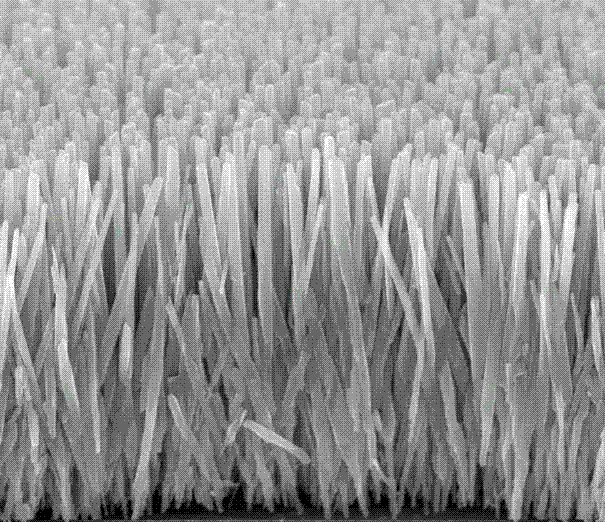

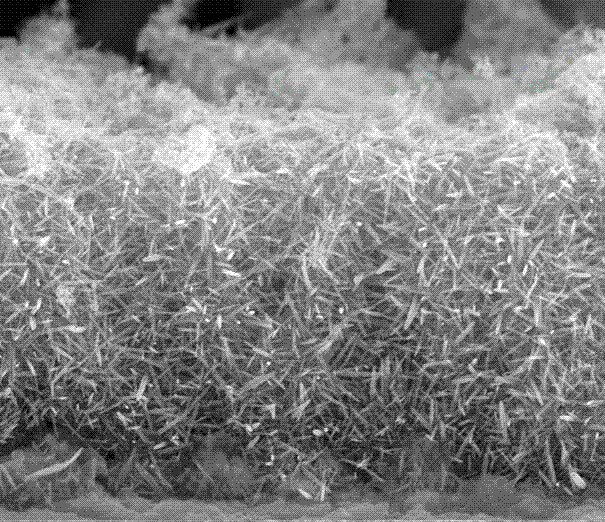

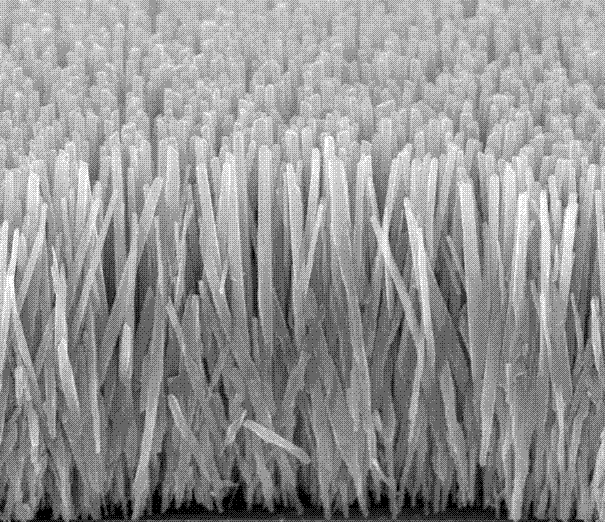

Preparation method of branched zinc oxide nanowire array film

A technology of zinc oxide nanowires and array films, which is applied in the field of nanomaterials, can solve the problems of low photoelectric conversion efficiency and small specific surface area, and achieve the effects of improving photoelectric conversion efficiency, increasing specific surface area, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: stainless steel wire mesh is cleaned with acetone, ethanol, deionized water, puts in autoclave, and reaction solution consists of: water (40ml); Zinc nitrate (0.05mol / L); Polyethyleneimine (0.003mol / L), hexamethylenetetramine (0.05mol / L), ammonia water (0.40mol / L). Heated to 90°C, reacted for 6 hours, cooled naturally to room temperature, took out the conductive substrate, and placed it in another autoclave for vulcanization treatment. The composition of the reaction solution was: water (20ml); thiourea (0.05mol / L). Heating to 120°C, reacting for 1 hour, naturally cooling to room temperature, taking out the conductive substrate, and heating and calcining the vulcanized conductive substrate at 200°C for 5 hours; after calcining, put it into the autoclave again, and the reaction solution consists of water (40ml); Zinc acetate (0.025mol / L); polyethyleneimine (0.008mol / L), hexamethylenetetramine (0.025mol / L), ammonia water (0.4mol / L). Heating to 90° C., reac...

Embodiment 2

[0014] Embodiment 2: plated indium tin oxide transparent conductive film glass with acetone, ethanol, deionized water cleans, puts in the autoclave, and reaction solution consists of: water (80ml); Zinc chloride (0.1mol / L); Ethyleneimine (0.005mol / L), hexamethylenetetramine (0.1mol / L), ammonia water (1.0mol / L). Heated to 120°C, reacted for 3 hours, cooled naturally to room temperature, took out the conductive substrate, and put it into another autoclave. The reaction solution consisted of: water (40ml); Na 2 S (0.05mol / L). Heating to 90°C, reacting for 3 hours, naturally cooling to room temperature, taking out the conductive substrate, and heating and calcining the vulcanized conductive substrate at 400°C for 4 hours; after calcining, put it into the autoclave again, and the composition of the reaction solution is: water (40ml); Zinc nitrate (0.025mol / L); polyethyleneimine (0.01mol / L), hexamethylenetetramine (0.025mol / L), ammonia water (0.40mol / L). Heating to 88° C., reactin...

Embodiment 3

[0015] Embodiment 3: Plating indium tin oxide transparent conductive film glass is cleaned with acetone, ethanol, deionized water, puts in the autoclave, and reaction solution consists of: water (1000ml); Zinc nitrate (0.02mol / L); Polyethylene Imine (0.003mol / L), hexamethylenetetramine (0.1mol / L), ammonia water (4.0mol / L). Heated to 100°C, reacted for 12 hours, cooled naturally to room temperature, took out the conductive substrate, and placed it in another autoclave. The composition of the reaction solution was: water (20ml); thioacetamide (0.02mol / L). Heating to 120°C, reacting for 2 hours, naturally cooling to room temperature, taking out the conductive substrate, heating and calcining the vulcanized conductive substrate at 500°C for 2 hours; after calcining, put it into the autoclave again, and the composition of the reaction solution is: water (100ml); Zinc sulfate (0.025mol / L); polyethyleneimine (0.005mol / L), hexamethylenetetramine (0.025mol / L), ammonia water (0.20mol / L)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com