Antipollution self-cleaning GO/ZnO-PVDF film and preparation method thereof

A self-cleaning and anti-pollution technology, applied in the field of membrane separation, can solve the problems of porous membrane without self-cleaning ability, membrane without self-cleaning ability, film without self-cleaning ability, etc., to improve self-cleaning performance, good photocatalytic self-cleaning Ability, the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

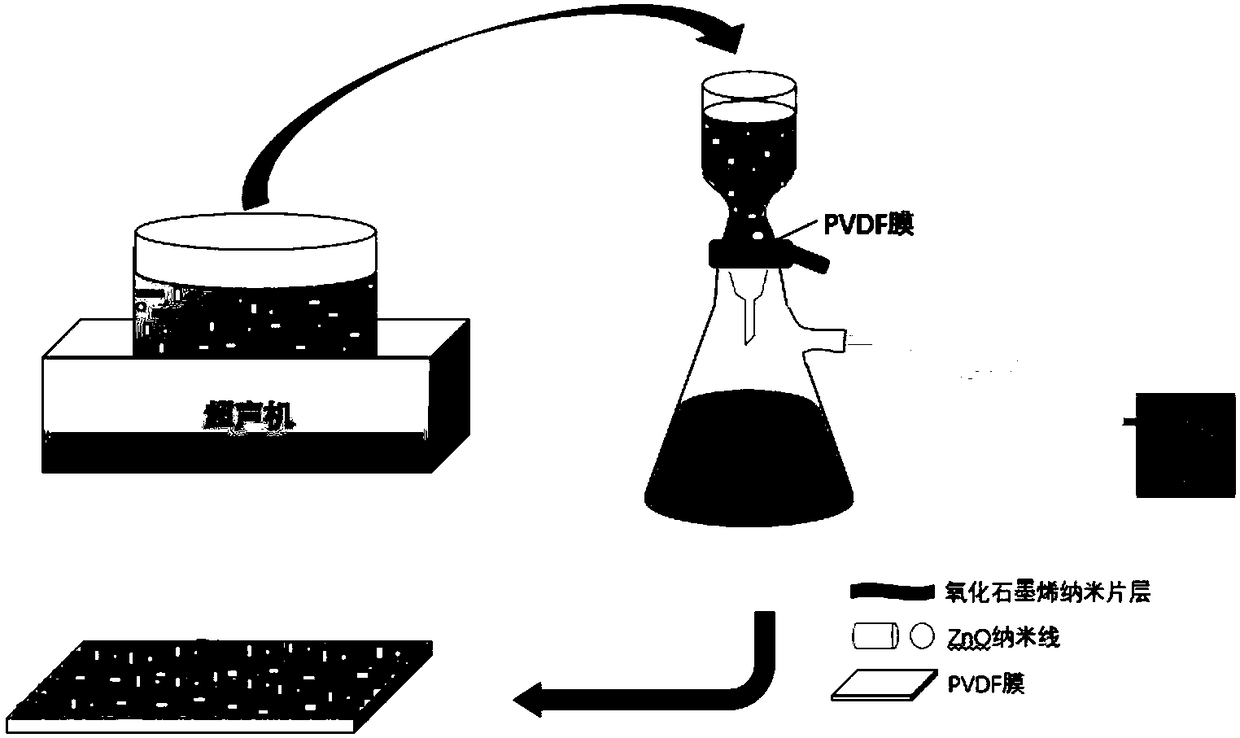

Embodiment 1

[0038] Both the GO solid powder and the ZnO nanowires were dried at 40° C. for 12 hours before use. The ZnO nanowires selected in this example had a diameter of 30-50 nm and a length of 200-400 nm. according to figure 1 In the schematic diagram of the process shown, 20 μg of GO nanosheet solid powder was added to 50 mL of deionized water, and treated in an ultrasonic machine for half an hour to form a uniform graphene oxide dispersion solution. Then, according to the ratio of GO:ZnO=1:6, the nanomaterials were respectively added to the graphene oxide dispersion, and then ultrasonically treated for half an hour, so that the nanomaterials were completely dispersed and evenly mixed with the GO nanosheets. Using a vacuum filtration device, the PVDF filter membrane with a membrane pore size of 0.05-0.07 μm and a hydrophilic angle of 83.2° is used as the base membrane layer, and the solution is suction-filtered on the membrane, and the filtered membrane is placed in a vacuum oven at...

Embodiment 2

[0044] Both the GO solid powder and the nano solid powder were dried at 40°C for 12 hours before use. The ZnO nanowires selected in this example had a diameter of 150-200 nm and a length of 800-1000 nm. Add 10 μg of GO nanosheet solid powder into 50 mL of deionized water, and process it in an ultrasonic machine for half an hour to form a uniform graphene oxide dispersion solution. Then, according to the ratio of GO:ZnO=1:15, the nanomaterials were respectively added to the graphene oxide dispersion, and then ultrasonically treated for half an hour, so that the nanomaterials were completely dispersed and evenly mixed with the GO nanosheets. Using a vacuum filtration device, the PVDF filter membrane with a membrane pore size of 0.12-0.15 μm and a hydrophilic angle of 43° is used as the base membrane layer, and the solution is suction-filtered on the membrane, and the filtered membrane is placed in a vacuum drying oven at 40°C 24h for subsequent analysis and testing. After testi...

Embodiment 3

[0046] Both the GO solid powder and the nano solid powder were dried at 40° C. for 12 hours before use. The ZnO nanowires selected in this example had a diameter of 10-20 nm and a length of 10-50 nm. Add 40 μg of GO nanosheet solid powder into 50 mL of deionized water, and process it in an ultrasonic machine for half an hour to form a uniform graphene oxide dispersion solution. Then, according to the ratio of GO:ZnO=1:3, the nanomaterials were respectively added to the graphene oxide dispersion, and then ultrasonically treated for half an hour, so that the nanomaterials were completely dispersed and evenly mixed with the GO nanosheets. Using a vacuum filtration device, the PVDF filter membrane with a membrane pore size of 0.43-0.5 μm and a hydrophilic angle of 61.5° is used as the base membrane layer, and the solution is suction-filtered on the membrane, and the filtered membrane is placed in a vacuum oven at 40°C 24h for subsequent analysis and testing. The GO / ZnO-PVDF film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com