Preparation method of super-hydrophobic surface

A super-hydrophobic surface and hydrophobic substance technology, which is applied in the field of super-hydrophobic surface preparation, can solve the problems of poor bonding between primary structure photoresist and material body, super-hydrophobic surface structure damage, and super-hydrophobic surface failure. The effect of biocompatibility, good mechanical properties, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

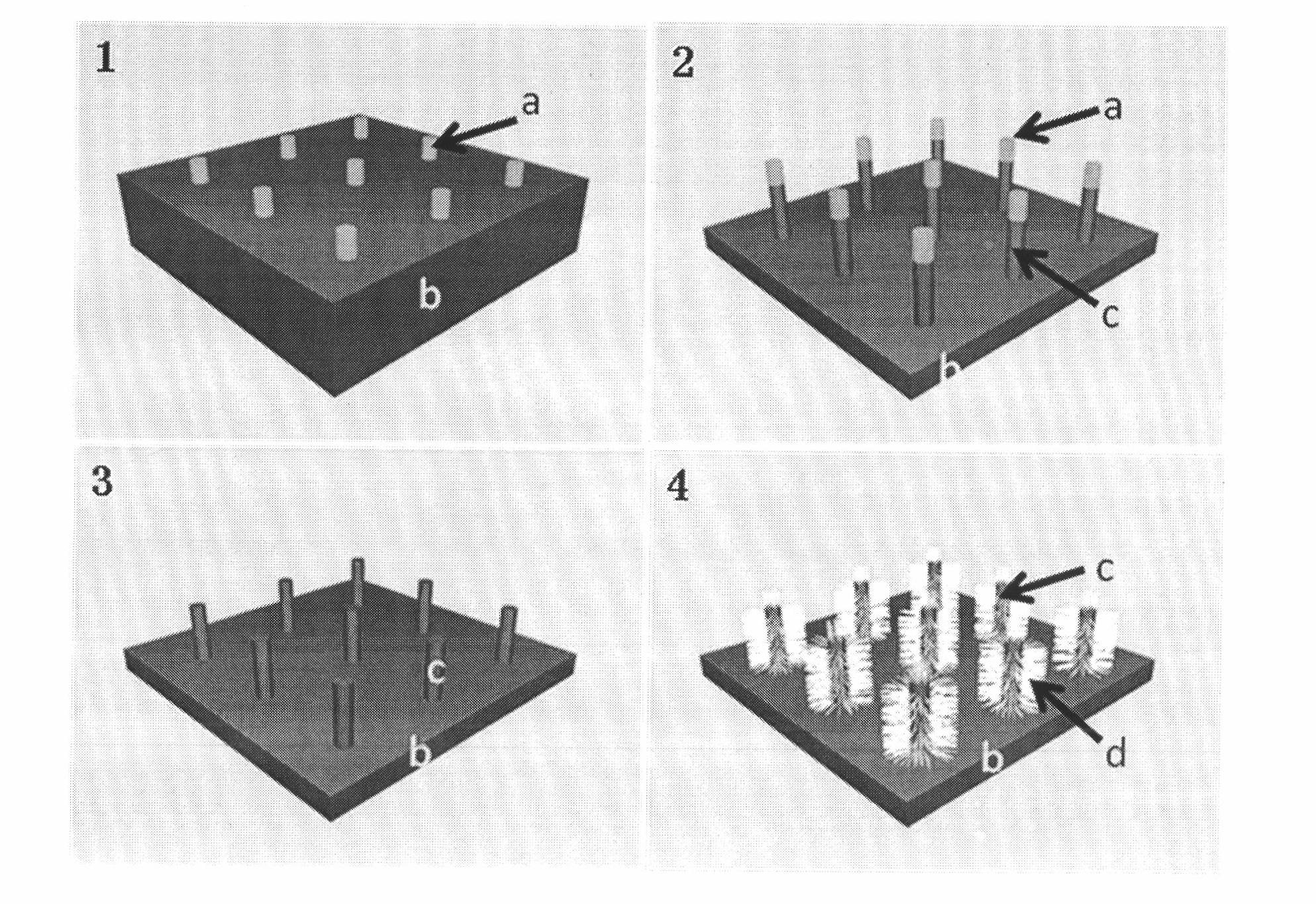

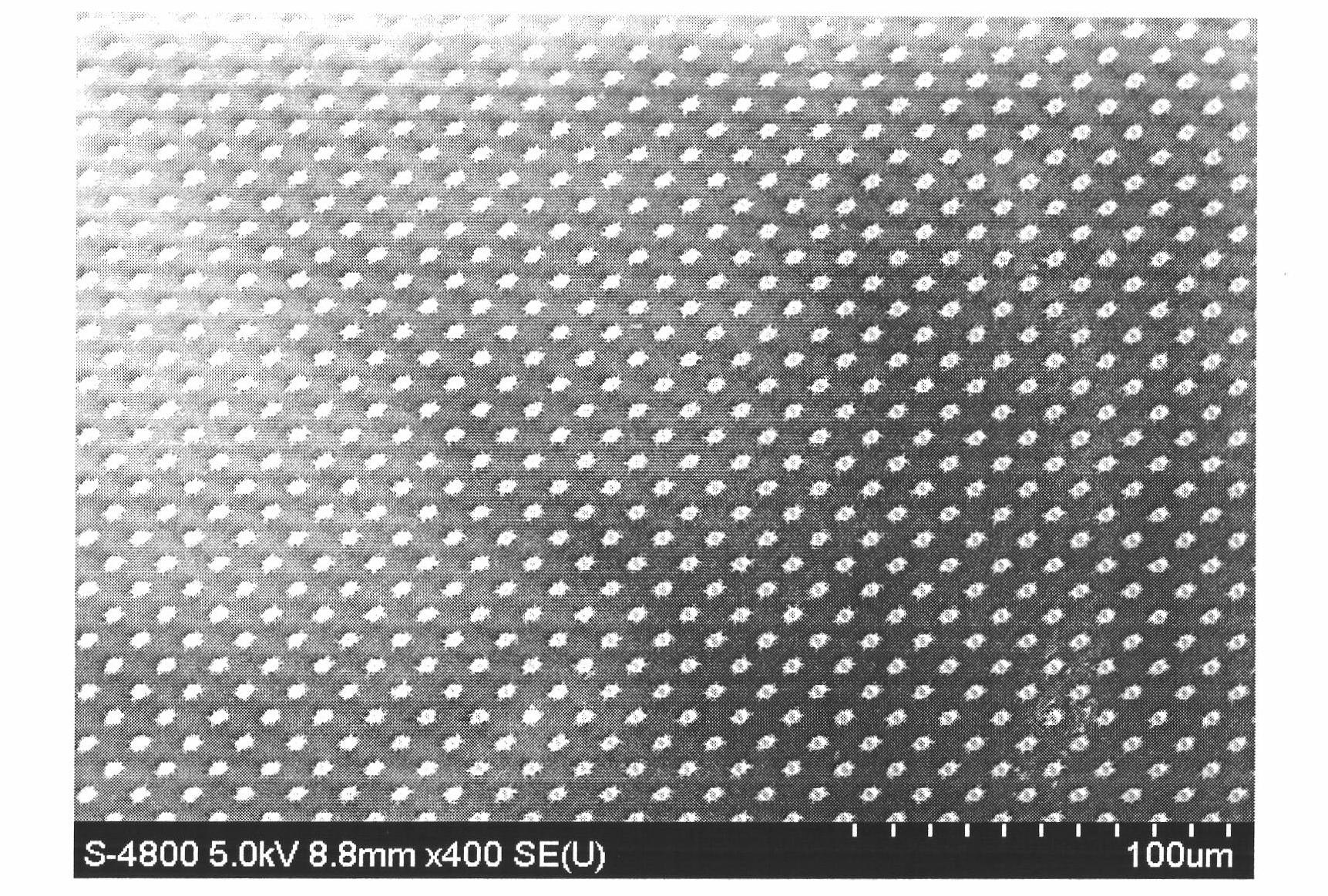

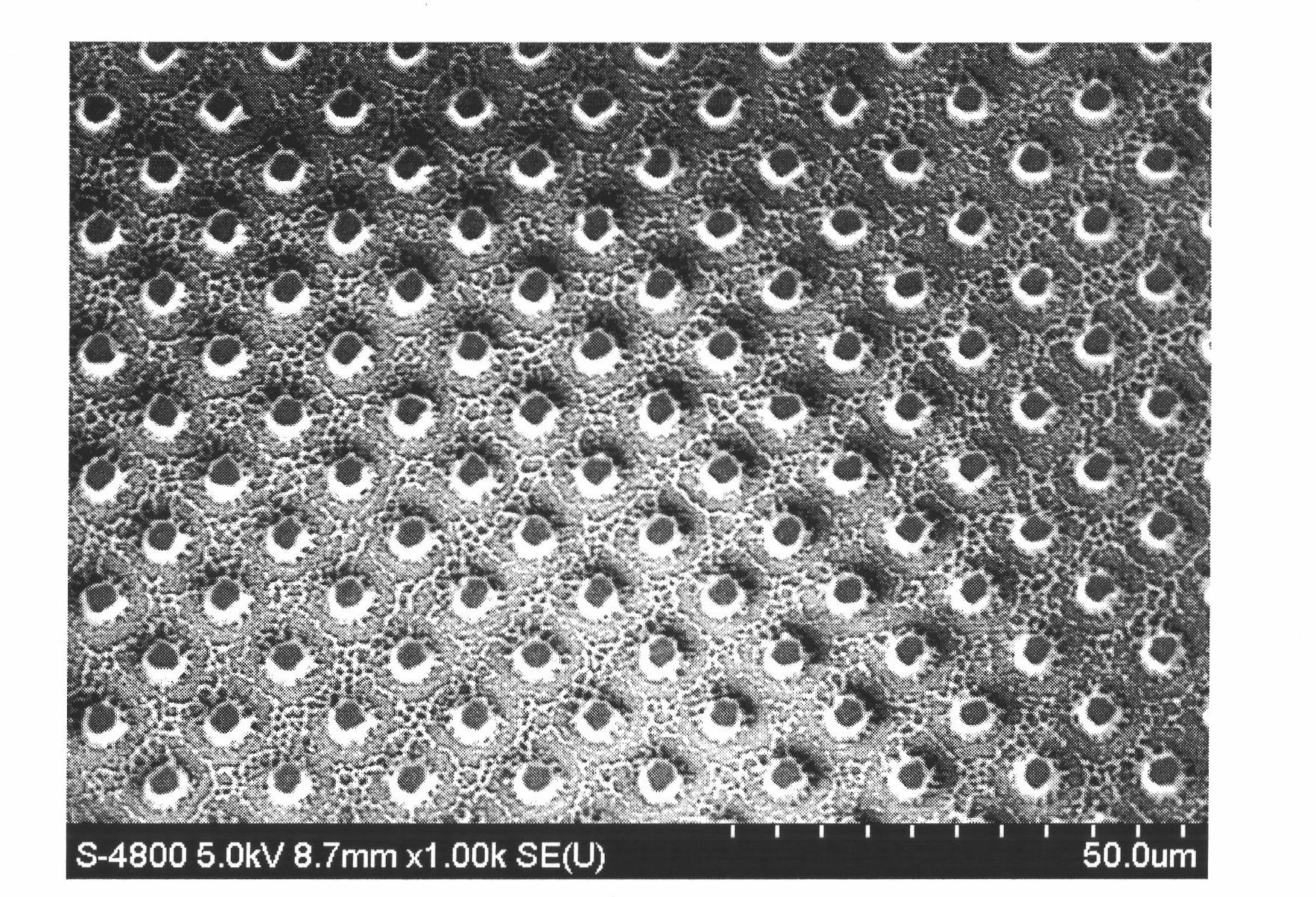

[0029] The polymer substrate used in the embodiments of the present invention is a polyethylene terephthalate film. The specific method is: first wash and dry the polyethylene terephthalate film, and then spin-coat a layer of photoresist (model DNR-L300) on it at a speed of 3000-5000 rpm. Pre-bake at 90°C for half an hour, expose, post-bake at 110°C for half an hour, and then develop to obtain a dotted array of photoresist. Then perform ion beam etching on it, the voltage is 1kV-10kV, the current is 0.01-1.5mA, and argon gas is passed through, and the vacuum degree is 1×10 -3 -1×10 -2Pa. A polymer columnar array with photoresist on the top is obtained. Then the photoresist is washed away with a solution to prepare a polymer columnar array. Then magnetron sputtering is used to sputter a zinc oxide seed layer on the surface of the polymer columnar array. Put it into the substrate into Zn(NO 3 ) 2 react in a mixed culture solution with hexamethylenetetramine at 60-100 degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com