Semiconductor sensor and production method

A sensor and semiconductor technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as long response and response time, cumbersome functional processes, and unfavorable large-scale applications, achieving low price, Effects of cost reduction, photoresponse and recovery time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

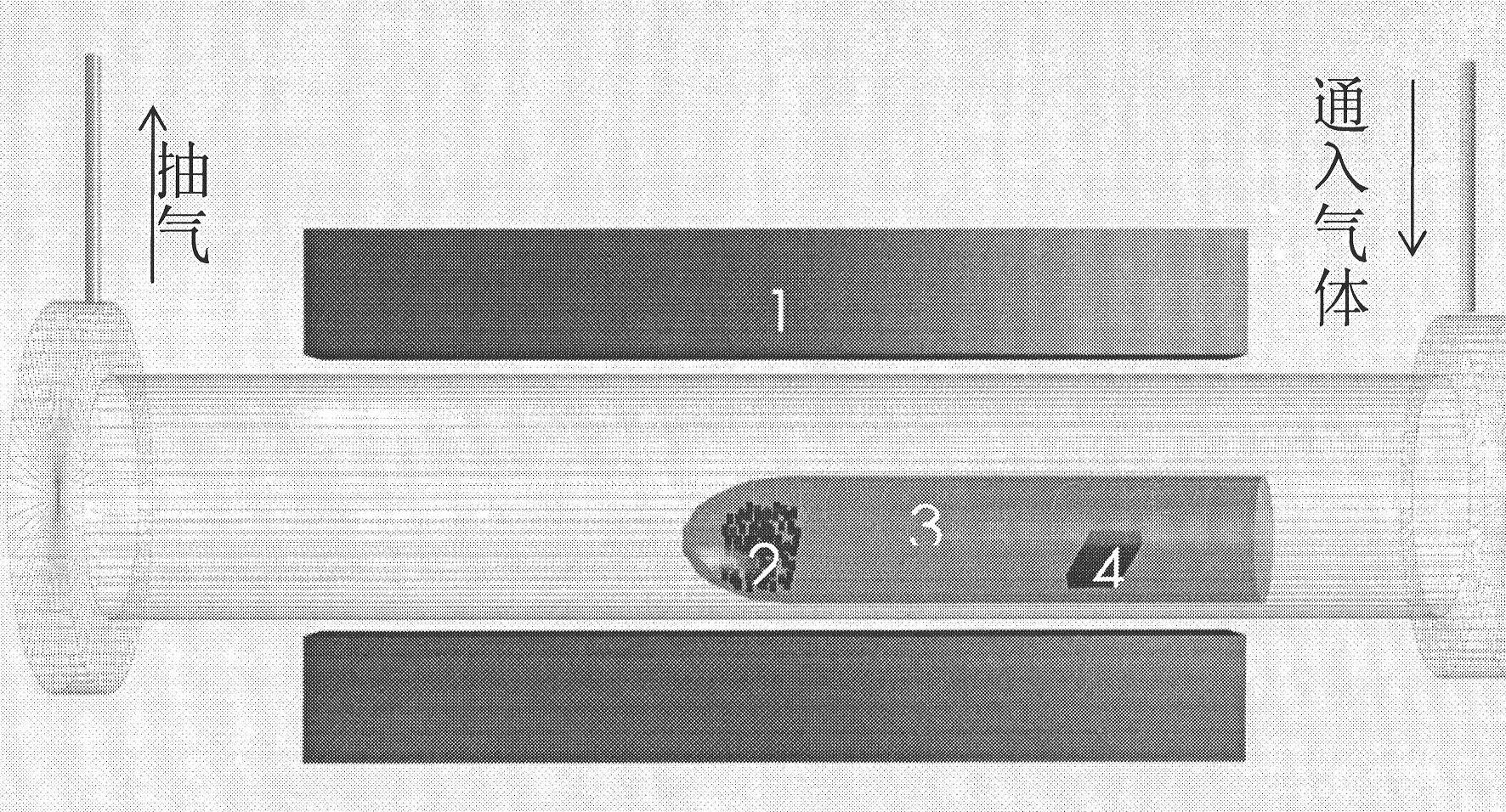

[0031] Embodiment 1: Detecting ultraviolet photons by using zinc oxide nanowire ultraviolet photon detectors with ohmic contacts of different integration levels.

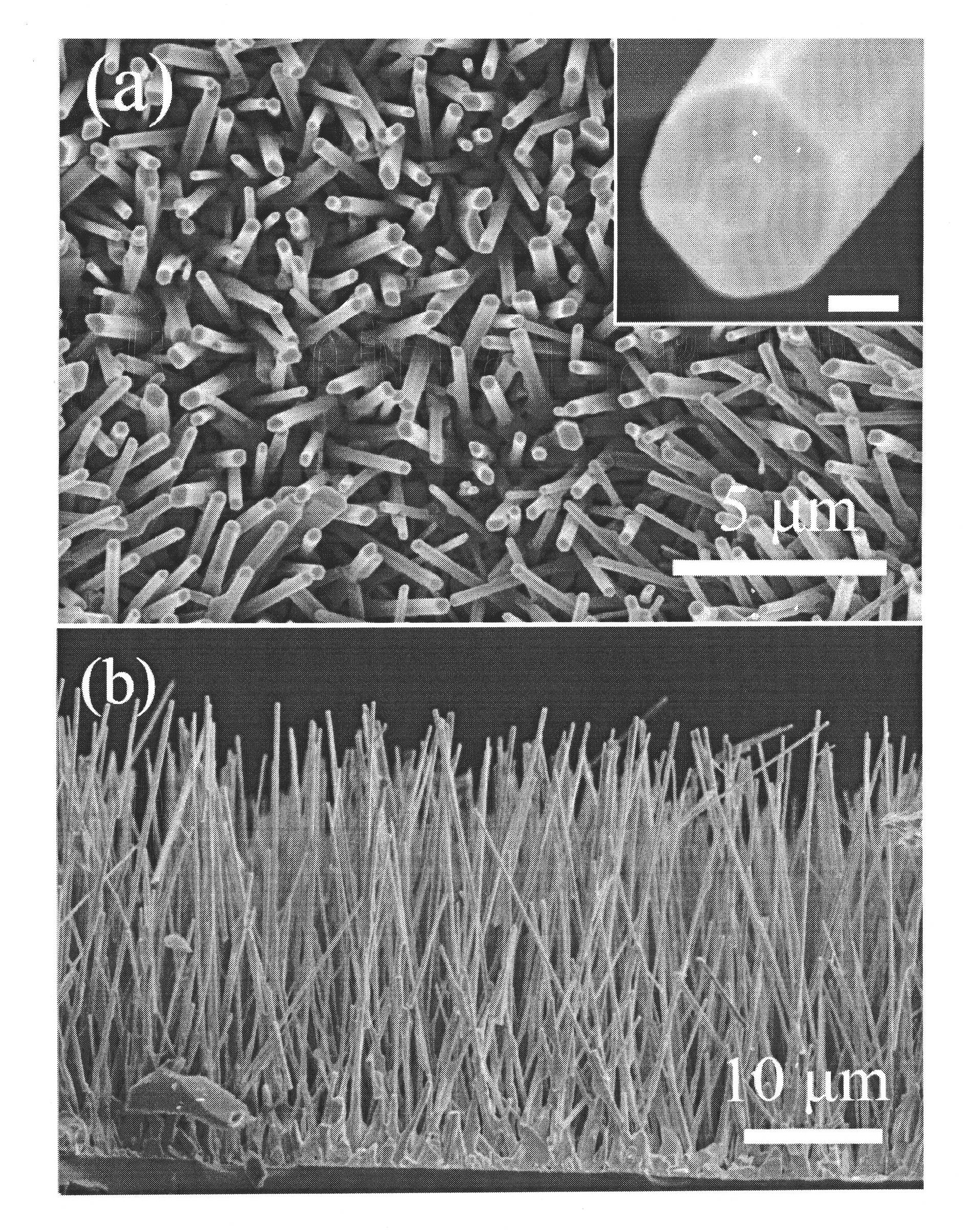

[0032] 1. Preparation of ZnO nanowire arrays using a vacuum tube furnace

[0033] The vacuum tube furnace used in the embodiment of the present invention is referring to appendix figure 1 , figure 1 Middle: 1 is a tube furnace, 2 is a mixture of zinc oxide and carbon placed in a casing, 3 is a quartz casing, and 4 is a silicon substrate. The outer diameter of the tube furnace used in the present invention is 60 centimeters, and the length is 100 cm, and the outer diameter of the single opening casing is 18 mm, and the length is 28 cm. The length of the constant temperature zone of the tube furnace is 20cm.

[0034] During preparation, put the ground mixture of 0.81g of zinc oxide and 0.12g of graphite powder into the reaction boat, and the reaction boat is put into the closed end of the single-open casing. Cut t...

Embodiment 2

[0043] Implementation Example 2: Using a zinc oxide nanowire ultraviolet photon detector with Schottky contacts of different integration levels to detect ultraviolet photons.

[0044] 1. The preparation method of the zinc oxide nanowire array is as in Example 1.

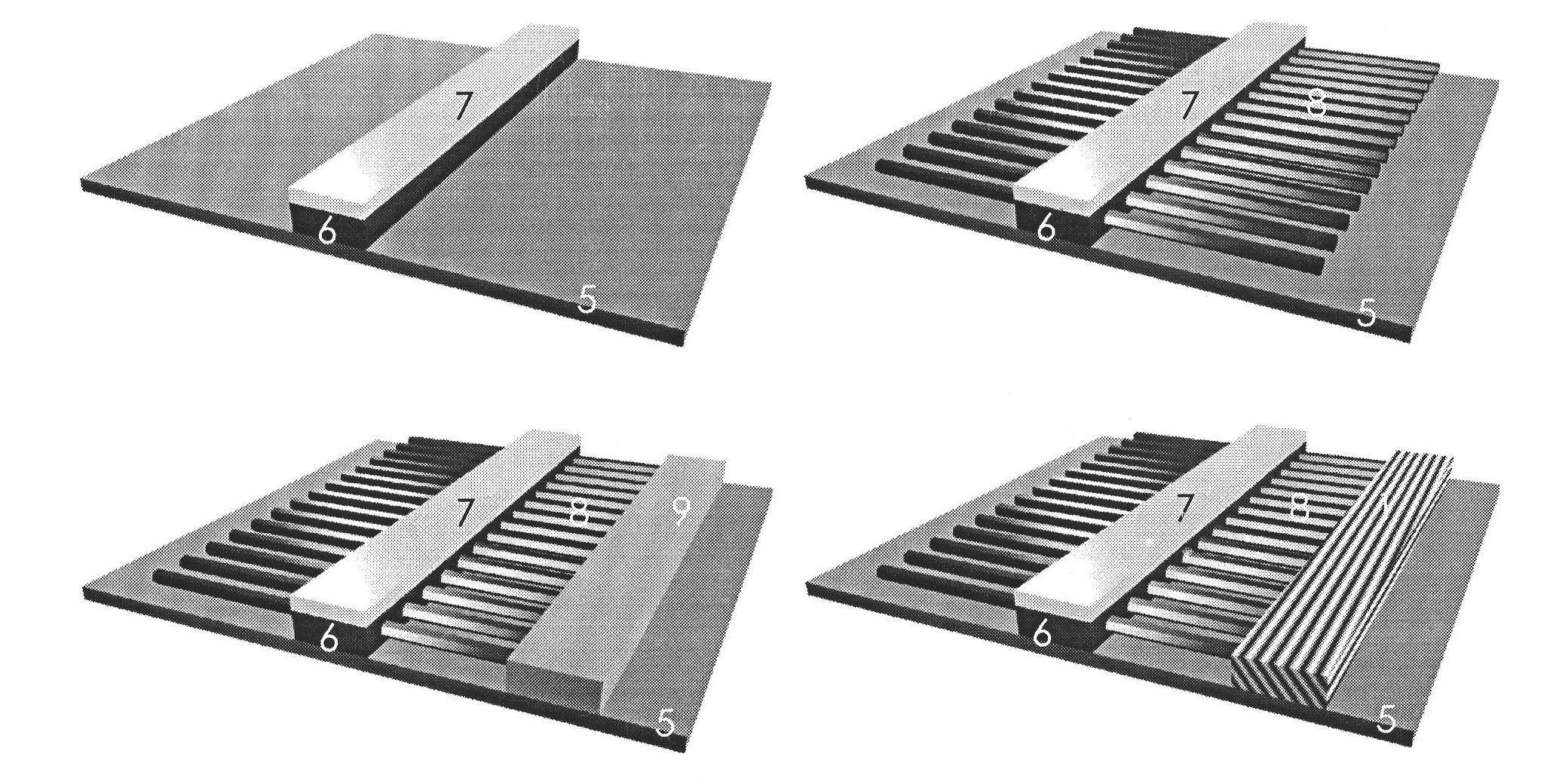

[0045] 2. Preparation of Schottky contact ZnO nanowire UV photon detector.

[0046] After cleaning and drying the other piece of glass, place the silicon wafer product facing the glass piece, and apply a certain amount of positive pressure to slide the silicon piece over the surface of the glass piece in the same direction. The nanowires on the glass sheet and almost parallel to each other are spin-coated with a layer of photoresist on the glass sheet. The rotation speed of the spinner is from slow to fast, and the final rotation speed is 3000 rpm, and the rotation speed is maintained for 60 seconds. Then pre-baked in an oven at 90 degrees Celsius for 40 minutes, and then under the microscope of the photolithography...

Embodiment 3

[0049] Implementation Example 3: Using a Schottky-contacted zinc oxide nanowire ultraviolet photon detector to detect ultraviolet photons of different intensities, different photon response curves are obtained from different photon intensities.

[0050] 1. The preparation method of the zinc oxide nanowire array is as in Example 1.

[0051] 2. Prepare a Schottky contact ultraviolet photon detector as in Example 2.

[0052] 3. Device testing

[0053] The intensity of ultraviolet photons irradiated on the detector is changed from 0.1μw / cm 2 to 3000μw / cm 2 Changes, the photoresponse current ranging from 0.2nA to 6μA and corresponding to the intensity is obtained. For specific tests, see the attached Figure 8 with 9 .

[0054] UV sensor composed of seven nanowires tested 22-3000μW / cm 2 The photoresponse current curves under different ultraviolet light intensities are shown in the appendix Figure 8 , starting from the curve closest to the abscissa, the measured UV photon inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com