ZnO nanowire biosensor and preparation method thereof

A biosensor and nanowire technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems affecting direct electron transfer of enzymes, uneven enzyme membranes, and reduced sensitivity, and achieve easy operation, improved detection sensitivity and accuracy, good orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Make a conductive layer on the substrate

[0021] An ITO layer is grown on a glass substrate to obtain an ITO glass substrate.

[0022] 2. Growth of ZnO nanowires on the conductive layer

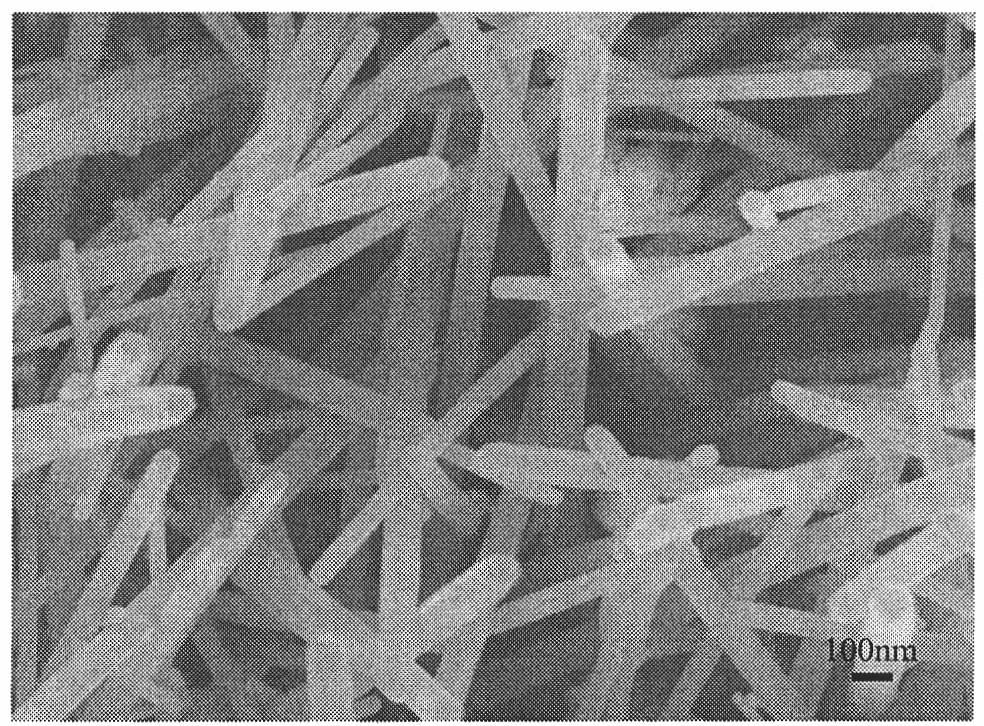

[0023] Use hydrothermal method to grow ZnO nanowires according to the following process conditions: use 0.01M zinc acetate and 0.01M hexamethylenetetramine to prepare a reaction solution, the growth temperature is 90°C, the growth time is 6h, and after the growth is completed, take it out at 60°C The grown ZnO nanowires have a nanoscale and ideal aspect ratio, and the morphology tends to be consistent, densely and uniformly clustered on the conductive layer, see figure 1 shown.

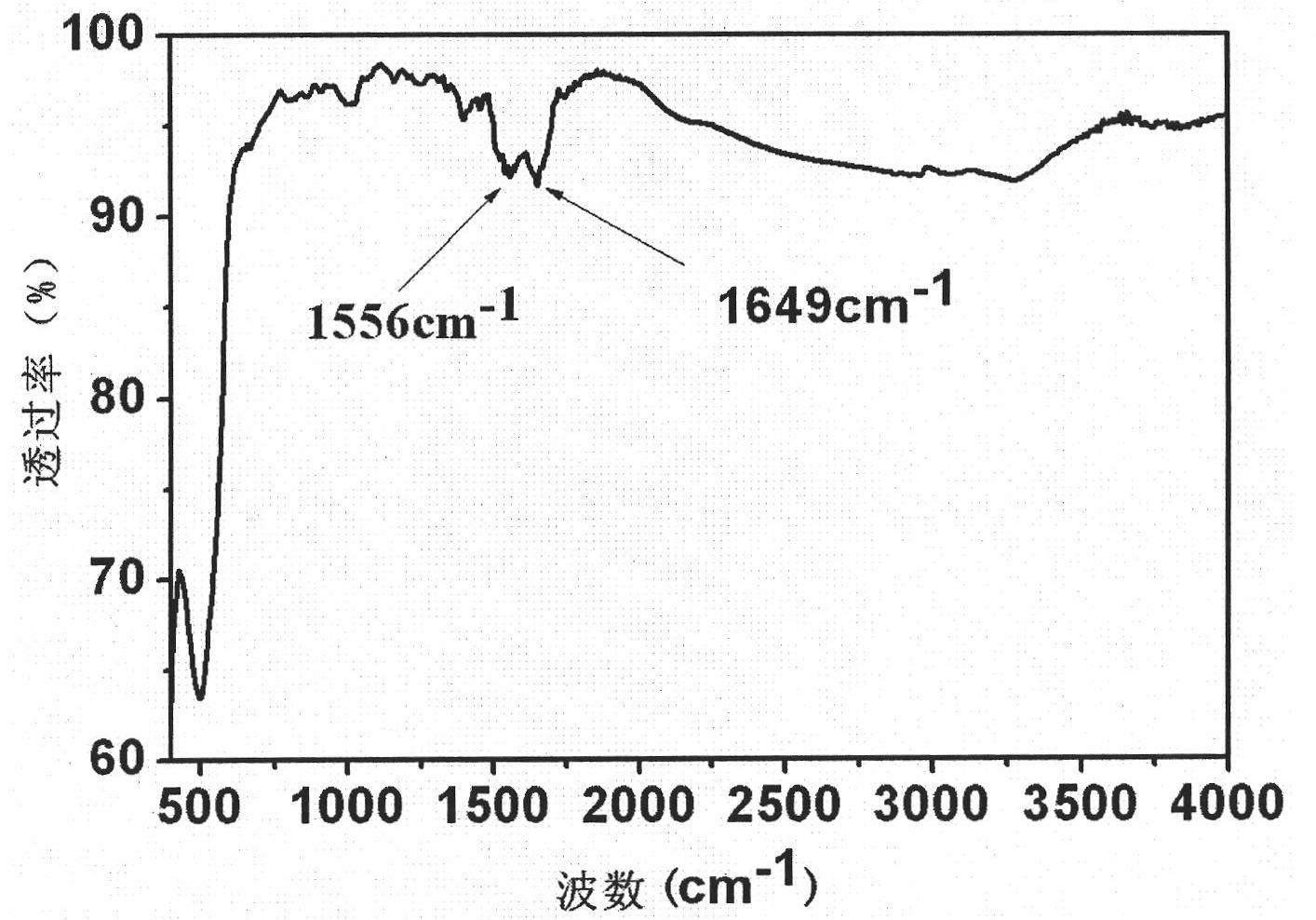

[0024] 3. Generating an enzyme coating layer on the surface of ZnO nanowires

[0025] Generating the enzyme coating layer by electrostatic adsorption: use K 2 HPO 4 and KH 2 PO 4 The standard solution was prepared as a 0.01M phosphate buffer solution with a Ph value of 6.86. Prepare glucose oxidase...

Embodiment 2

[0029] 1. Make a conductive layer on the substrate

[0030] A ZnO seed layer is grown on a polyimide substrate by magnetron sputtering to obtain a polyimide substrate with a ZnO seed layer.

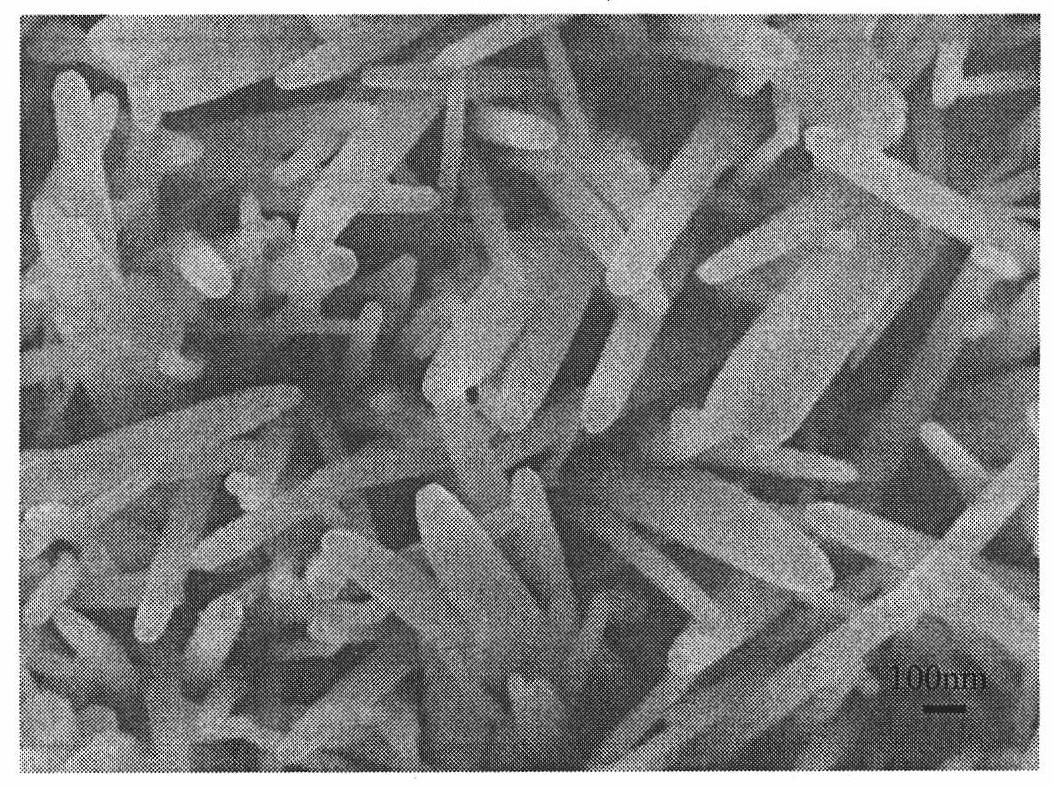

[0031] 2. Growth of ZnO nanowires on the conductive layer

[0032] ZnO nanowires were grown by electrochemical deposition: 0.005M zinc nitrate and 0.005M hexamethylenetetramine were used to prepare a growth solution and stirred evenly. The conductive layer on the substrate is used as the working electrode in the three-electrode system, the platinum sheet is used as the auxiliary electrode, and Ag / AgCl is used as the reference electrode. The growth temperature is 90° C., the growth time is 1 h, and the deposition potential is -1 V to complete the growth of ZnO nanowires.

[0033] 3. Generating an enzyme coating layer on the surface of ZnO nanowires

[0034] Generating the enzyme coating layer by electrostatic adsorption: use K 2 HPO 4 and KH 2 PO 4 The standard solution was prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com