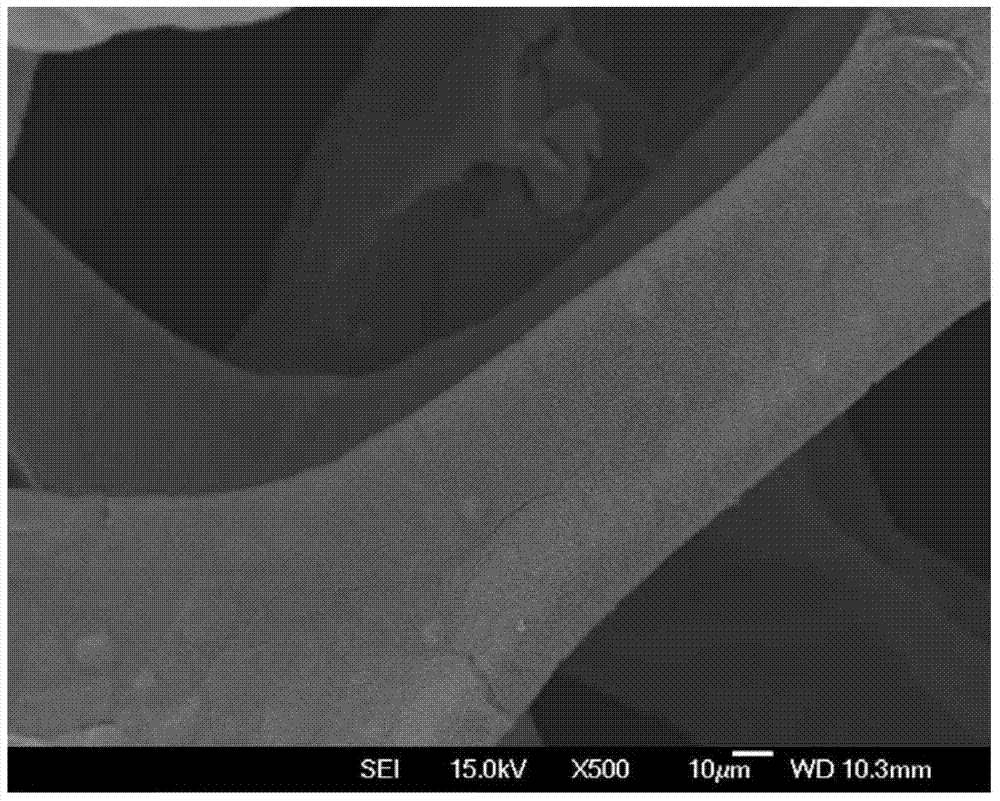

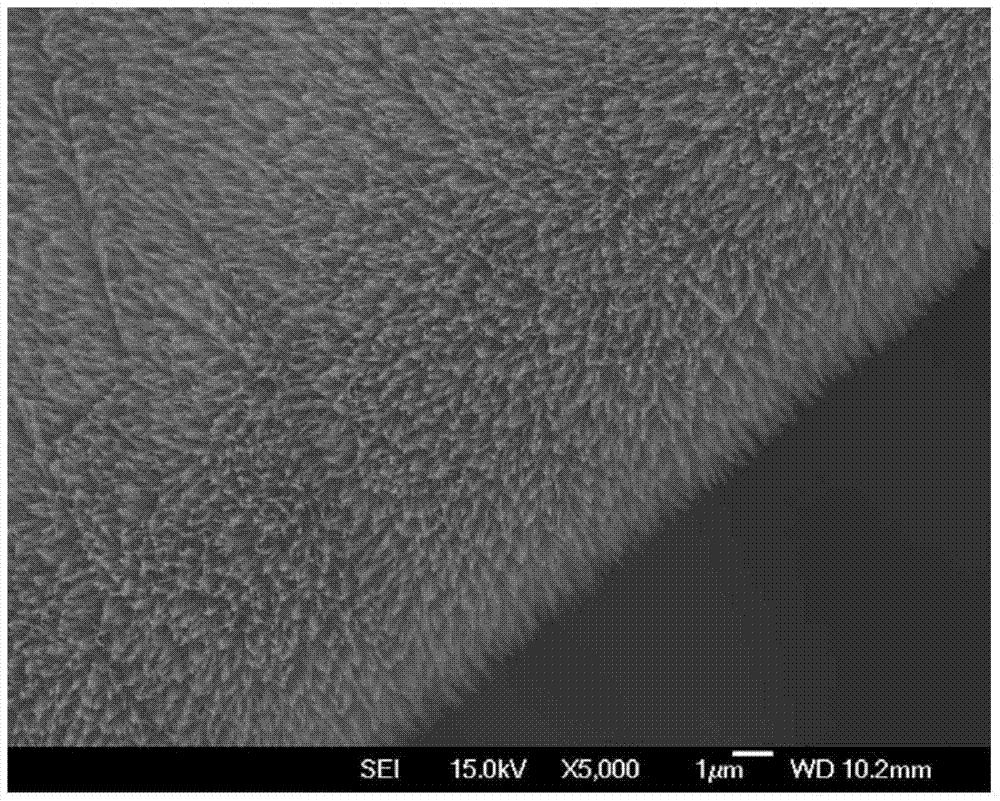

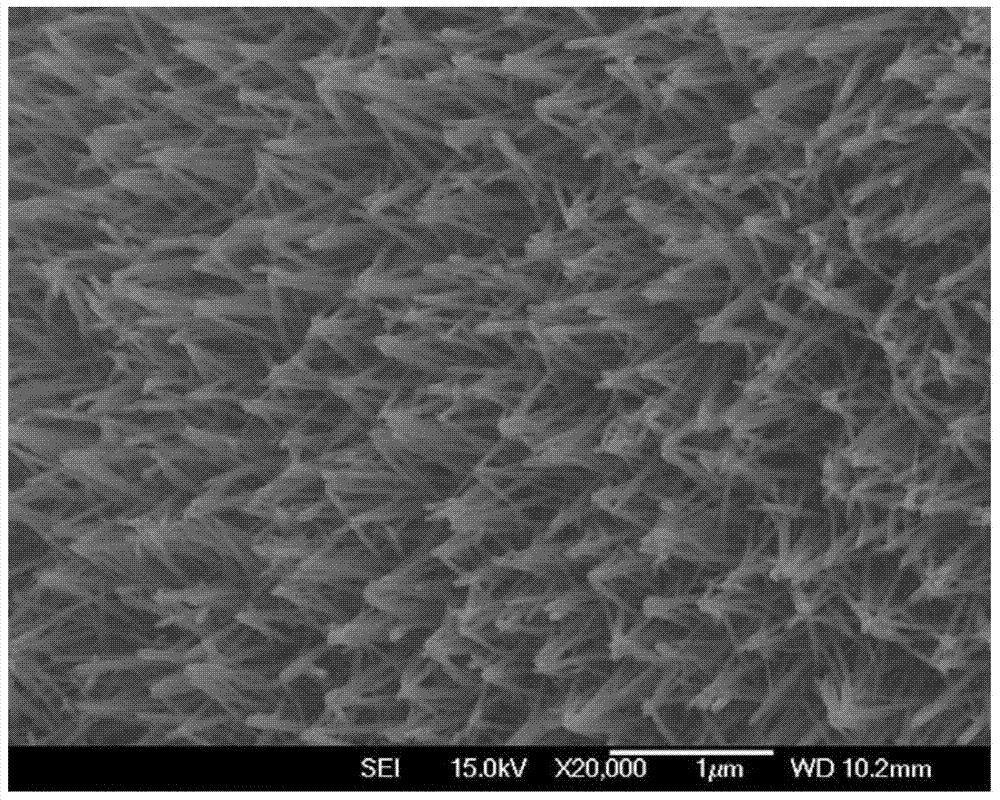

[0025] Specific embodiment one: the synthetic method of a kind of zinc oxide nanowire bundle array / foamed graphene composite material in the present embodiment is carried out according to the following steps:

[0026] 1. Chemical vapor deposition method:

[0027]1) Place nickel foam in the center of a quartz tube furnace, and heat it from room temperature at a rate of 20°C / min to 40°C / min under the protection of argon and hydrogen to a temperature of 1000°C to 1100°C. Keep warm for 30min~60min under the condition of 1000℃~1100℃, feed methane gas into the tube furnace at a rate of 5sccm~10sccm for 5min~20min under the condition of temperature 1000℃~1100℃, and then put the quartz tube furnace in 80°C / min-100°C / min cooling rate from 1000°C-1100°C to room temperature to obtain graphene-wrapped nickel foam; the density of the foam nickel described in step 1) is 420g / m 2 ~440g / m 2 , with a thickness of 1.6 mm to 2.0 mm; the flow rate of argon gas described in step 1) is 480 sccm t...

specific Embodiment approach 2

[0037] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1 1) the nickel foam is placed in the center of the quartz tube furnace, and it is heated from room temperature at 25°C / min to 35°C under the protection of argon and hydrogen. The heating rate of °C / min is heated to a temperature of 1000 °C to 1100 °C, and the temperature is kept at 1000 °C to 1100 °C for 40 min to 50 min, and the temperature is 1000 °C to 1100 °C. Methane gas is fed at a rate of 7sccm to 9sccm for 10min to 15min, and then the quartz tube furnace is cooled from a temperature of 1000℃ to 1100℃ to room temperature at a cooling rate of 85℃ / min to 95℃ / min to obtain graphene-wrapped Nickel foam; the density of nickel foam described in step 1) is 425g / m 2 ~435g / m 2 , with a thickness of 1.6 mm to 2.0 mm; the flow rate of argon gas in step 1) is 500 sccm, and the flow rate of hydrogen gas is 200 sccm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1 2), polymethyl methacrylate is dissolved in ethyl lactate, and the temperature is 90°C-110°C Heat and stir for 1h to 2h under the conditions to obtain a mixed solution. Use a sample gun to add the mixed solution dropwise to the graphene-wrapped nickel foam obtained in step 1) at an amount of 130 μL to 170 μL per square centimeter. Dry naturally, and then keep warm for 0.5h-1h at a temperature of 150°C-200°C to obtain foamed graphene coated with polymethyl methacrylate; the mixed solution described in step 1 2) methyl methacrylate The mass fraction of ester is 4% to 5%. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com