ZnO nano-wire array synergistically modified by nano-Ag and TiO2 and preparation method of zinc oxide nano-wire array

A technology of zinc oxide nanowires and nanowire arrays is applied in the field of preparation of dye-sensitized and quantum dot-sensitized solar cell photoanode materials, which can solve the problems of easy shedding, complicated preparation process, low specific surface area, etc., and achieves improved conversion. Efficiency, simple preparation process, enhanced light absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

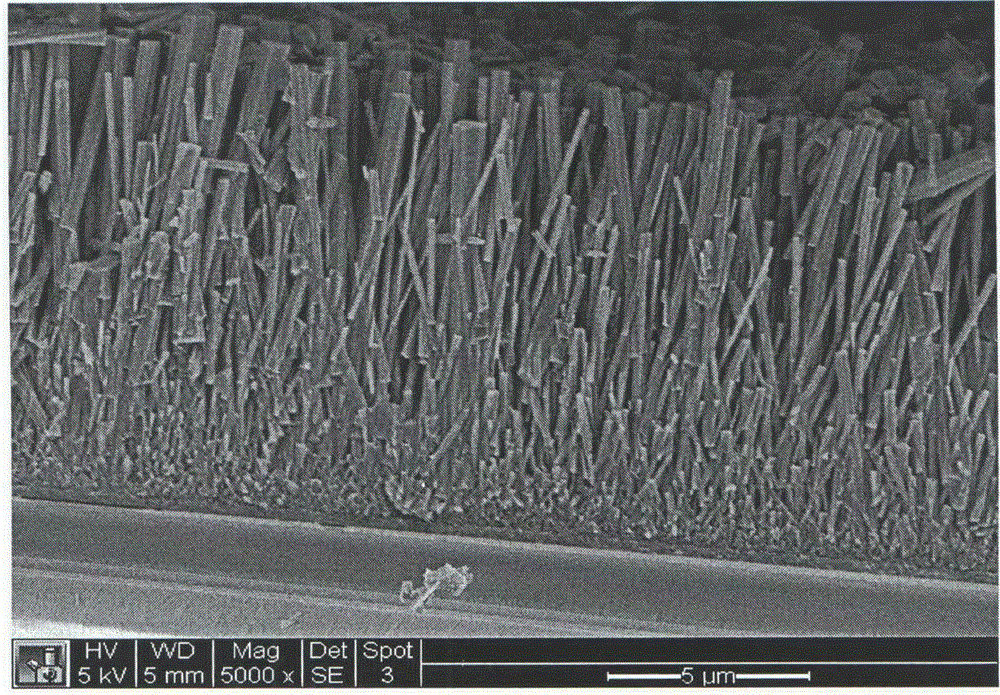

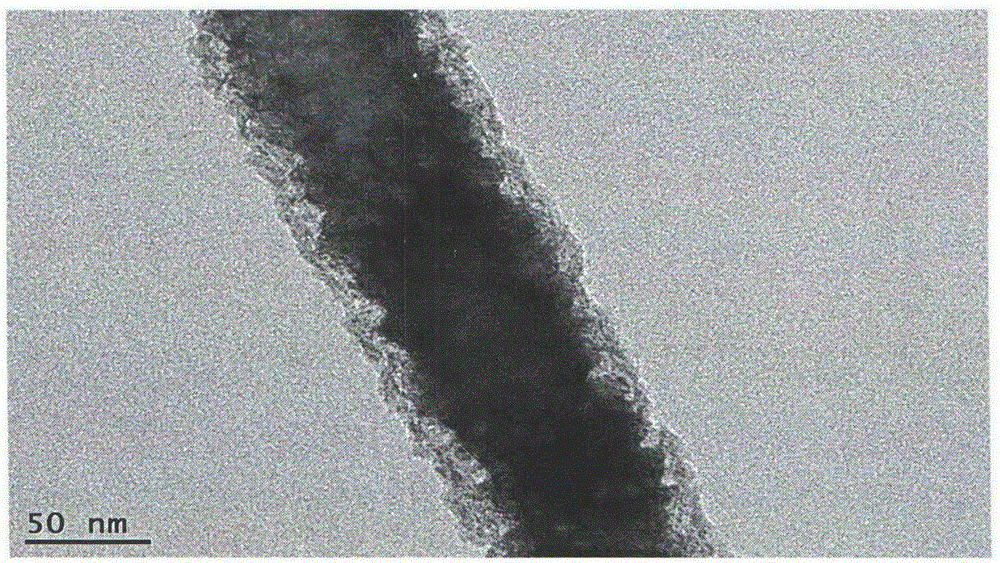

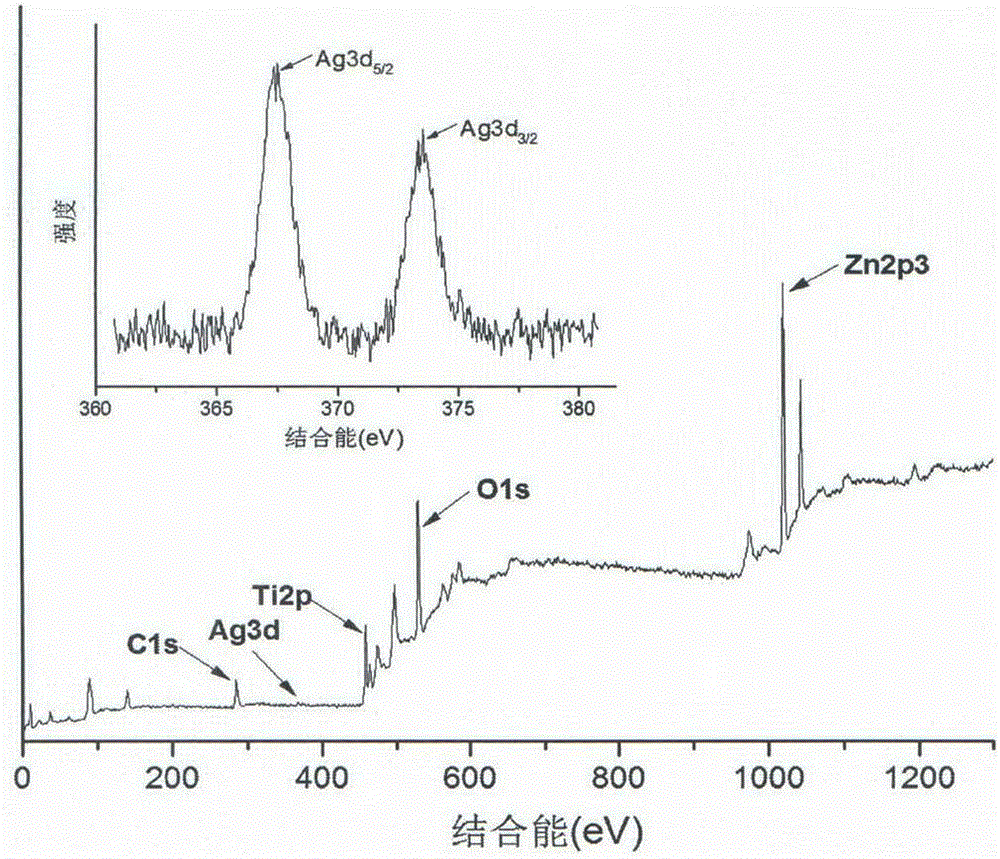

Image

Examples

Embodiment 1

[0020] a. Mix 2-methoxyethanol and ethanolamine at a volume ratio of 241:9, then add zinc nitrate dihydrate into the mixture, stir continuously for 2 hours in a water bath environment at a temperature of 60°C, and age to make a ZnO seed layer sol , wherein the mol ratio of zinc nitrate dihydrate and 2-methoxyethanol is 1:1;

[0021] b. Clean and dry the fluorine-doped tin oxide glass, spin-coat the sol obtained in step a on the surface of the fluorine-doped tin oxide glass by spin coating, set the parameters of the homogenizer: 3000rpm, 30s, spin at a temperature of 300 Bake at ℃ for 10 minutes, then raise the temperature in a muffle furnace at a rate of 5℃ / min, and anneal at a temperature of 400℃ for 10min to obtain a seed layer;

[0022] c. Dissolve zinc nitrate hexahydrate and hexamethylenetetramine in deionized water respectively, mix equal volumes to form a solution with a concentration of 0.2M; then fix the fluorine-doped tin oxide glass coated with the seed layer on the...

Embodiment 2

[0026] a. Mix 2-methoxyethanol and ethanolamine at a volume ratio of 241:9, then add zinc nitrate dihydrate into the mixture, stir continuously for 2 hours in a water bath environment at a temperature of 60°C, and age to make a ZnO seed layer sol , wherein the mol ratio of zinc nitrate dihydrate and 2-methoxyethanol is 1:1;

[0027]b. Clean and dry the fluorine-doped tin oxide glass, spin-coat the sol obtained in step a on the surface of the fluorine-doped tin oxide glass by spin coating, set the parameters of the homogenizer: 3000rpm, 30s, spin at a temperature of 300 Baking at ℃ for 10 minutes, then annealing at 400℃ for 10 minutes at a heating rate of 5℃ / min in a muffle furnace to obtain a seed layer;

[0028] c. Dissolve zinc nitrate hexahydrate and hexamethylenetetramine in deionized water respectively, mix equal volumes to form a solution with a concentration of 0.2M; then fix the fluorine-doped tin oxide glass coated with the seed layer on the mold and place Into the s...

Embodiment 3

[0032] a. Mix 2-methoxyethanol and ethanolamine at a volume ratio of 241:9, then add zinc nitrate dihydrate into the mixture, stir continuously for 2 hours in a water bath environment at a temperature of 60°C, and age to make a ZnO seed layer sol , wherein the mol ratio of zinc nitrate dihydrate and 2-methoxyethanol is 1:1;

[0033] b. Clean and dry the fluorine-doped tin oxide glass, and use the spin coating method to spin-coat the sol obtained in the step on the surface of the fluorine-doped tin oxide glass. The parameters of the homogenizer are set: 3000rpm, 30s, and the temperature is 300°C after spin coating. Bake at lower temperature for 10 minutes, then anneal at 400°C for 10 minutes at a heating rate of 5°C / min in a muffle furnace to obtain a seed layer;

[0034] c. Dissolve zinc nitrate hexahydrate and hexamethylenetetramine in deionized water respectively, mix equal volumes to form a solution with a concentration of 0.2M; then fix the fluorine-doped tin oxide glass c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com