Preparation method of tin mixed with zinc oxide nanowire

A technology of tin-doped zinc oxide and nanowires, which is applied in the field of gas-phase preparation of tin-doped zinc oxide one-dimensional nanomaterials, which can solve the problems of reducing synthesis temperature and product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

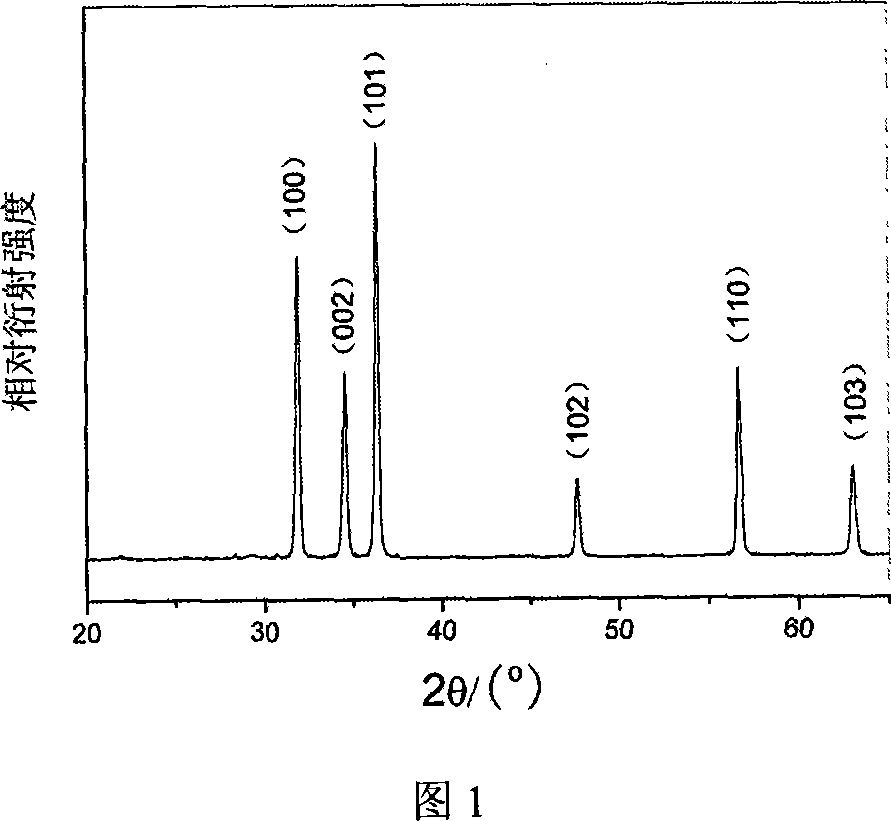

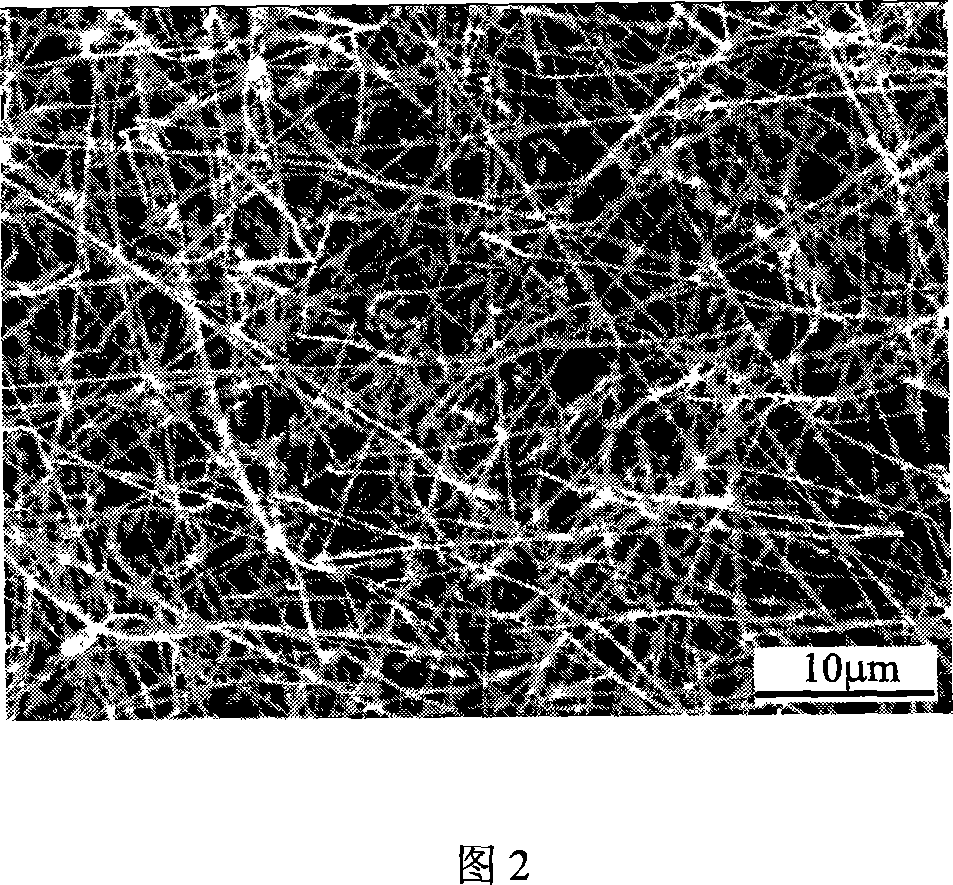

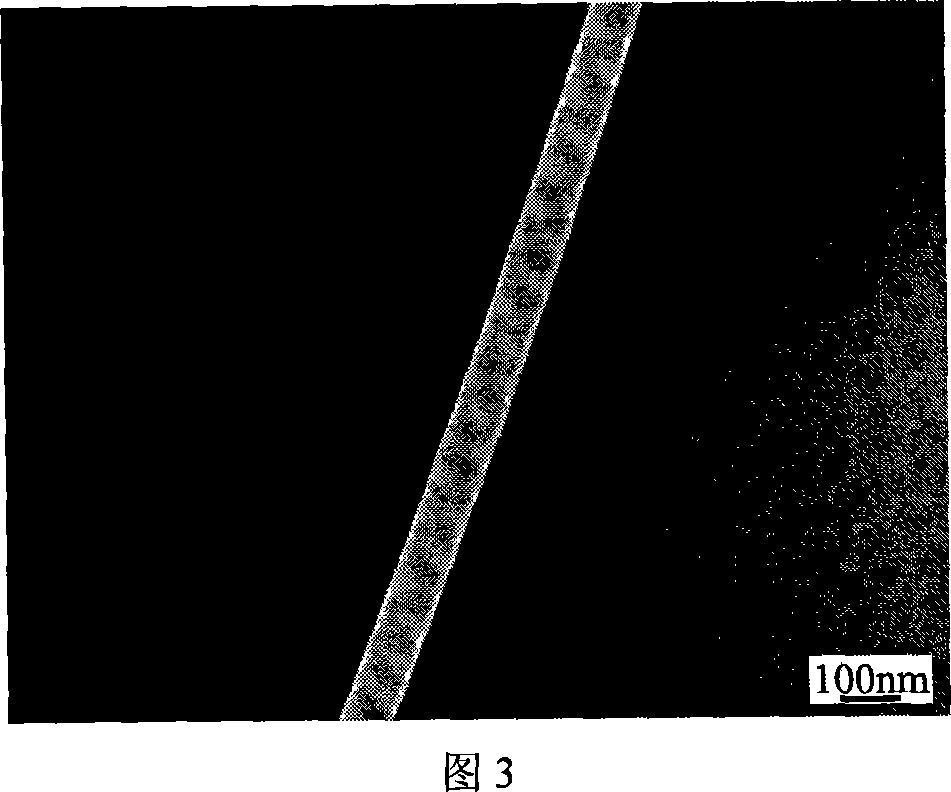

[0016] Example 1: First, the silicon (100) substrate was ultrasonically cleaned in acetone and absolute ethanol for 20 minutes, and then rinsed with deionized water. Mix ZnO powder, SnO and C powder according to the atomic ratio of 4:1:5, ball mill for 2 hours, mix thoroughly and evenly, put them in a porcelain boat as raw materials, and place a silicon substrate on it. Then the ceramic boat is placed in the middle of the quartz tube in the tube furnace, and the flowmeter is adjusted to feed argon (98%) / oxygen (2%) mixed gas (300 sccm) into the tube. In this atmosphere, the temperature of the tube furnace was raised to 900° C. at a rate of 20° C. per minute and kept for 40 minutes. The off-white fluff deposited on the substrate was tin-doped zinc oxide nanowires.

Embodiment 2

[0017] Embodiment 2: on the silicon (100) substrate that cleans up, adopt the Ag of magnetron sputtering method to deposit 20nm as catalyst, the silicon substrate coated with catalyst is as substrate; ZnO, SnO and C powder press 1: 1: 2 Mix well and put it in the porcelain boat as the evaporation source, place the silicon chip on the porcelain boat, then put the porcelain boat into the middle of the quartz tube in the tube furnace; adjust the flow meter to feed Ar and O into the tube 2 Mixed gas 300cm 3 min -1 , the proportion of oxygen is 1%, the reaction temperature is 930°C, and the temperature is kept at this temperature for 30 minutes, and the gas is continued until the tube furnace is cooled to room temperature, and the silicon substrate is taken out to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com